Stannic oxide hollow porous film gas sensitive element and preparation method thereof

A gas sensor and porous film technology, which is applied in the field of tin oxide hollow porous film gas sensor and its preparation, can solve the problem that the product cannot detect methyl mercaptan gas, the unfavorable gas to be tested is fully contacted, and the sensing film has no repeatability. To solve problems such as stability, the consistency and repeatability of the detection, the structure is reasonable, and the use is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

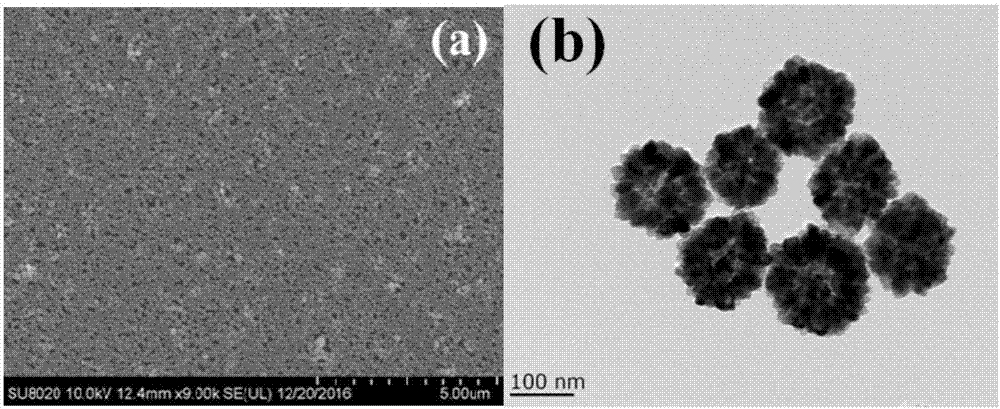

[0040] The concrete steps of preparation are:

[0041] Step 1, according to the weight ratio of tin tetrachloride pentahydrate, 5vol% ethanol aqueous solution and 40wt% hydrochloric acid solution is 0.5:150:1, first add tin tetrachloride pentahydrate into ethanol aqueous solution and stir for 10 minutes, A hydrochloric acid solution was added thereto to obtain a mixed solution. Then place the mixed solution at 150°C for 24 hours of airtight reaction, and then carry out solid-liquid separation and washing treatment; wherein, the solid-liquid separation treatment is centrifugation, the rotation speed is 6000r / min, the time is 6min, and the washing treatment is to use The deionized water and ethanol alternately wash the separated solid matter twice, and the separation of the solid matter during cleaning is centrifugal separation to obtain tin oxide hollow spheres.

[0042] Step 2, first disperse the tin oxide hollow spheres in ethanol to obtain a 10 g / L tin oxide hollow sphere e...

Embodiment 2

[0045] The concrete steps of preparation are:

[0046] Step 1, according to the weight ratio of tin tetrachloride pentahydrate, 16vol% ethanol aqueous solution and 39wt% hydrochloric acid solution is 0.58:125:1, first add tin tetrachloride pentahydrate into ethanol aqueous solution and stir for 15 minutes, A hydrochloric acid solution was added thereto to obtain a mixed solution. Then place the mixed solution at 163°C for 19.3 hours in closed reaction, and then carry out solid-liquid separation and washing treatment; wherein, the solid-liquid separation treatment is centrifugation, the rotation speed is 7000r / min, the time is 5.5min, and the washing treatment In order to use deionized water and ethanol to carry out 2 alternate cleanings on the separated solid matter, the separation of the solid matter during cleaning is centrifugal separation to obtain tin oxide hollow spheres.

[0047] Step 2, first disperse the tin oxide hollow spheres in ethanol to obtain a 15 g / L tin oxid...

Embodiment 3

[0050] The concrete steps of preparation are:

[0051] Step 1, according to the weight ratio of tin tetrachloride pentahydrate, 28vol% ethanol aqueous solution and 38wt% hydrochloric acid solution is 1.25:100:1, first add tin tetrachloride pentahydrate into ethanol aqueous solution and stir for 20min, A hydrochloric acid solution was added thereto to obtain a mixed solution. Then place the mixed solution at 175°C for 14.5 hours in a closed reaction, and then carry out solid-liquid separation and washing treatment; wherein, the solid-liquid separation treatment is centrifugation, the rotation speed is 8000r / min, the time is 5min, and the washing treatment is The separated solid matter was alternately washed three times with deionized water and ethanol, and the separation of the solid matter during washing was centrifuged to obtain tin oxide hollow spheres.

[0052] Step 2, first disperse the tin oxide hollow spheres in ethanol to obtain a 20 g / L tin oxide hollow sphere ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com