A preparation method of copper/carbon-based composite material for pantograph sliding plate

A technology for pantograph slides and composite materials, applied in carbon preparation/purification, metal material coating process, coating, etc., can solve the problems of limited application range, easy cracks, etc., to improve interface bonding and avoid cracks Produces the effect of low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

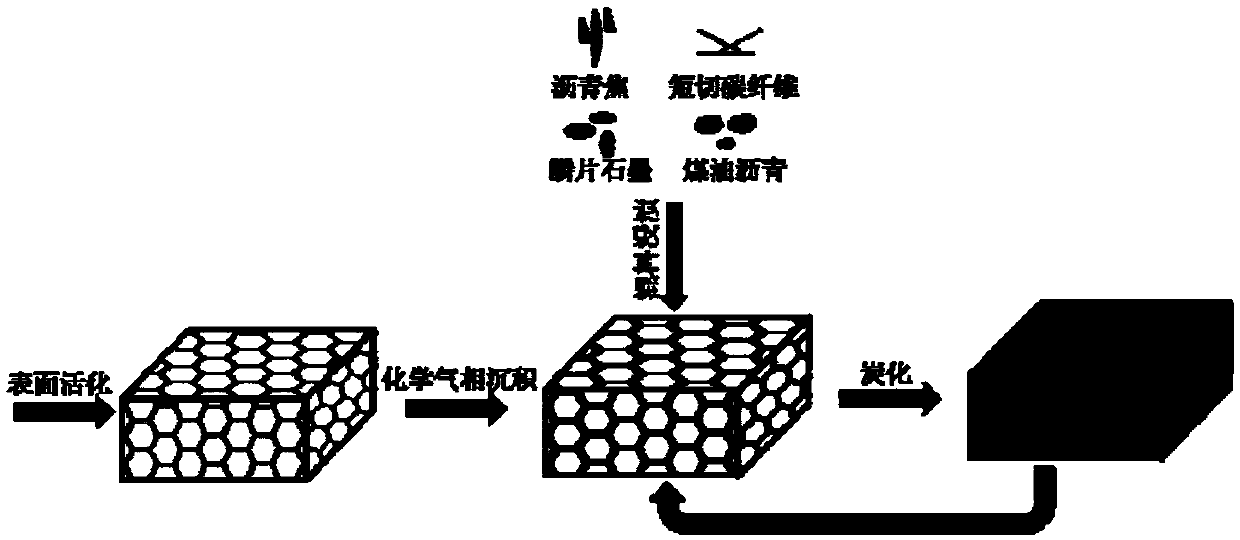

Method used

Image

Examples

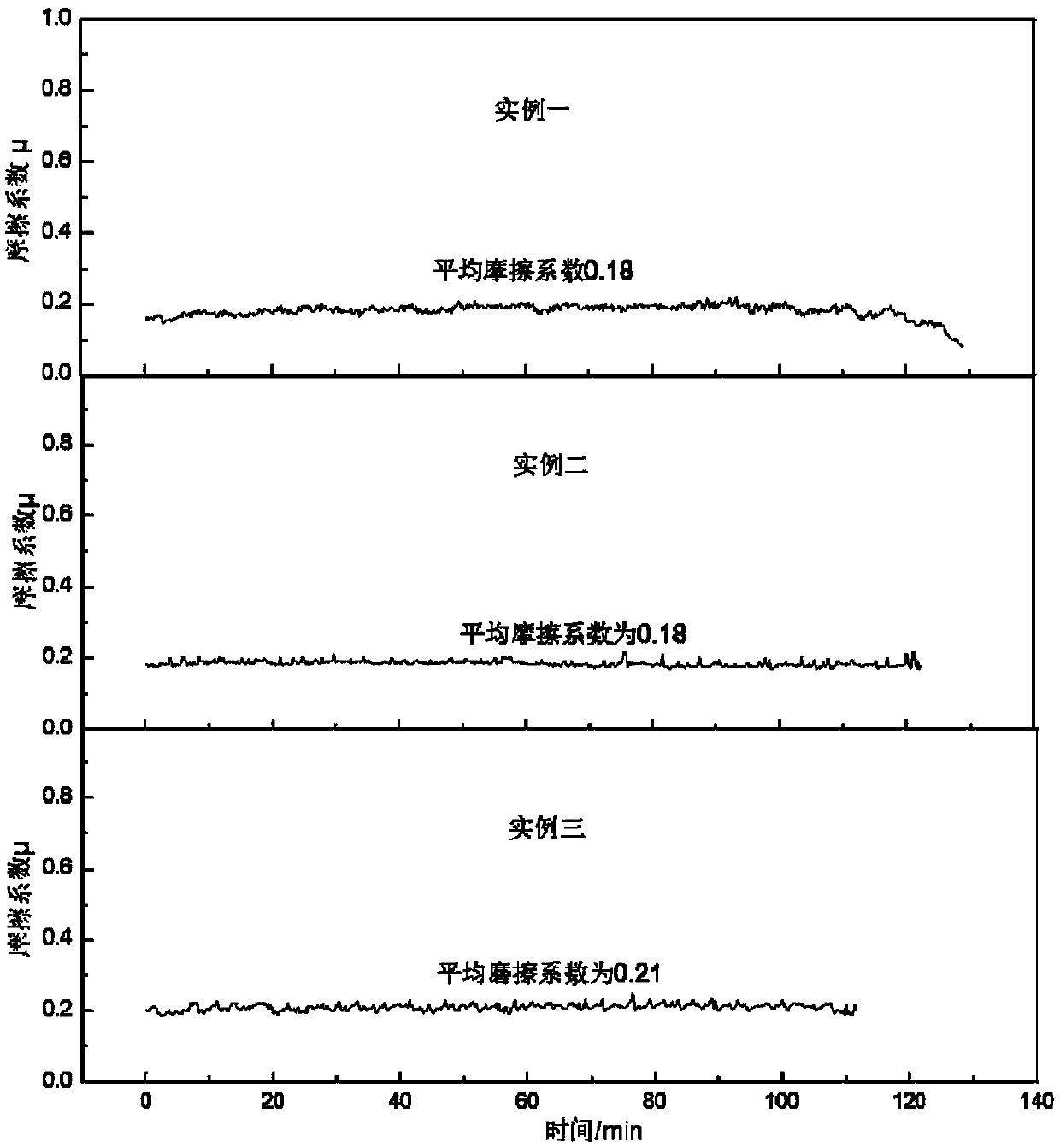

example 1

[0067] The preparation process and process parameters are:

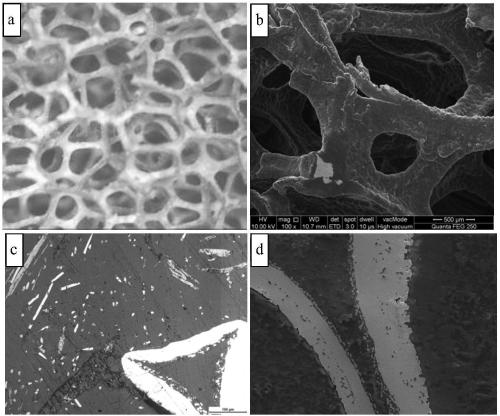

[0068] (1) Select the size and performance of copper foam: pore diameter 1mm, porosity 90%, copper content greater than 99%, pore number 30PPI, connectivity rate greater than 98%, density 0.45g / cm 2 , the size is 40mm*100mm*100mm. Use 10% dilute hydrochloric acid to deoxidize and activate the copper foam under ultrasonic waves, then wash it with distilled water, and dry it for later use.

[0069] (2) The chemical vapor infiltration process is used to densify the foamed copper preform with pyrolytic carbon. The reaction gas is prepared from carbon source gas and dilution gas. The carbon source gas is propylene and the dilution gas is N. 2 , the dilution ratio is carbon source gas: dilution gas = 1:6, the deposition temperature is 800°C, and the total deposition time is 50 hours;

[0070] (3) The content of pitch coke is 20%, and the pitch coke is 100 mesh; the content of chopped carbon fiber is 8%, and the length of...

example 2

[0074] The preparation process and process parameters are:

