Preparation method and application of space charge separation type composite photocatalyst

A space charge, photocatalytic reactor technology, applied in the field of photocatalysis, can solve the problems of photogenerated carrier separation efficiency limitation, low photocatalytic hydrogen production efficiency, load, etc., achieving good photocatalytic stability, simple synthesis process, effect on sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

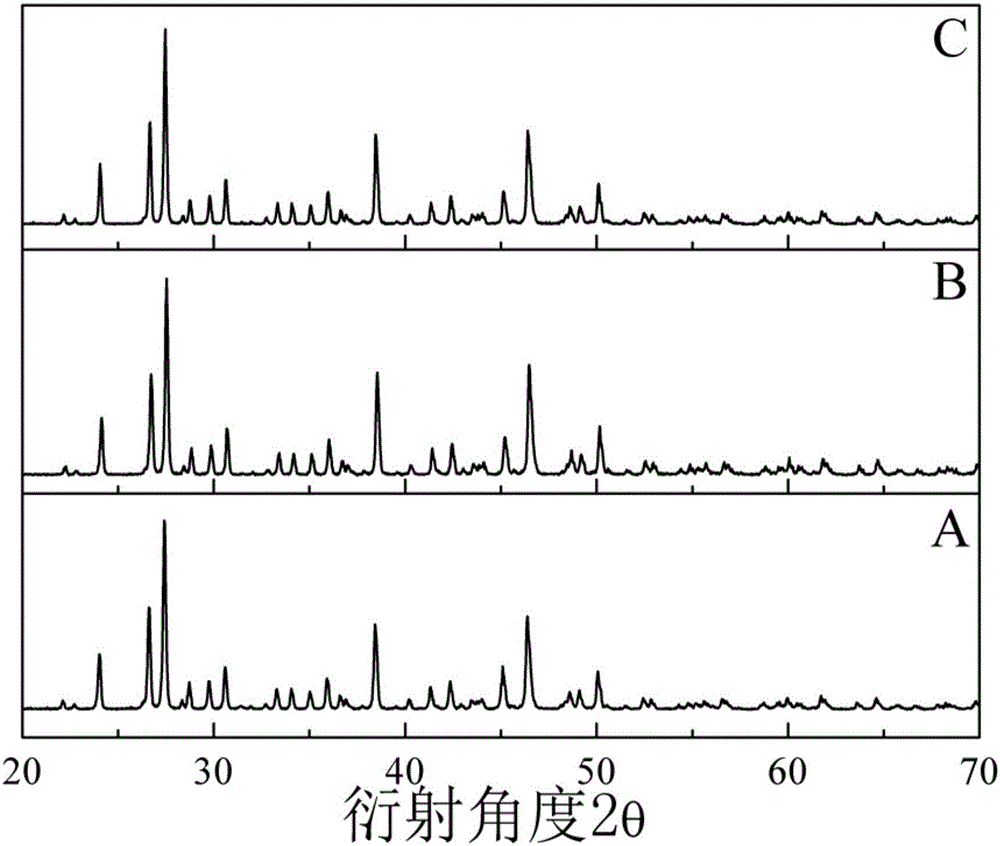

Embodiment 1

[0030] Weigh 1 g of CaIn 2 S 4 powder, added to a photocatalytic reactor containing 100 ml of deionized water, and then added 3.15 g of sodium sulfite Na 2 SO3 and 6 grams of sodium sulfide Na 2 S·9H 2 O, stir to make CaIn 2 S 4 The powder is fully suspended in the sulfide aqueous solution;

[0031] Add 310 µl of chloroauric acid HAuCl to the above suspension 4 aqueous solution (at a concentration of 40 g / L) and 160 µl of silver nitrate AgNO 3 Aqueous solution (concentration of 40 g / L), fully stirred for 10 minutes, and then sealed the photocatalytic reactor;

[0032] Nitrogen gas (flow rate: 50 ml / min) was introduced into the above-mentioned photocatalytic reactor for 45 minutes to exhaust the remaining air in the reactor, and then the light reaction under visible light was started for 2 hours. After the reaction, filter, wash and dry to obtain Au 0.6 Ag 0.4 / CaIn 2 S 4 Composite materials (where 0.6 refers to the loading of Au relative to CaIn 2 S 4 is 0.6 wt%,...

