Novel liquid embolization material and preparing method thereof

A liquid and embolization technology, used in medical science, surgery, etc., can solve the problems of "sticky tubes, inability to tightly adhere to the walls of diseased blood vessels, etc., and achieve the effects of increasing density, dense embolization, and improving development efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

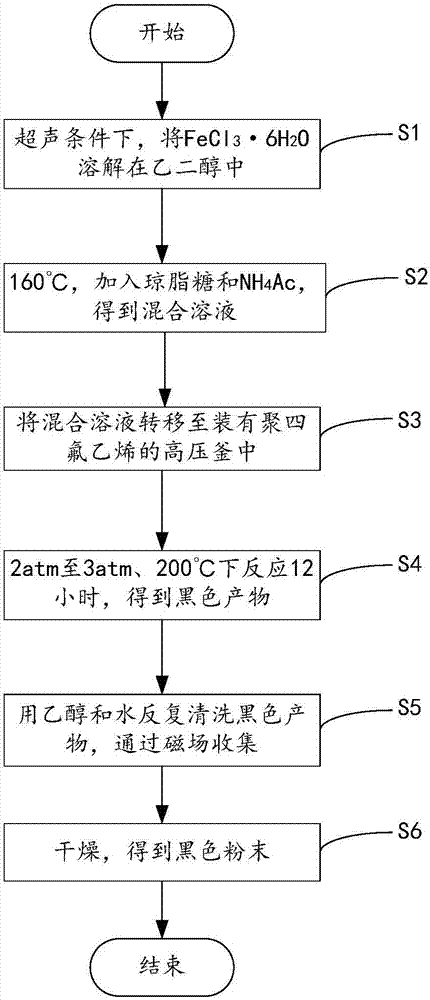

[0029] agarose-coated Fe 3 o 4 Methods for the preparation of nanoparticles.

[0030] see figure 2 , figure 2 is agarose-coated Fe 3 o 4 Flowchart of the preparation of nanoparticles. First execute step S1, 400 grams of FeCl 3 ·6H 2 O was dissolved in a glass reaction vial containing 2 L of ethylene glycol under ultrasonic conditions; then step S2 was performed, and 40 g of agarose and 200 g of NH were added thereto at a temperature of 160 °C 4 Ac, stir for 1 hour to obtain a mixed solution; then perform step S3, transfer the mixed solution to an autoclave equipped with polytetrafluoroethylene; further perform step S4, at 2atm (standard atmospheric pressure) to 3atm, 200 ° C temperature conditions React for 12 hours; cool to room temperature after the reaction to obtain a black product; then perform step S5, repeatedly wash the black product with ethanol and water several times, then collect the black product through a magnetic field; finally perform step S6, and col...

