Modified nitrile hydratase and application thereof

A nitrile hydratase and amino acid technology, applied in the application, enzyme, lyase and other directions, can solve the problems of fluctuation of hydration temperature, insufficient supply of cold energy for temperature control, poor heat resistance of enzyme-producing cells, etc., to improve product tolerance , the effect of improving heat resistance and good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Nitrile hydratase SBMDB gene replacement process after transformation

[0033] (1) Using the plasmid pNV-SBM (Chen Jie et al., Catalytic Kinetics of Recombinant Nitrile Hydratase Coupled with Terminal Salt Bridge and Site-directed Mutation. Acta Chemical and Chemical Industry, 2014, 65(7): 2821-2828) as template, reverse polymerization Enzyme chain reaction (PCR) method for gene mutation. The substitution Aspβ215Cys was first introduced to the β subunit of the nitrile hydratase SBM.

[0034] Forward primer SBM-beta215-sense: TGTGTAGTGTGCGTCGATCTCTG; reverse primer SBM-beta215-anti: TTTCCCGTTTCCGTCGTCG.

[0035] The PCR reaction system is:

[0036]

[0037]

[0038] The reaction conditions are:

[0039]

[0040] The obtained PCR amplification products were recovered using the E.Z.N.A.Gel Extraction Kit produced by OMEGA Biotek, and the recovery process was completed according to the process described in the instructions. The obtained DNA fragme...

Embodiment 2

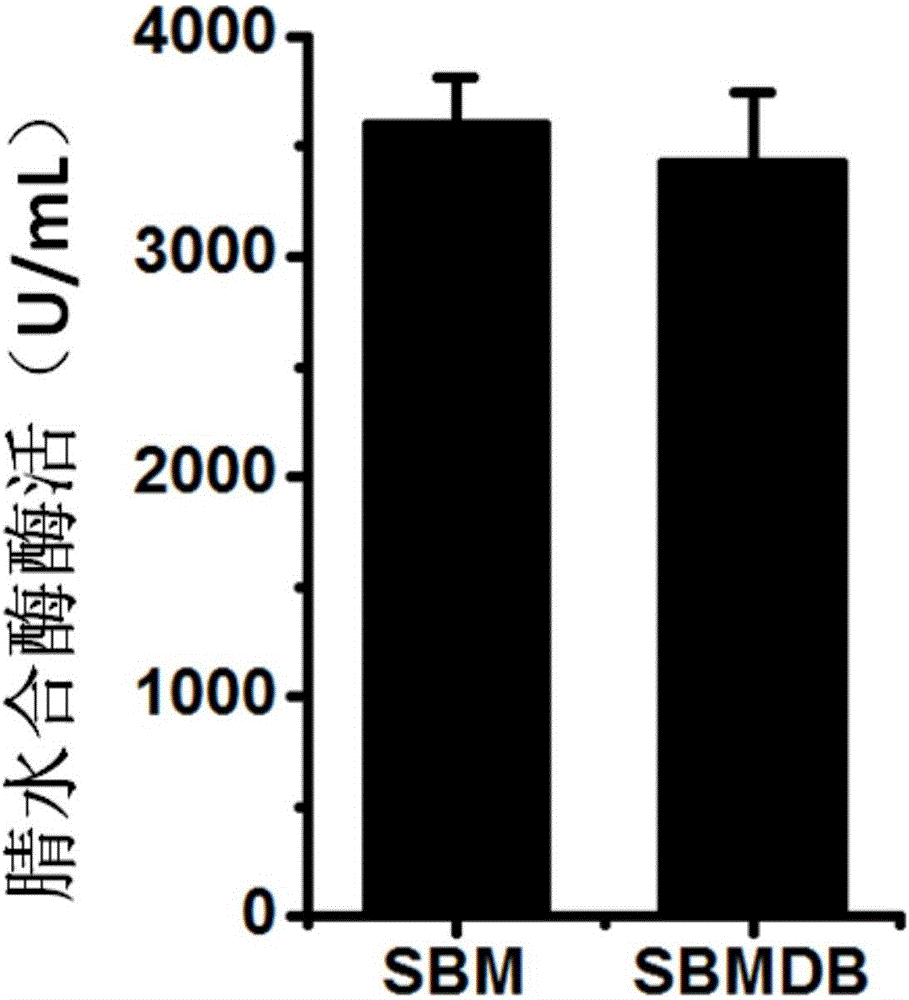

[0047] Example 2: Construction of transformed nitrile hydratase transformants and expression of transformed nitrile hydratase in transformants

