Ultraviolet light curing black adhesive and preparation method thereof

An ultraviolet light and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of adhesive force and double 85 test failing to meet the requirements, and achieve easy industrial implementation, adhesion Good junction performance and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

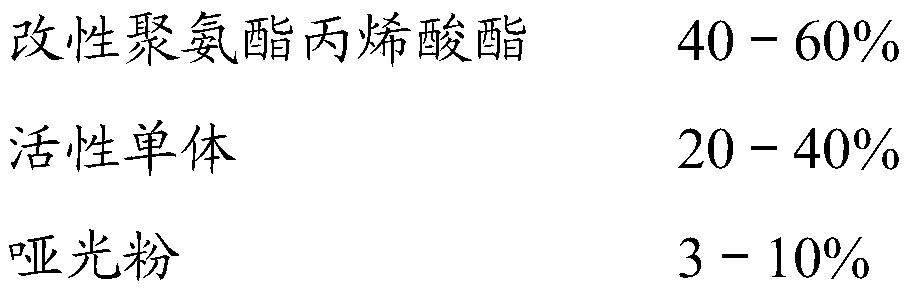

[0044] The UV-curable black adhesive of this embodiment is prepared from the following raw materials in terms of mass percentage:

[0045]

[0046] The modified polyurethane acrylate of this embodiment is prepared from the following raw materials: a mixture of polyether diol and mercaptan, diisocyanate, hydroxyl-functionalized acrylate, catalyst and polymerization inhibitor; wherein polyether diol is poly Ethylene glycol, thiol is ethylene glycol bis(3-mercaptopropionate), the molar ratio of polyether diol and thiol is 4.5:1; diisocyanate is isophorone diisocyanate with a molar ratio of 3:1 A combination of isocyanate and toluene diisocyanate; the hydroxy-functionalized acrylate is hydroxyethyl acrylate, and the catalyst and inhibitor are dibutyltin dilaurate and 2,6-di-tert-butyl-4-methylphenol, respectively; poly The molar ratio of the mixture of ether dihydric alcohol and thiol, diisocyanate, and hydroxyl-functionalized acrylate is 1:2:2.1; the addition amount of catalys...

Embodiment 2

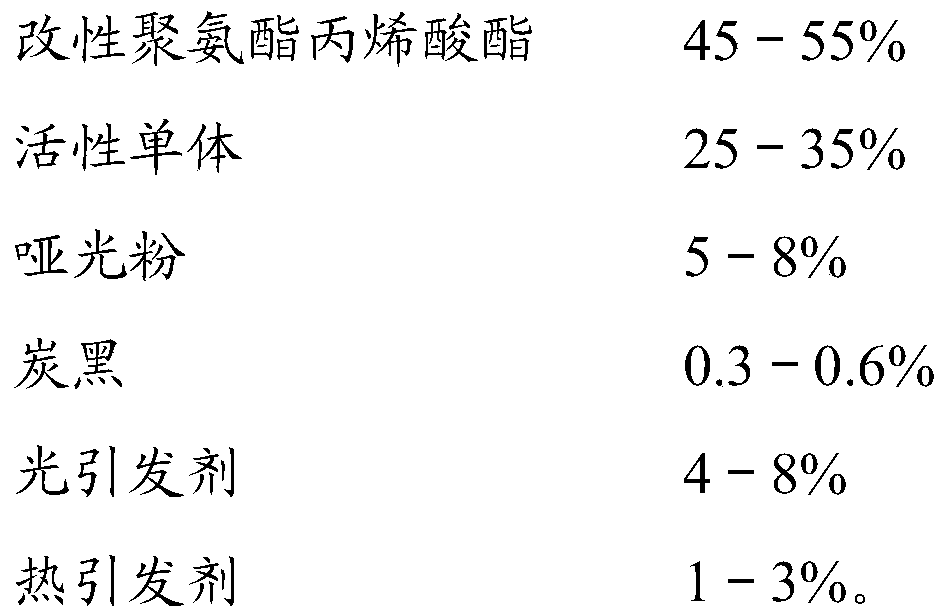

[0053] The UV-curable black adhesive of this embodiment is prepared from the following raw materials in terms of mass percentage:

[0054]

[0055] The modified polyurethane acrylate of this embodiment is prepared from the following raw materials: a mixture of polyether diol and mercaptan, diisocyanate, hydroxyl-functionalized acrylate, catalyst and polymerization inhibitor; wherein polyether diol is poly Propylene glycol, thiol is 1,4-butanediol bis(3-mercaptopropionate), the molar ratio of polyether diol and thiol is 4.5:1; diisocyanate is isophor with a molar ratio of 3:1 A combination of ketone diisocyanate and toluene diisocyanate; the hydroxy-functionalized acrylate is hydroxypropyl acrylate, and the catalyst and inhibitor are dibutyltin dilaurate and 2,6-di-tert-butyl-4-methylphenol, respectively The mol ratio of the mixture of polyether glycol and mercaptan, diisocyanate, hydroxyl functionalized acrylate is 1:2:2.1; The add-on of catalyst and stopper is respectively...

Embodiment 3

[0059] The UV-curable black adhesive of this embodiment is prepared from the following raw materials in terms of mass percentage:

[0060]

[0061] The modified polyurethane acrylate of this embodiment is prepared from the following raw materials: a mixture of polyether diol and mercaptan, diisocyanate, hydroxyl-functionalized acrylate, catalyst and polymerization inhibitor; wherein polyether diol is poly (1,4-butanediol), the mercaptan is ethylene glycol bis(3-mercaptopropionate), the molar ratio of polyether diol and mercaptan is 4.5:1; the molar ratio of diisocyanate is 3:1 A combination of isophorone diisocyanate and toluene diisocyanate; the hydroxy-functional acrylate is hydroxyethyl acrylate, and the catalyst and inhibitor are dibutyltin dilaurate and 2,6-di-tert-butyl-4 - methylphenol; the molar ratio of the mixture of polyether diol and mercaptan, diisocyanate, hydroxyl-functionalized acrylate is 1:2:2.1; the addition amount of catalyst and polymerization inhibitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com