Optical adhesive and preparation method thereof

An adhesive and optical technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of poor performance such as boiling water resistance and solvent resistance, and it is difficult to meet the requirements of 5B adhesion of 100 grids. Curing Slow speed and other problems, to achieve superior moisture and heat resistance, promote light curing reaction, increase the effect of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

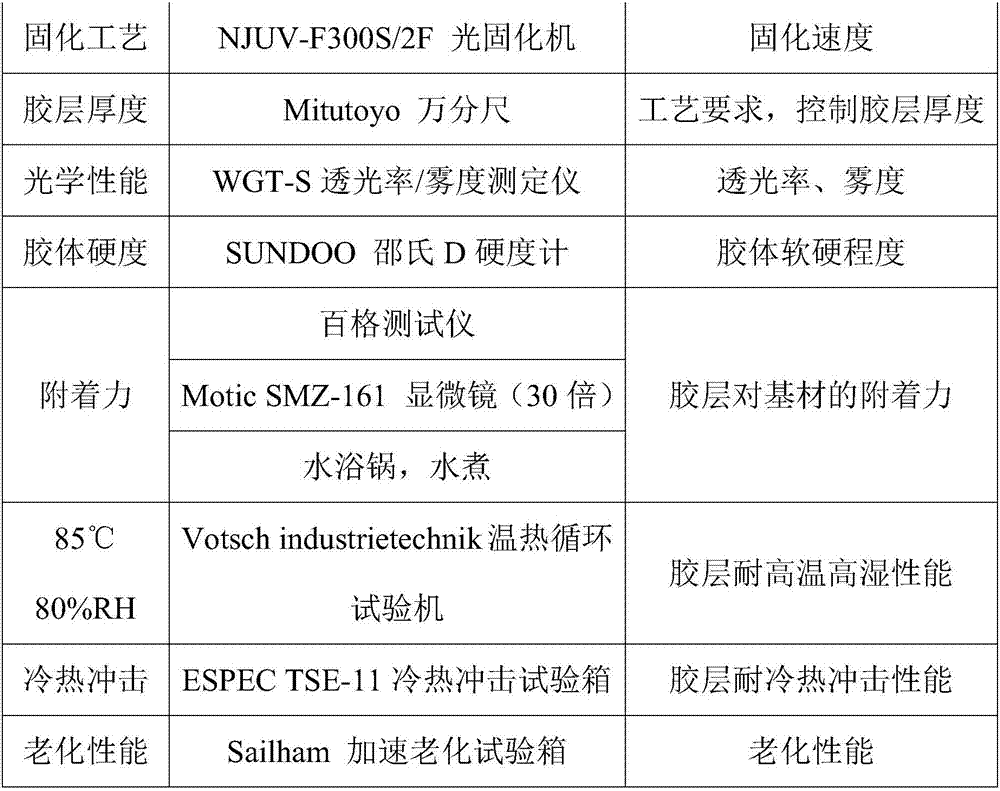

[0053] An embodiment of the present invention proposes a preparation method of an optical adhesive, which comprises: 50-70 parts of polyester polyurethane acrylate, 10-40 parts of reactive diluent, 1-5 parts of photoinitiator, defoamer 0.2-0.8 parts, 0.5-1.0 parts of wetting and leveling agent, 0.2-0.4 parts of surfactant, 0.5-4 parts of siloxane coupling agent, 0.5-2.0 parts of thixotropic agent, 1-10 parts of filler, after planetary Type defoaming mixer 1800-2200r / min, after stirring for 5-10min, filter and pack into the needle tube, and use a high-speed centrifugal defoamer to defoam again, the defoaming rate is 2300-2800r / min, and the defoaming time is 3-5min , to obtain the above-mentioned optical adhesive.

[0054] A kind of polyester polyurethane acrylate A that an embodiment of the present invention proposes, methyl propylene glycol 180g, propylene glycol 76g, trimethylolpropane 70g, adipic acid 145g, succinic acid 177g under the condition of band water solvent Esteri...