[0048] The plasmid PNV-SBMDB of the modified nitrile hydratase gene (shown in SEQ ID NO: 3) obtained in Example 1 was transferred into the host bacterium Rhodococcus ruber R. ruber TH3 by electroporation. The transformant was screened with a rhodococcus plate medium containing 25 mg / L of kanamycin to obtain the transformant R.ruber TH3 / pNV-SBMDB.

[0049] The obtained expression strain R.ruberTH3 / pNV-SBMDB was cultured by shake flask fermentation. First inoculate in Rhodococcus seed culture medium containing 25mg / L kanamycin, and culture at 28°C and 200rpm for 36h.

[0050] Inoculate 10% of the cultured seed liquid into the Rhodococcus fermentation medium, and cultivate at 28° C. and 200 rpm for 48 hours. The resulting cells were assayed for enzyme activity.

[0051] The composition of Rhodococcus plate medium is: glucose 10g / L, ye...

Embodiment 3

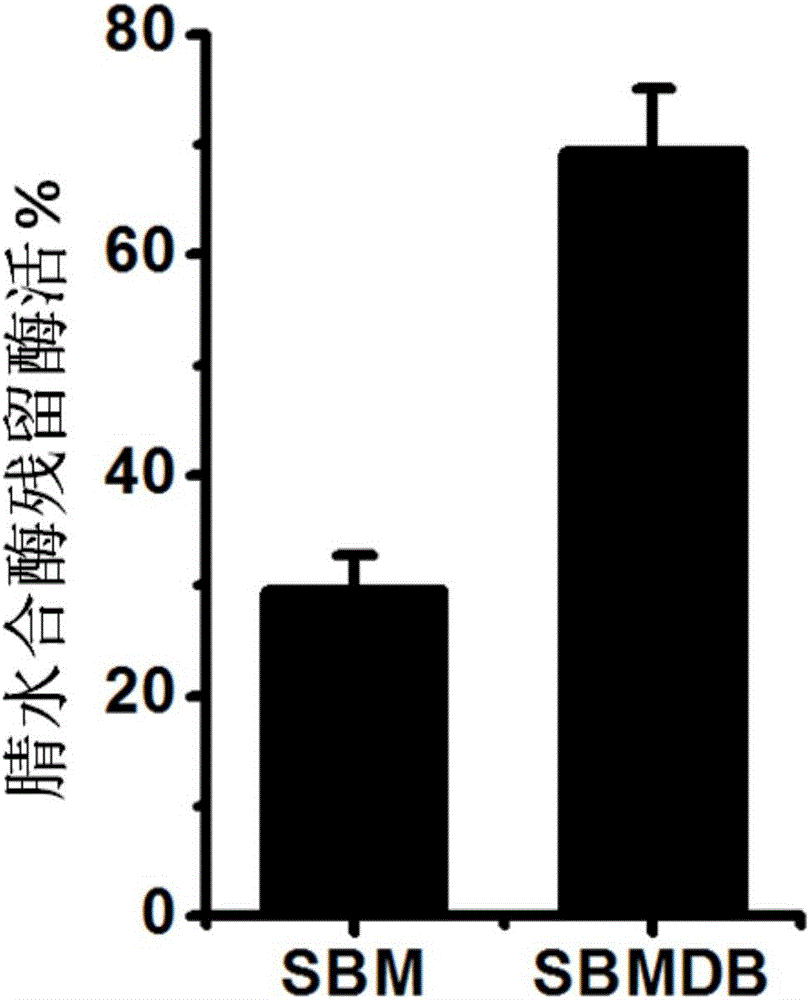

[0056] Embodiment 3: the stress resistance assessment of nitrile hydratase after transformation

[0057] The 50mL expression bacterial strain R.ruber TH3 / pNV-SBMDB cell (expression transforming nitrile hydratase) and the control bacterial strain R.ruber TH3 / pNV-SBM cell of harvest in embodiment 2 are washed once with deionized water of equal volume, again Suspend in an equal volume of 10 mM PBS buffer.

