Extraction method for natural high-purity mogroside

A technology of mogroside and extraction method, which is applied in the field of extraction of natural high-purity mogroside, can solve the problems of cumbersome steps, time-consuming and labor-consuming, and large environmental pollution, and achieve the goal of improving extraction efficiency, reducing production costs, and simple extraction process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

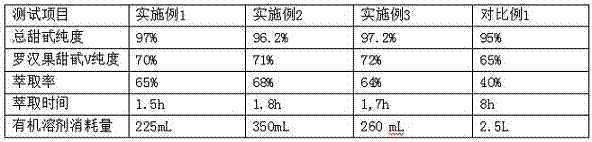

Examples

Embodiment 1

[0021] Wash the Luo Han Guo with clean water, dry it naturally, dry it in a vacuum oven at 40°C for 11 hours, use a traditional Chinese medicine pulverizer to pulverize it, pass it through a 60-mesh sieve, and then pulverize the sieved powder to obtain nano-scale super Fine powder: after mixing 300g of Luo Han Guo superfine powder with 3L of water, after ultrasonication for 20 minutes at 200W and 45°C, after filtration, the filter residue was ultrasonically extracted twice again, the extracts were combined, and the extraction extract was obtained by vacuum distillation; Mix a certain amount of 200mL tetrahydrofuran, 100mL n-octanol, and 700mL water evenly, and let it stand naturally for 1 hour. The system is phase-separated, and the upper phase is removed to obtain a nano-sized supramolecular solvent; the extract is dissolved in water to obtain 0.3 g / mL extract water solution, take 1L extract water and add 75mL supramolecular solvent, vortex for 20 seconds, centrifuge, remove t...

Embodiment 2

[0023] Wash the grosvenoria grosvenori with clear water, dry it naturally, dry it in a vacuum oven at 45°C for 10 hours, crush it with a traditional Chinese medicine grinder, pass it through a 60-mesh sieve, and further crush the sieved powder to obtain nano-scale super Fine powder: after mixing 500g of Luo Han Guo superfine powder with 12L of water, ultrasonication was performed at 250W and 50°C for 25 minutes, after filtration, the filter residue was ultrasonically extracted 3 times again, the extracts were combined, and the extract was obtained by distillation under reduced pressure; Mix a certain amount of 350mL tetrahydrofuran, 200mL n-decyl alcohol, and 1000mL water evenly, and let it stand naturally for 1 hour. The system is phase-separated, and the upper phase is removed to obtain a nano-sized supramolecular solvent; the extract is dissolved in water to obtain 0.35 g / mL extract water solution, take 1.5L extract water and add 150mL supramolecular solvent, vortex for 15 s...

Embodiment 3

[0025] Wash the Luo Han Guo with clean water, dry it naturally, dry it in a vacuum oven at 40°C for 12 hours, crush it with a traditional Chinese medicine grinder, pass it through a 60-mesh sieve, and further crush the sieved powder to obtain nano-scale super Fine powder: after mixing 400g of Luo Han Guo superfine powder with 10L of water, ultrasonication was performed at 300W and 40°C for 25 minutes, and after filtration, the filter residue was ultrasonically extracted twice again, the extracts were combined, and the extraction extract was obtained by distillation under reduced pressure; Mix a certain amount of 200mL tetrahydrofuran, 150mL n-hexanol, and 800mL water evenly, and let it stand naturally for 1 hour. The system is phase-separated, and the upper phase is removed to obtain a nano-sized supramolecular solvent; the extract is dissolved in water to obtain 0.25g / mL extract water solution, take 1.5L extract water and add 100mL supramolecular solvent, vortex for 20 second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com