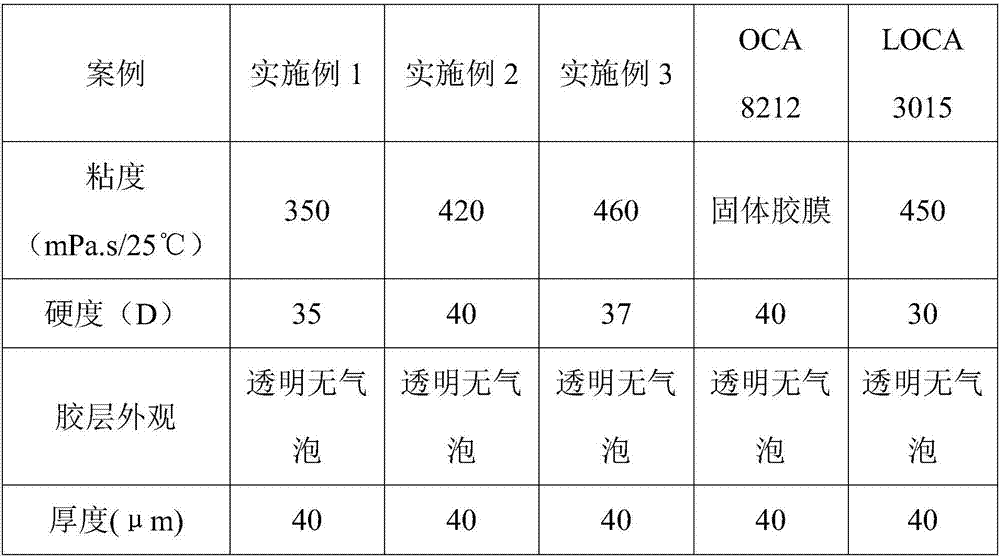

Embodiment 1

[0057] The preparation method of the optical adhesive proposed by an embodiment of the present invention, accurately weighed by weight (using an electronic scale with an accuracy of 0.01g), self-synthesized polyester urethane acrylate A: 20g, self-synthesized polyester urethane acrylate B: 35g; THFA: 18g; HPMA: 20g; AA: 6.6g; Coupling agent A-174: 1.5g; LBR-307: 2g; Photoinitiator 1173: 2.0g; Photoinitiator TPO: 1.5g; Leveling agent WT270: 0.5g; defoamer 931: 0.3g; thixotropic agent 3440: 1.3g; surfactant FL2300: 0.2g; After 10 minutes, filter through a filter with a mesh size of 1000 or more and pack into needle tubes, and use a high-speed centrifugal defoamer to defoam again. The defoaming rate is 2300-2800r / min, and the defoaming time is 3-5min. The optical adhesive is obtained; the appearance of the optical adhesive Colorless and transparent, the viscosity is controlled at 350mPa.s / 25℃.

[0058] The optical adhesive proposed by an embodiment of the present invention is pr...

Embodiment 2

[0074] The preparation method of the optical adhesive proposed by an embodiment of the present invention, accurately weighed by weight (using an electronic scale with an accuracy of 0.01g), self-synthesized polyester urethane acrylate A: 35g, self-synthesized polyester urethane acrylate B: 35g; THFA: 16g; HPMA: 15g; AA: 5.0g; DMAA: 10g; coupling agent A-174: 2.0g; filler LBR-307: 3g; photoinitiator 1173: 2.5g; g; leveling agent WT270: 0.5g; defoamer 931: 0.5g; thixotropic agent 3440: 1.0g; surfactant FL2300: 0.2g; min, after stirring for 5-10 minutes, filter through a filter of 1000 mesh or more and put it into a needle tube, and use a high-speed centrifugal defoamer to defoam again. The defoaming rate is 2300-2800r / min, and the defoaming time is 3-5min. Adhesive; optical adhesive is colorless and transparent in appearance, and its viscosity is controlled at 420mPa.s / 25℃.

[0075] The optical adhesive proposed by an embodiment of the present invention is prepared by the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com