Surface immobilized modified cornea repair material and preparation method thereof

A technology for repairing materials and corneas, which is applied in medical science, prostheses, tissue regeneration, etc. It can solve the problems of poor mechanical properties, light transmission, oxygen permeability, and film-forming properties, and cannot meet the clinical needs of corneal repair materials. Good physical and chemical properties, large-scale mass production, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

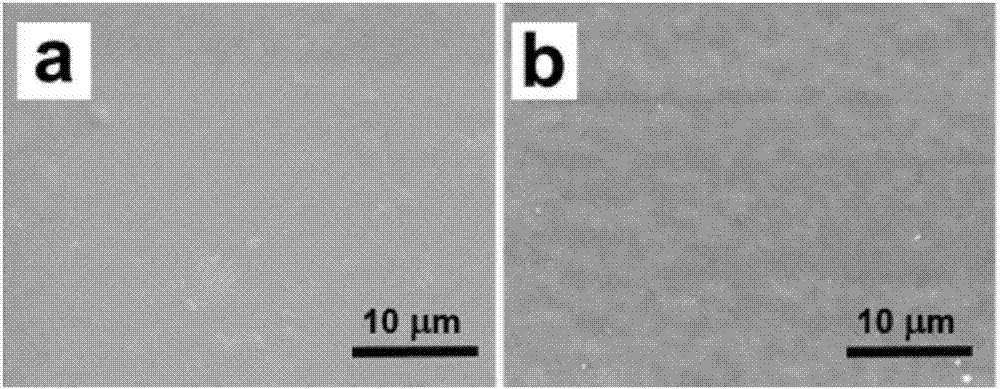

[0024] Dissolve gelatin in 0% acetic acid solution, stir mechanically at 60°C for 1 hour (stirring speed is 700r / min), prepare a gelatin solution with a weight ratio of 20wt%, then inject the gelatin solution into a mold, and dry it naturally at room temperature Get gelatin film for later use. Get chitosan and cross-linking agent EDC / NHS (mass ratio cross-linking agent / chitosan=1 / 700) and dissolve in 5% hydrochloric acid solution, under the condition of 25 ℃ mechanical stirring 24h (stirring speed is 100r / min) , preparing a chitosan mixed solution with a weight ratio of 3wt%, soaking the prepared gelatin film in the chitosan mixed solution for 2 hours, taking it out at room temperature and drying it naturally to obtain a surface-immobilized modified gelatin corneal repair material. After immobilization and modification, the roughness of the membrane surface is significantly improved, which is more conducive to cell adhesion and growth. figure 1 Shown are the microscopic topog...

Embodiment 2

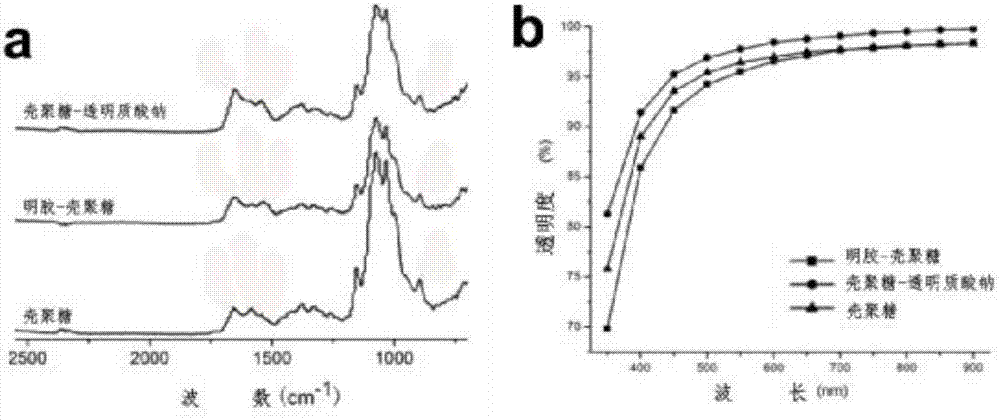

[0026] Get chitosan and be dissolved in 0.5% hydrochloric acid solution, under the condition of 50 ℃ of mechanical stirring 8h (stirring speed is 500r / min), preparation weight ratio is the chitosan solution of 5wt%, then chitosan solution is injected in the mould. , dried naturally at room temperature to prepare chitosan film for later use. Sodium hyaluronate and cross-linking agent glutaraldehyde (mass ratio cross-linking agent / sodium hyaluronate=1 / 100) were dissolved in 1% acetic acid solution, and mechanically stirred for 36 hours at 10°C (stirring rate was 100r / min), prepare a sodium hyaluronate mixed solution with a weight ratio of 15wt%; soak the prepared chitosan film in the sodium hyaluronate mixed solution for 1 hour, take it out and dry it under vacuum at 30°C to obtain the surface-immobilized modified shell Polysaccharide corneal repair material. A single polymer film is immobilized and modified, which can effectively improve the transparency of corneal repair mat...

