A preparation method of porous hydroxyapatite particles for deep adsorption of copper ions in solution

A hydroxyapatite, deep adsorption technology, applied in the direction of ion exchange, selective adsorption, ion exchange regeneration, etc., can solve the problems of long standing adsorption time, failure to meet the discharge requirements, high residual ion concentration, etc., and achieve adsorption The effect of fast speed, high opening rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

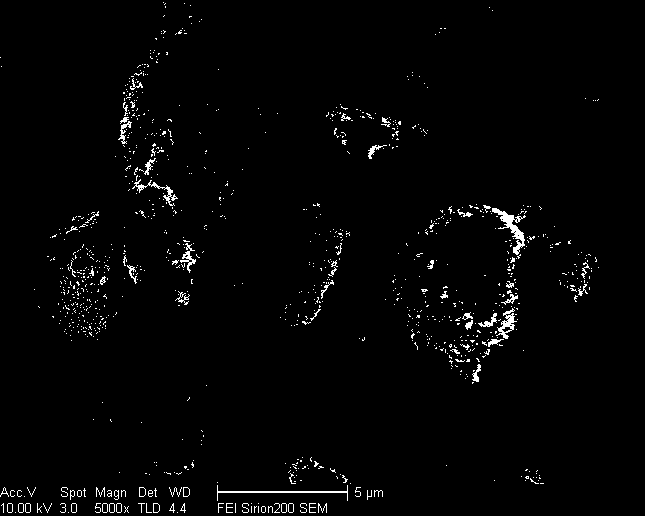

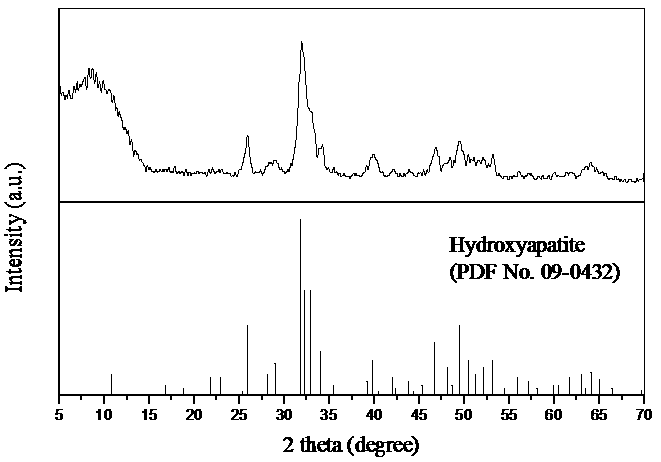

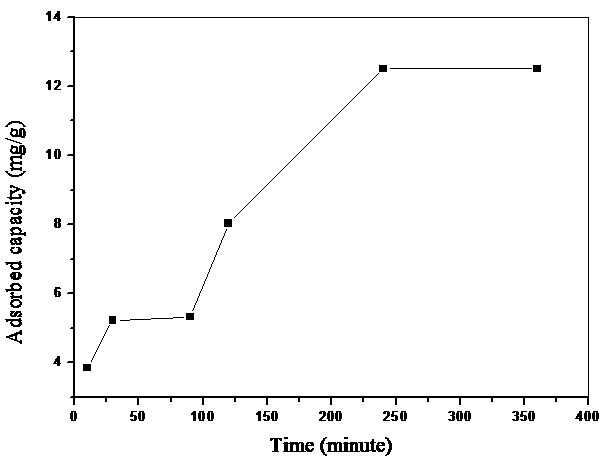

Image

Examples

Embodiment 1

[0019] (1) Prepare a citric acid solution with a concentration of 0.0520 moles per liter, add calcium hydroxide to make the concentration 0.6757 moles per liter, then drop in a phosphoric acid solution with a concentration of 0.8163 moles per liter, and stop the dripping when the pH=8.80 , after stirring for 1 hour, stand and age for 18 hours;

[0020] (2) Centrifuge the reaction solution prepared in step (1), and wash the obtained precipitate with ammonium chloride solution, wherein the mass ratio of ammonium chloride to calcium hydroxide is 1:2.5, and then centrifuge After separating and dispersing the obtained precipitate into an aqueous solution, add polyvinyl alcohol with an average degree of polymerization of 1750 so that the mass ratio of polyvinyl alcohol added to calcium hydroxide added is 0.002:2.5, and hydrothermally treat at 150°C for 6 Cool to room temperature after 1 hour;

[0021] (3) Centrifuge the colloidal solution prepared in step (2) to obtain a precipitat...

Embodiment 2

[0030] (1) Prepare a citric acid solution with a concentration of 0.0520 moles per liter, add calcium hydroxide to make the concentration 0.6757 moles per liter, then add dropwise a phosphoric acid solution with a concentration of 0.8163 moles per liter, and stop the dripping when pH=8.80 , after stirring for 1 hour, stand and age for 18 hours;

[0031](2) Centrifuge the colloidal solution prepared in step (1) to obtain a precipitate, and wash the obtained precipitate with an ammonium chloride solution, wherein the mass ratio of the amount of ammonium chloride to the amount of calcium hydroxide is 1: 2.5, after centrifuging and dispersing the obtained precipitate into an aqueous solution, add polyvinyl alcohol with an average degree of polymerization of 1750, so that the mass ratio of the amount of polyvinyl alcohol added to the amount of calcium hydroxide added is 0.001:2.5, at 150° Cool to room temperature after hydrothermal treatment under C for 6 hours;

[0032] (3) Centr...

Embodiment 3

[0035] (1) Prepare a citric acid solution with a concentration of 0.0520 moles per liter, add calcium hydroxide to make the concentration 0.6757 moles per liter, then drop in a phosphoric acid solution with a concentration of 0.8163 moles per liter, and stop the dripping when the pH=8.80 , stirred for 1 hour and left to age for 18 hours;

[0036] (2) Centrifuge the reaction solution prepared in step (1), and wash the obtained precipitate with ammonium chloride solution, wherein the mass ratio of ammonium chloride to calcium hydroxide is 1:2.5, and then centrifuge After separating and dispersing the obtained precipitate into an aqueous solution, add polyvinyl alcohol with an average degree of polymerization of 1750, so that the mass ratio of the amount of polyvinyl alcohol added to the amount of calcium hydroxide added is 0.003:2.5, and hydrothermally treat at 150°C for 6 Cool to room temperature after 1 hour;

[0037] (3) Centrifuge the colloidal solution prepared in step (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com