A method for promoting drying and dehydration of potato dregs and its application

A potato dregs and fermentation method technology, applied in the application, bacteria used in food preparation, food processing and other directions, can solve the problems of potato dregs transformation and utilization and efficiency improvement, enterprise trouble and loss, easy accumulation and corruption, etc. problems, to achieve the effect of enhancing the ability to inhibit corruption, improving application value, and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 1U / g of pectinase to fresh potato residue, and inoculate the concentration of 5.6×10 9 CFU / mL Lactobacillus plantarum CCTCC M 2017138 bacterial liquid, the inoculation amount is 10% (bacterial liquid volume mL / fermentation substrate mass g), after mixing evenly, solid-state anaerobic fermentation at 37°C for 72h. Centrifuge and dehydrate after fermentation, measure the total number of colonies in the fermentation system, and take out a certain amount of potato dregs to observe the mildew at room temperature. Fresh potato pomace was used as a control and cultured under the same conditions (solid-state anaerobic fermentation at 37°C for 72h).

[0034] As shown in Table 1 of the measurement results, the addition of pectinase and Lactobacillus plantarum fermentation treatment can significantly reduce the total number of colonies in the fresh potato residue system, and the total number of colonies is from 2.20×10 8 Reduced to 3.46×10 7 (at least an order of magnitude)....

Embodiment 2

[0039] Add the following substances to the fresh potato residues respectively:

[0040] (1) Pectinase and cellulase mixed enzyme solution with a mixing ratio of 1:4 (enzyme activity ratio); (2) pectinase and cellulase at a mixing ratio of 1:2:3 (enzyme activity ratio) Mix the enzyme solution with hemicellulase, the amount of pectinase added is 0.25U / g; (3) the mixing ratio of pectinase and cellulase is 1:1 (enzyme activity ratio), the amount of pectinase added is 3.75 U / g; (4) The amount of pectinase added is 0.25U / g.

[0041] (2) After mixing the above-mentioned enzyme liquid and fresh potato dregs evenly, the concentration of inoculated bacteria liquid was 4.40×10 9 CFU / mL of Lactobacillus plantarum CCFM 8661 bacterial liquid, the inoculum amount is 4% (bacterial liquid volume mL / fermentation substrate mass g), after mixing evenly, spread it flat, seal the bag or seal it with a film. Solid state anaerobic fermentation at 37°C for 72 hours. After the fermentation, it was d...