[0075] (1) Select the size and performance of copper foam: pore diameter 1mm, porosity 90%, copper content greater than 99%, pore number 20PPI, connectivity rate greater than 98%, density 0.45g / cm 2 , the size is 40mm*100mm*100mm. Use 10% dilute hydrochloric acid to deoxidize and activate the copper foam under ultrasonic waves, then wash it with distilled water, and dry it for later use.

[0076] (2) The chemical vapor infiltration process is used to densify the foamed copper preform with pyrolytic carbon. The reaction gas is prepared from carbon source gas and dilution gas. The carbon source gas is propylene and the dilution gas is N. 2 , the dilution ratio is carbon source gas: dilution gas = 1:6, the deposition temperature is 800°C, and the total deposition time is 50 hours;

[0077] (3) The content of pitch coke is 30%, and the pitch coke is 100 mesh; the content of chopped carbon fiber is 8%, and the length of...

example 3

[0081] The preparation process and process parameters are:

[0082] (1) Select the size and performance of copper foam: pore diameter 1mm, porosity 85%, copper content greater than 99%, pore number 30PPI, connectivity rate greater than 98%, density 0.51g / cm 2 , the size is 40mm*100mm*100mm. Use 10% dilute hydrochloric acid to deoxidize and activate the copper foam under ultrasonic waves, then wash it with distilled water, and dry it for later use.

[0083] (2) The chemical vapor infiltration process is used to densify the foamed copper preform with pyrolytic carbon. The reaction gas is prepared from carbon source gas and dilution gas. The carbon source gas is propylene and the dilution gas is N. 2 , the dilution ratio is carbon source gas: dilution gas = 1:6, the deposition temperature is 800°C, and the total deposition time is 50 hours;

[0084] (3) The pitch coke content is 20%, and the pitch coke is 100 mesh; the chopped carbon fiber content is 15%, and the short fiber le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com