Spray tower tray reactor, and system and technology for producing propylene glycol monomethyl ether through using reactor

A technology of propylene glycol monomethyl ether and disc reactor, which is applied in the chemical industry and can solve problems such as low production efficiency, high energy consumption for separation, and unfavorable large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

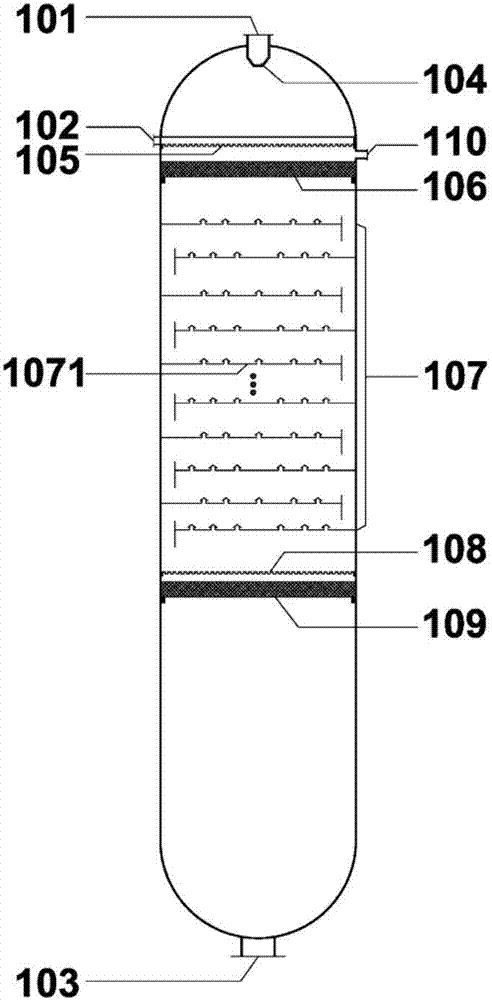

[0083] A spray tray reactor, such as figure 1 As shown, including the reactor body, the reactor body is provided with a cavity;

[0084] The top, sidewall and bottom of the reactor body are respectively provided with a first feed port 101, a second feed port 102 and a discharge port 103;

[0085] In the above chamber, from top to bottom, an atomizing nozzle 104 matched with the first feed port 101, a first distributor 105 (pipe distributor) matched with the second feed port 102, and a second distributor 106 are arranged sequentially. (sintered plate distributor), multistage tray 107 (made up of 24 bubble cap trays 1071), liquid collector 108 and the third distributor 109 (100 mesh screen distributor);

[0086] A third feed port 110 is provided on the side wall of the reactor between the first distributor 105 and the second distributor 106;

[0087] Wherein, the inner diameter of the reactor is 0.3m, the distance from the top to the bottom of the cavity is 1.5m, and the atomi...

Embodiment 2

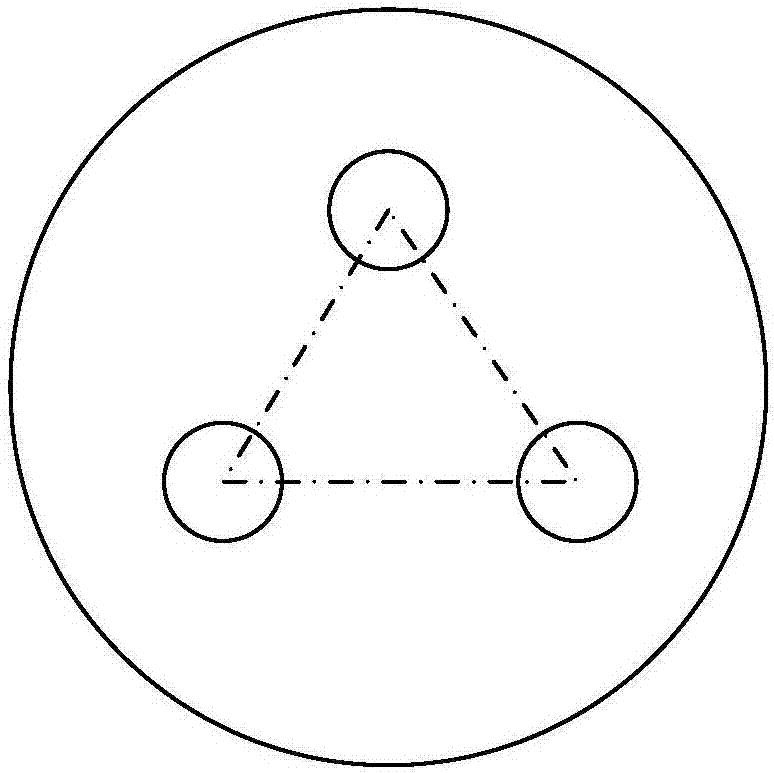

[0089] A spray tray reactor, the only difference from Example 1 is that the atomization nozzle includes 3 openings of 60° atomization nozzles, such as Figure 2b As shown, the three atomizing nozzles are distributed in an equilateral triangle, and the distance between the atomizing nozzles and the pipe distributor is 0.2m.

Embodiment 3

[0091] A spray tray reactor, the only difference with embodiment 1 is that the atomization nozzle comprises 4 openings of 45 ° of atomization nozzles, such as Figure 2c As shown, the four atomizing nozzles are distributed in a square shape, and the distance between the atomizing nozzles and the pipe distributor is 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com