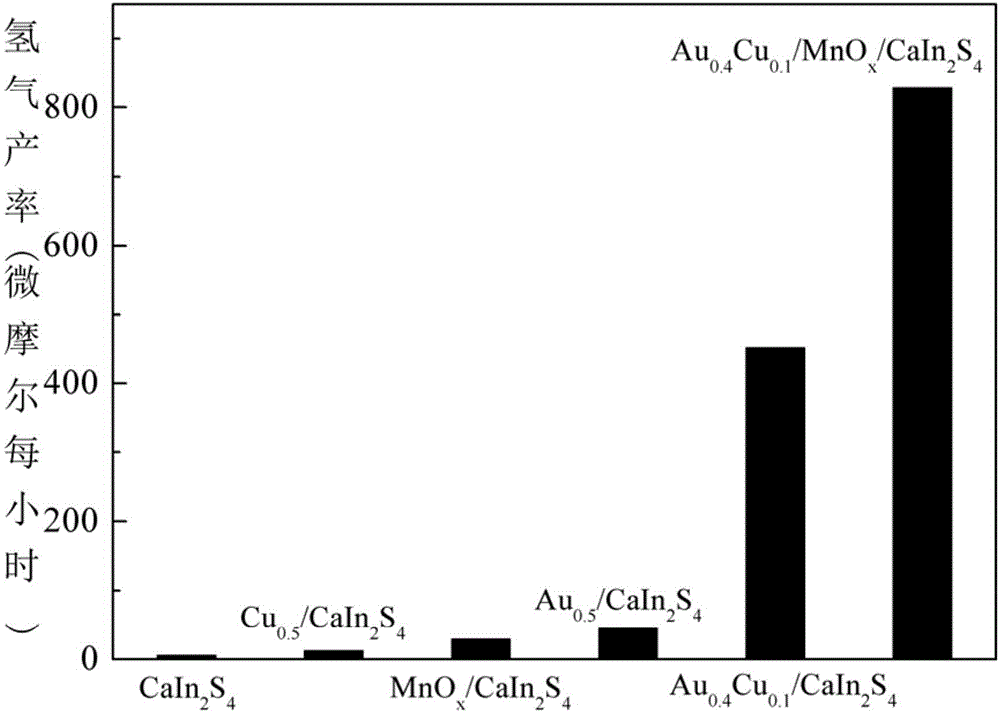

Embodiment 2

[0037] Weigh out 2 g of CaIn 2 S 4 powder, added to a photocatalytic reactor containing 150 ml of deionized water, and then 1.7 g of silver nitrate AgNO 3 , stirred for 20 minutes to obtain a uniform suspension;

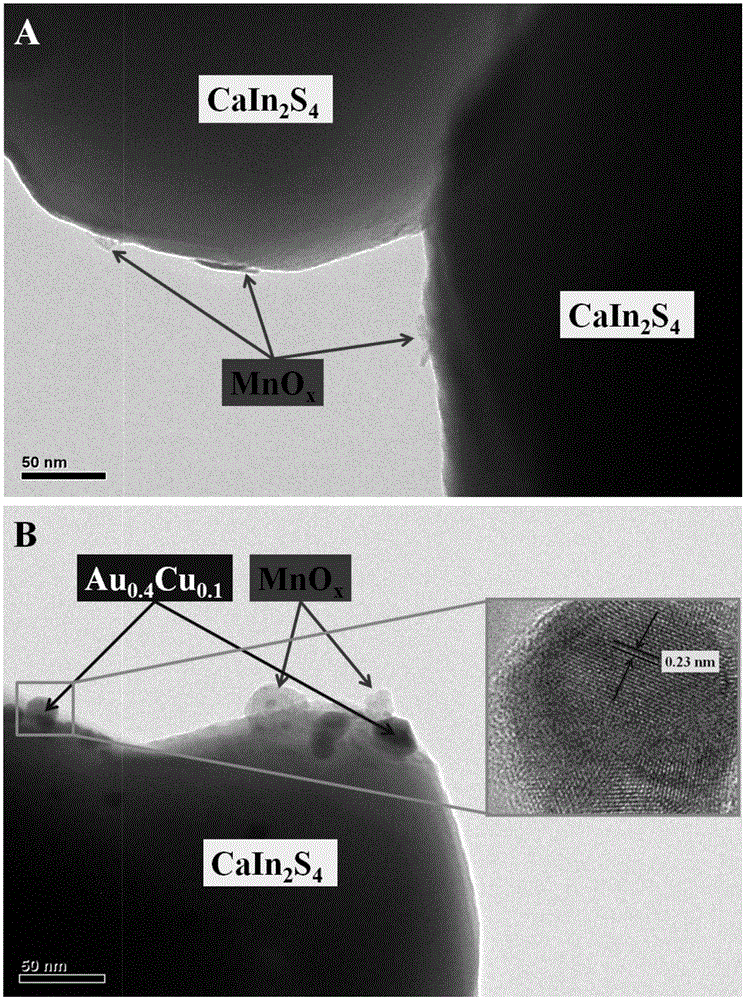

[0038] Add 210 microliters of manganese nitrate Mn(NO 3 ) 2 Aqueous solution (concentration: 40 g / L), fully stirred for 20 minutes, then sealed the photocatalytic reactor again and started light reaction for 4 hours. After the reaction is finished, filter, wash, and dry to obtain MnO x / CaIn 2 S 4 (the loading of MnOx is 0.1 wt%);

[0039] Weigh the MnO obtained above x / CaIn 2 S 4 150 mg, add 20 ml methanol, stir to make CaIn 2 S 4 The powder is fully suspended in methanol aqueous solution;

[0040] Add 32 µl of chloroauric acid HAuCl to the above suspension 4 aqueous solution (concentration of 40 g / L) and 14 μl copper nitrate Cu(NO 3 ) 2 Aqueous solution (concentration of 40 g / L), fully stirred for 15 minutes, and then sealed the photocatalytic rea...

Embodiment 3

[0048] Weigh out 0.5 g of CaIn 2 S 4 Powder, add in the photocatalytic reactor containing 80 milliliters of deionized water, then add 1.66 grams of potassium iodide KI, stir, make CaIn 2 S 4 The powder is fully suspended in KI aqueous solution;

[0049] Add 26 µl of chloroauric acid HAuCl to the above suspension 4 aqueous solution (concentration of 40 g / L) and 108 microliters of palladium nitrate Pd(NO 3 ) 2 Aqueous solution (concentration of 40 g / L), fully stirred for 30 minutes, and then sealed the photocatalytic reactor;

[0050] Introduce argon gas (flow rate 100 ml / min) into the photocatalytic reactor for 20 minutes to exhaust the remaining air in the reactor, and then start to react under visible light for 4 hours. After the reaction, filter, wash and dry to obtain Au 0.4 PD 1.6 / CaIn 2 S 4 Composite materials (where 0.4 refers to the loading of Au relative to CaIn 2 S 4 is 0.4 wt%, 1.6 refers to the loading of Pd relative to CaIn 2 S 4 is 1.6 wt%);

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com