Embodiment 3

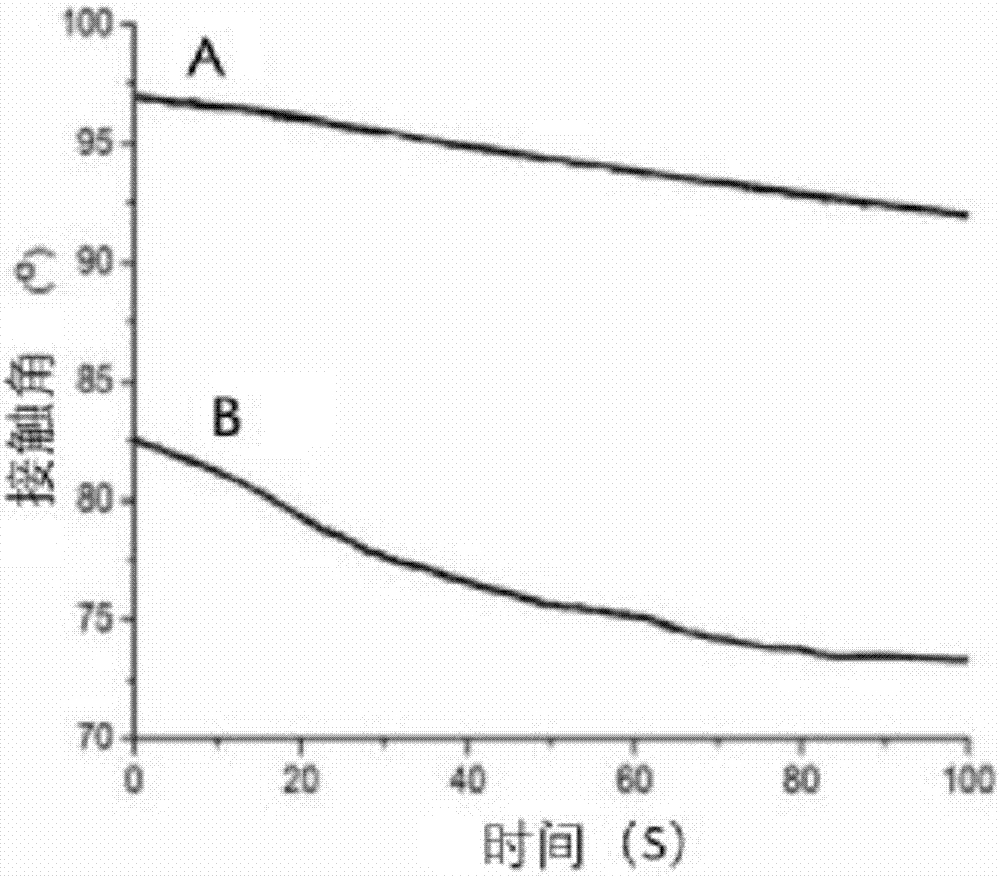

[0028] Dissolve collagen in 5% hydrochloric acid solution, stir mechanically at 10°C for 36h (stirring rate is 100r / min), prepare a collagen solution with a weight ratio of 1wt%, then inject the collagen solution into a mold, and dry it naturally at room temperature. Get the collagen film for later use. Sodium hyaluronate and cross-linking agent EDC / NHS (mass ratio cross-linking agent / sodium hyaluronate=1 / 1000) were dissolved in 1.5% hydrochloric acid solution, and mechanically stirred for 18 hours at 30°C (stirring speed was 200r / min), prepare a sodium hyaluronate mixed solution with a weight ratio of 1 wt%; soak the prepared gelatin film in the sodium hyaluronate mixed solution for 36 hours, take it out and dry it under vacuum at 50°C to obtain the surface-immobilized modified collagen corneal repair Material. After the gelatin film is immobilized and modified, the contact angle decreases, indicating that its surface hydrophilicity is enhanced, which is more conducive to k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com