[0058] Take 5 mL of the resuspended cells and place them in a water bath at 60°C for 10 min. The residual enzyme activity of modified nitrile hydratase and unmodified nitrile hydratase was measured, and the results showed that the residual enzyme activity of modified nitrile hydratase was 69.40%, while that of unmodified nitrile hydratase was only 29.47%. The thermostability of the modified nitrile hydratase was significantly improved (such as figure 2 ).

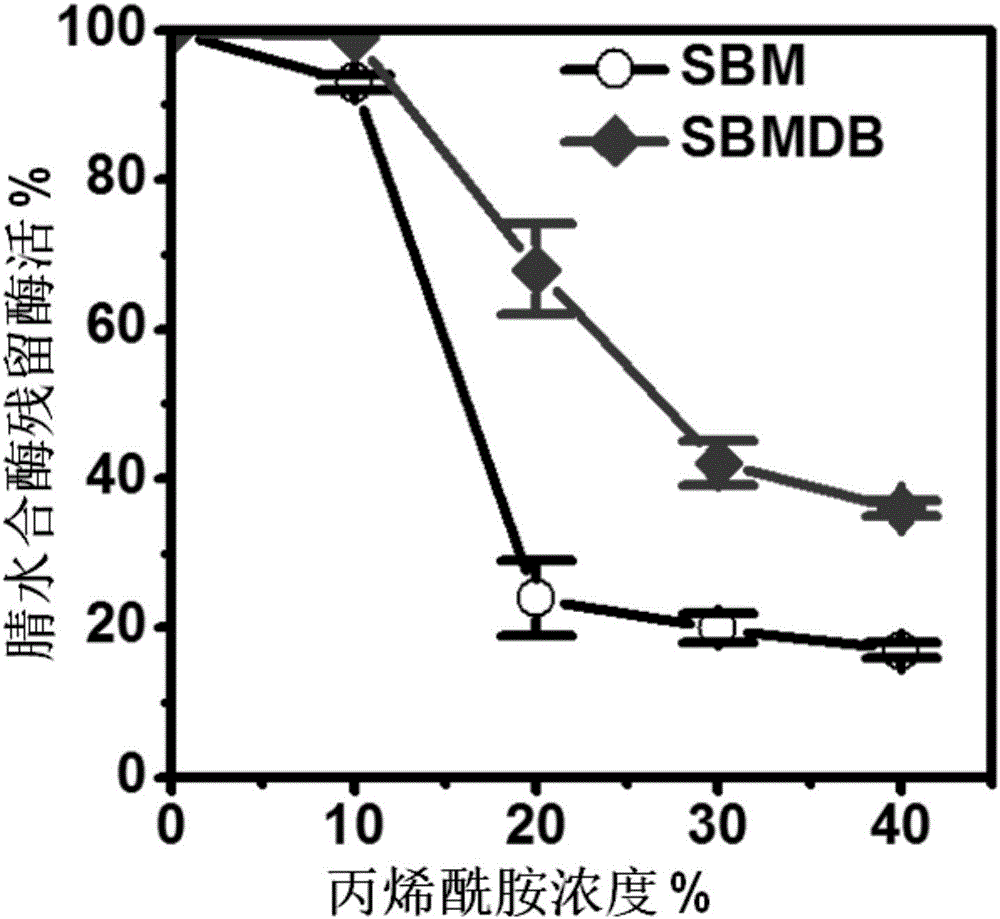

[0059] 20 mL of resuspended recombinant cells were placed in 100 mL Erlenmeyer flasks, and acrylamide was added dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com