Embodiment 3

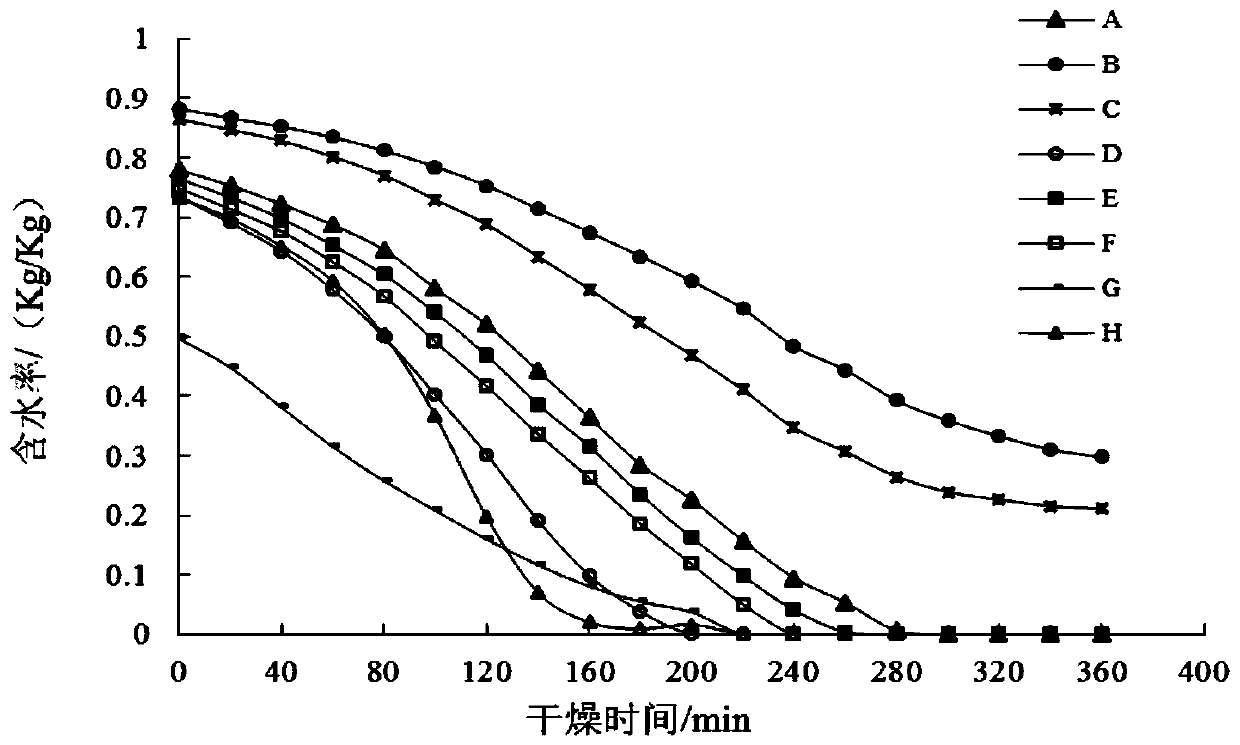

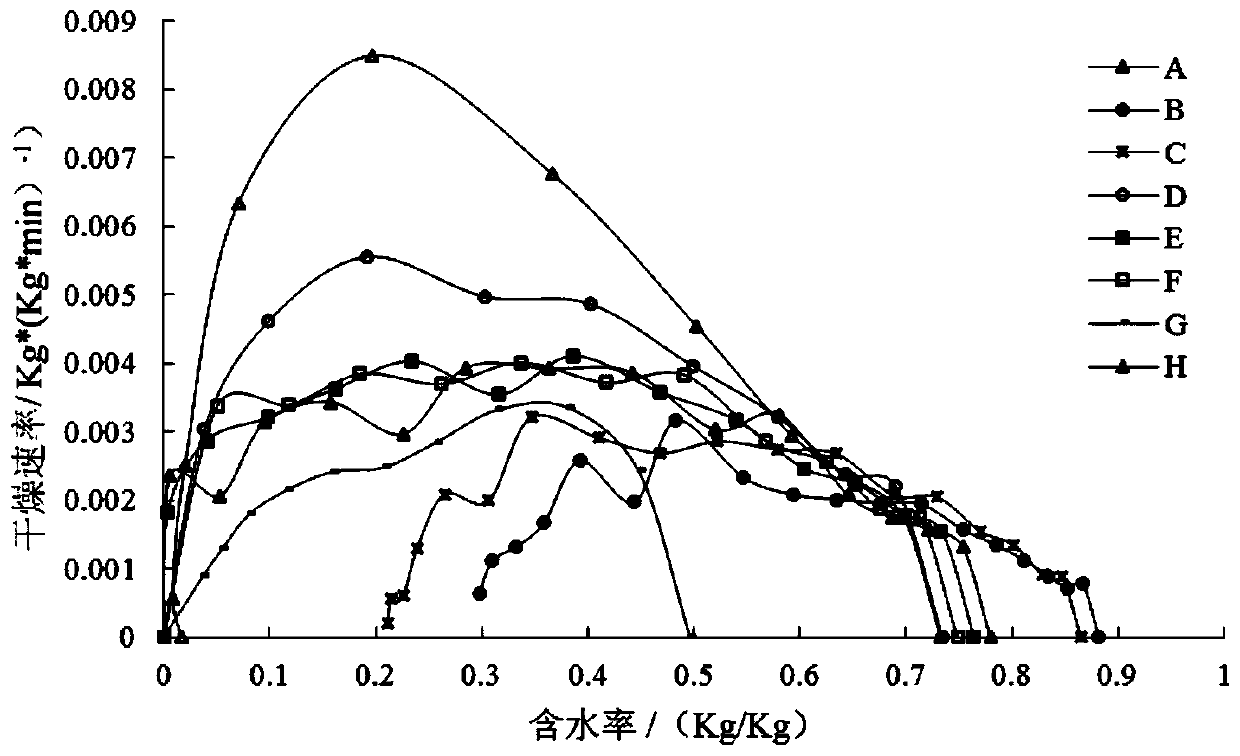

[0044] Add pectinase and cellulase with a mixing ratio of 1:4 to the fresh potato residue, and the pectinase addition amount is 0.25U / g, mix evenly, inoculate the mixed bacterial liquid of Lactobacillus plantarum and highly active yeast, and inoculate The amount is 6%, and the bacterial concentration of Lactobacillus plantarum (CCFM 8661) is 3.2×10 9 CFU / mL, the rehydration ratio of highly active yeast is 40:1 (water quality: yeast powder quality), and the viable count of high active yeast is 7.9×10 7 CFU / mL, the mixing ratio of the two strains is 1:2 (volume ratio), after mixing evenly, spread it flat, seal the bag or seal it with a film. Solid state anaerobic fermentation at 37°C for 48h. After the fermentation, the samples were centrifuged and dehydrated, and then air-dried at 55°C. Record the drying time of the sample, the moisture content at the drying end point, and the yield after drying. The result is as figure 2 shown.

[0045] The fresh potato dregs (wet dregs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com