Preparation method of modified pectin

A technology for modifying pectin and pectin, applied in the field of bioactive polysaccharide preparation, can solve the problems of uncontrollable oxidation process, low degradation efficiency, low reaction efficiency, etc., achieve good application potential, improve degradation efficiency, and product recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

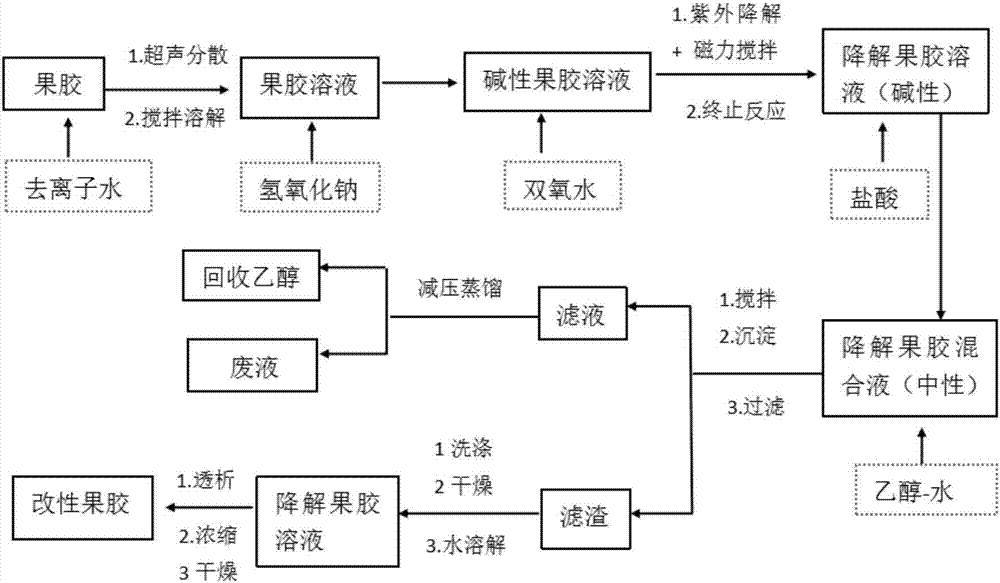

Image

Examples

Embodiment 1

[0034]Weigh 100mg of citrus pectin powder, add 20ml of deionized water, oscillate and mix evenly, insert the ultrasonic probe into the solution 2cm below, set the ultrasonic power to 200W, and ultrasonic time to 10min. Cool the pectin solution, and after the ultrasonic wave is over, continue magnetic stirring for 8 hours to fully dissolve the pectin to obtain a pectin solution; adjust the pH of the pectin solution to 12 with 0.5N NaOH solution to obtain an alkaline pectin solution; Add 20 μL of hydrogen peroxide dropwise to the glue solution, turn on the high-pressure mercury lamp, under the irradiation of 365nm ultraviolet light, stir and react at room temperature at 100rpm for 6h, then turn off the ultraviolet lamp, terminate the reaction, and obtain a degraded pectin solution (alkaline); use 0.3N HCl adjusted the reaction solution pH=7 to obtain a degraded pectin mixed solution (neutral); the resulting mixed solution was poured into 60 ml of ethanol-water solution with a vol...

Embodiment 2

[0037] Weigh 200mg of citrus pectin powder, add 20ml of deionized water, oscillate and mix well, insert the ultrasonic probe into the solution 2cm below, set the ultrasonic power to 200W, and ultrasonic time to 15min. Cool the pectin solution, and after the ultrasonic wave is over, continue magnetic stirring for 7 hours to fully dissolve the pectin to obtain a pectin solution; adjust the pH of the pectin solution to 12 with 0.5N NaOH solution to obtain an alkaline pectin solution; Add 30 μl of hydrogen peroxide dropwise to the glue solution, turn on the high-pressure mercury lamp, under the irradiation of 365nm ultraviolet light, stir the reaction at room temperature at 100rpm for 5h, then turn off the ultraviolet lamp, terminate the reaction, and obtain the degraded pectin solution (alkaline); use 0.3N HCl adjusted the reaction solution pH=7 to obtain a degraded pectin mixed solution (neutral); the resulting mixed solution was poured into 60 ml of ethanol-water solution with a...

Embodiment 3

[0040] Weigh 200mg of citrus pectin powder, add 20ml of deionized water, oscillate and mix well, insert the ultrasonic probe into the solution 2cm below, set the ultrasonic power to 200W, and ultrasonic time to 15min. Cool the pectin solution, and after the ultrasonic wave is over, continue magnetic stirring for 7 hours to fully dissolve the pectin to obtain a pectin solution; adjust the pH of the pectin solution to 12 with 0.5N NaOH solution to obtain an alkaline pectin solution; Add 30 μl of hydrogen peroxide dropwise to the glue solution, turn on the high-pressure mercury lamp, and under the irradiation of 365nm ultraviolet light, stir the reaction at a speed of 100 rpm at room temperature for 7 hours, then turn off the ultraviolet lamp, terminate the reaction, and obtain a degraded pectin solution (alkaline); use 0.3N HCl adjusted the reaction solution pH=7 to obtain a degraded pectin mixed solution (neutral); the resulting mixed solution was poured into 60 ml of ethanol-wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com