Light-emitting diode epitaxial wafer and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of unclear well-barrier interface and low crystal quality of quantum wells, and achieves good thermal conductivity, saving process flow, and thermal stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

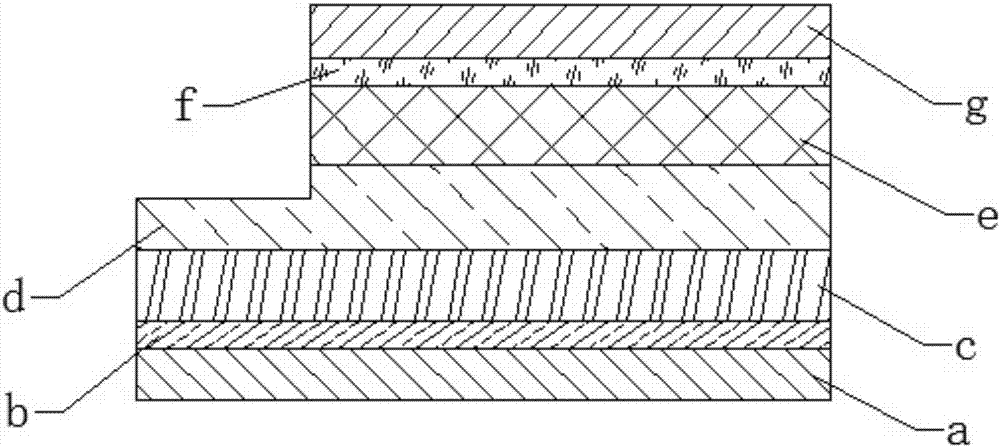

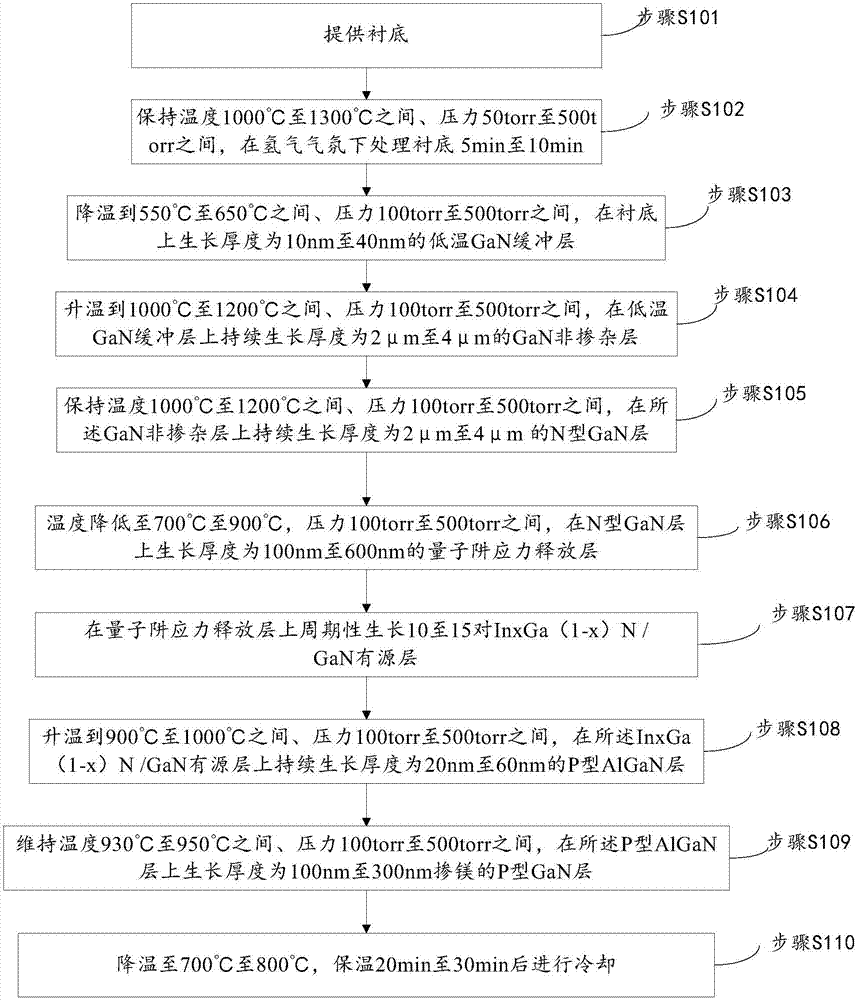

[0065] refer to figure 2 and image 3 , the present embodiment provides a method for manufacturing a light-emitting diode epitaxial wafer, comprising:

