Process and system for treating power plant wastewater

A technology of treatment process and treatment system, which is applied in the field of treatment process and treatment system of power plant wastewater to achieve the effects of saving water resources, reducing consumption and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

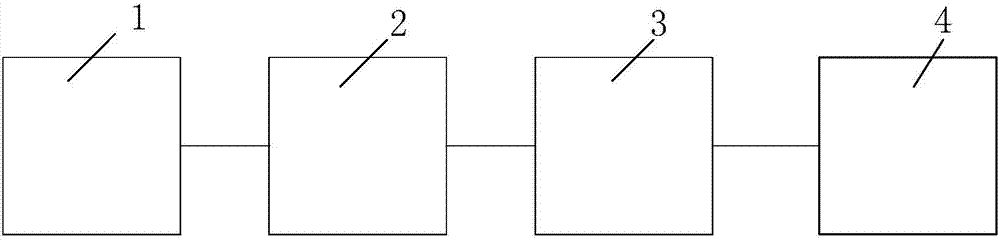

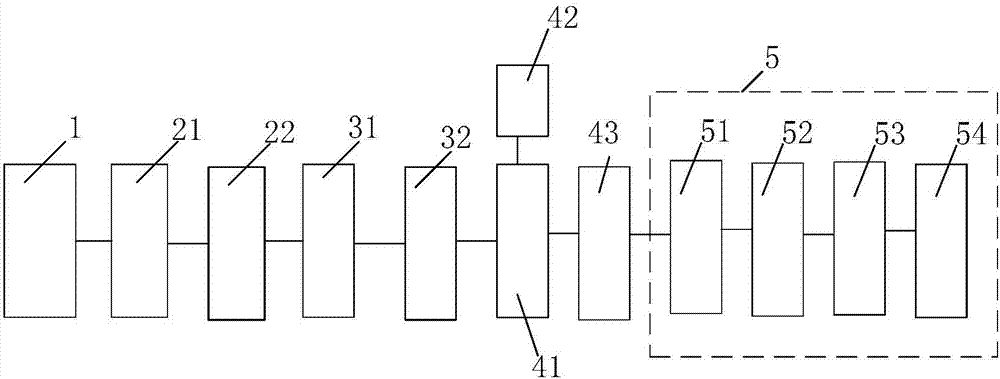

[0053] A 2×300MW coal gangue power generation project adopts a circulating fluidized bed boiler and a direct air-cooled steam turbine generator set. h of waste water needs to be treated for reuse. use figure 2 The treatment system shown is for wastewater treatment. The treatment system also includes wastewater collection equipment and lift pumps. Among them, the lime softening equipment is a high-density pool. The specific treatment process includes:

[0054] Collect the waste water into the waste water collection equipment, and use the lift pump to pump the waste water to the high-density pool with built-in lime milk for lime softening;

[0055] The above-mentioned waste water after the lime softening enters into the sand filter device 21 through the softened water outlet of the above-mentioned lime softening device 1 to filter sand; the waste water after the sand filter enters the ultrafiltration device 22 through the filter liquid outlet for further filtration, and the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com