Preparation method of yeast culture

A yeast culture and fermentation substrate technology, applied in the field of yeast solid fermentation, can solve the problems of complex composition, low fermentation level, unbalanced nutrition, etc., and achieve the effects of shortening fermentation time, improving nutritional value and making full use of it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

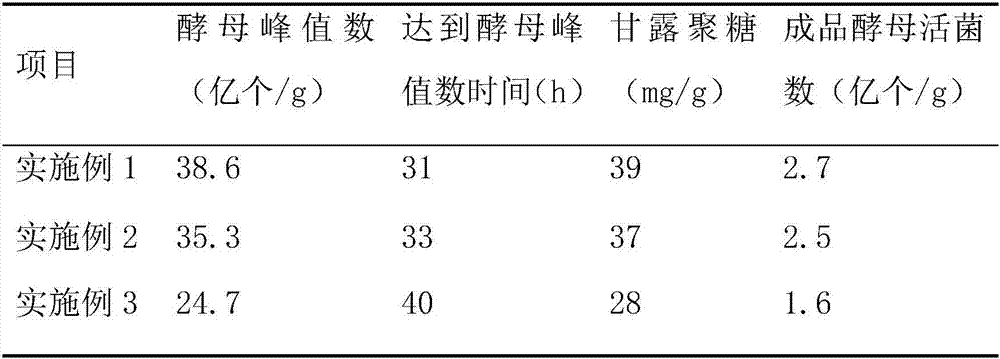

Examples

preparation example Construction

[0024] A kind of preparation method of yeast culture provided by the invention comprises the following steps:

[0025] Step (1) Carry out drying pretreatment on the fermentation substrate, specifically: the fermentation substrate is distiller's grains, and the water content of the distiller's grains is adjusted from 55-70% to 45-55%, specifically, according to the water content of the fermentation substrate rate, control the inlet air temperature at 300-400°C, keep the time for 10-15min, control the moisture evenly, and the error is within ±0.5%. Conditioned, pre-dried using a tumble drying process.

[0026] Step (2) mixing the dolomitic limestone powder into the fermentation substrate after drying and pretreatment, specifically, passing the dolomitic limestone powder through a 60-mesh sieve, and uniformly mixing the dolomitic limestone powder in a ratio of 1-5% to the fermentation substrate Among the materials, it is further preferred to use the local dolomitic limestone of ...

Embodiment 1

[0031] (1) Pre-dry the fermentation substrate, Maotai-flavored distiller's grains: accurately measure the moisture content of the raw material of Maotai-flavored distiller's grains, adjust the equipment parameters according to the moisture content of the fermentation substrate, and control the ventilation temperature to 300-400°C. The retention time is 10-15min, and the moisture content is 45-55%. In this embodiment, the moisture content is controlled at 55%, and the moisture is uniformly controlled, and the error is within ±0.5%.

[0032] (2) Pass the local dolomitic limestone powder of Maotai-flavored distiller's grains through a 60-mesh sieve, and evenly mix it into the fermentation substrate at a ratio of 1-5%, and the addition ratio is 5% in this embodiment.

[0033] (3) Add puffed corn flour at a ratio of 5-10%, and add K at a ratio of 0.2-0.6%. 2 HPO 4 , and mix well. The addition ratio of this embodiment is 5% of puffed corn flour, K 2 HPO 4 0.3%, the two are adde...

Embodiment 2

[0039] (1) Pass the local dolomitic limestone powder of Maotai-flavored distiller's grains through a 60-mesh sieve, and evenly mix it into the fermentation substrate at a ratio of 1-5%, and the addition ratio is 5% in this embodiment.

[0040] (2) Add puffed corn flour at a ratio of 5-10%, and add K at a ratio of 0.2-0.6%. 2 HPO 4 , and mix well. The addition ratio of this embodiment is 5% of puffed corn flour, K 2 HPO 4 0.3%, the two are added in no order, and the two can also be mixed and added.

[0041] (3) Inoculate the activated Saccharomyces cerevisiae into the fermentation substrate at a ratio of 0.1-1%, and stir evenly. In this embodiment, the addition ratio of yeast is selected as 0.1%. The yeast is a special feed yeast provided by Angel Yeast. The activation method is: 2% rehydration and activation of sugar water at a temperature of 30-35°C, adding 10 kg of sugar water to each kilogram of dry yeast, stirring evenly, and activating for 15-30 minutes.

[0042] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com