[0066] Step S101, providing a substrate 1;

[0067] Step S102, keeping the temperature between 1000° C. and 1300° C. and the pressure between 50 torr and 500 torr, and treating the substrate in a hydrogen atmosphere for 5 minutes to 10 minutes;

[0068] Step S103, lower the temperature to 550°C to 650°C, and the pressure to 100torr to 500torr, and grow a low-temperature GaN (gallium nitride) buffer layer 2 with a thickness of 10nm to 40nm on the substrate 1;

[0069] Step S104, raising the temperature to between 1000°C and 1200°C and the pressure between 100torr and 500torr, and continuously growing a GaN non-doped layer 3 with a thickness of 2 μm to 4 μm on the low-temperature GaN buffer layer 2;

[0070] Step S105, keeping the temperature between 1000° C. and 1200° C. and the pressure between 100 torr and 500 torr, and c...

Embodiment approach

[0081] As a preferred embodiment, the In x Ga (1-x) The In doping concentration of the N (x=0.015-0.25) well layer is 1E+20-5E+20.

[0082] As a preferred implementation manner, the magnesium doping concentration of the P-type AlGaN layer 6 is 5E+18-1E+19, and the Al doping concentration is 1E+20-3E+20.

[0083] As a preferred implementation manner, the Mg doping concentration of the P-type GaN layer 7 is 1E+19-1E+20.

[0084] The manufacturing method of the light-emitting diode epitaxial wafer provided by this embodiment can effectively improve the crystallization quality of the quantum well by adding the quantum well stress release layer, so that the interface between the well layer and the barrier layer of the quantum well is clearer and steeper, and the quantum well is more sensitive to electrons. and hole binding, thereby improving the luminous efficiency of the LED chip.

Embodiment 2

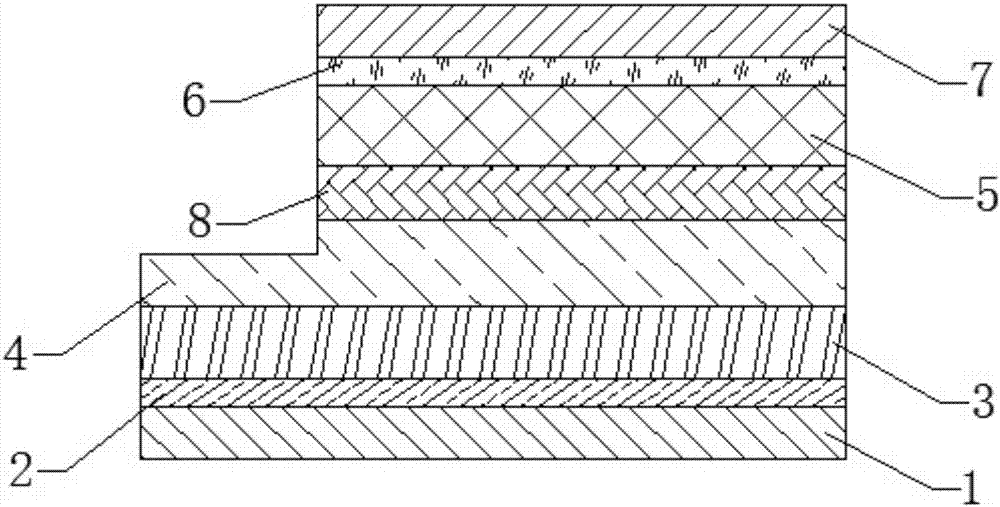

[0086] refer to image 3 , the present embodiment provides a method for fabricating an epitaxial wafer of a light emitting diode, comprising:

[0087] Step S201, providing a substrate 1;

[0088] Preferably, the substrate 1 is a sapphire substrate;

[0089] Step S202, maintaining the temperature at 1100° C., maintaining the pressure in the reaction chamber at 500 torr, and processing the substrate in a hydrogen atmosphere for 6 minutes;

[0090] Step S203, lowering the temperature to 550° C., maintaining the pressure of the reaction chamber at 500 torr, and growing a low-temperature GaN buffer layer 2 with a thickness of 20 nm on the substrate 1;

[0091] In step S204, the temperature is raised to 1100° C., the pressure of the reaction chamber is maintained at 200 torr, and a GaN non-doped layer 3 with a thickness of 3 μm is continuously grown on the low-temperature buffer layer 2 ;

[0092] Step S205, maintaining the temperature at 1100° C., maintaining the pressure of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com