Embodiment 1

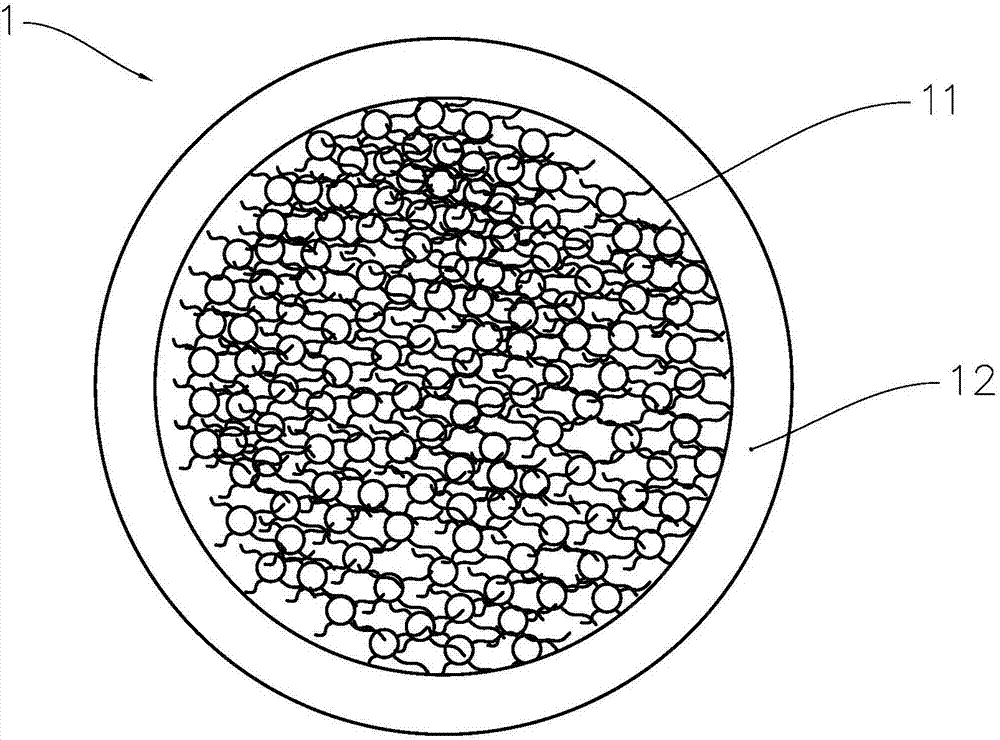

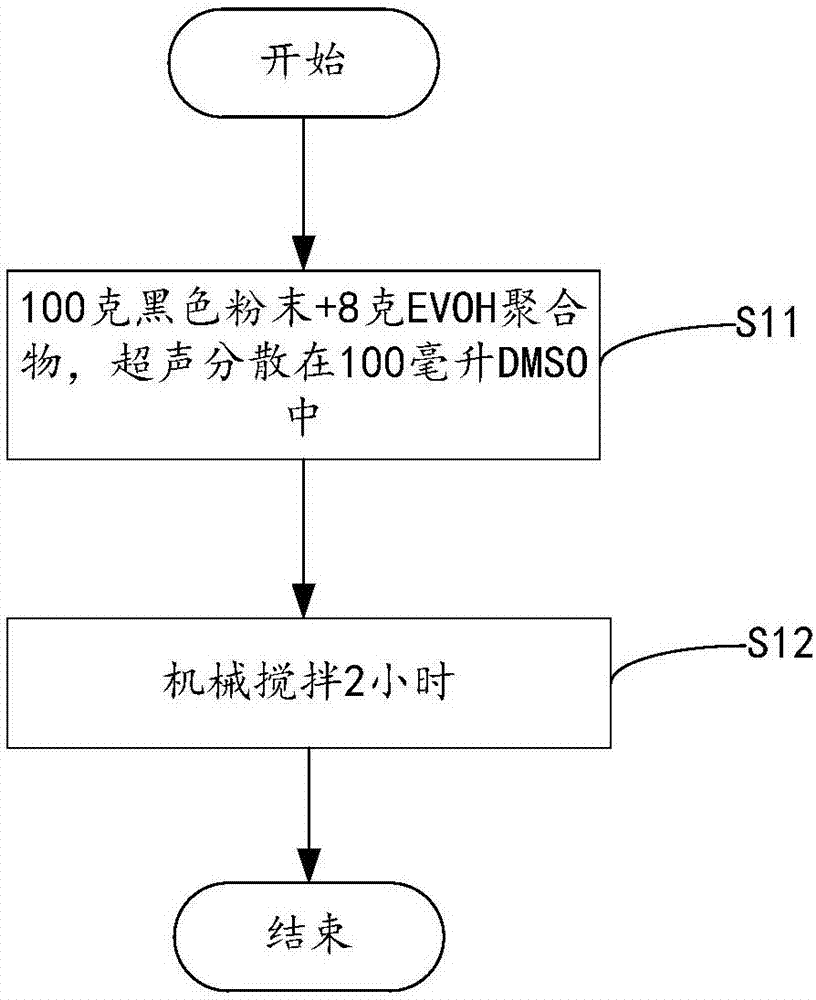

[0032] see image 3 , image 3 It is the preparation flowchart of the liquid embolism material of embodiment one. First perform step S11, take 100 grams of the above-mentioned black powder and 8 grams of EVOH polymer and disperse them in 100 ml of dimethyl sulfoxide solvent under ultrasonic conditions; then perform step S12, mechanically stir for 2 hours to obtain a liquid embolism material, the Liquid embolization material contains a large amount of Fe encapsulated in agarose 3 o 4 Nano-composite particles with nanoparticles as the core and EVOH polymer as the shell. This liquid embolic material is low viscous, with a viscosity value around 30 centipoise.

[0033] see Figure 4 , Figure 4 It is a schematic diagram of the embolization of the liquid embolic material in the AVM of this embodiment. In this embodiment, after the liquid embolic material 100 is injected into the arteries of the AVM 100 through the microcatheter 110, due to the low viscosity and strong penetr...

Embodiment 2

[0035] see Figure 5 , Figure 5 It is the preparation flowchart of the liquid embolic material of embodiment two. First perform step S21, take 100 grams of the above-mentioned black powder and 20 grams of EVOH polymer and disperse them in 100 ml of dimethyl sulfoxide solvent under ultrasonic conditions; then perform step S22, mechanically stir for 2 hours to obtain a liquid embolism material, the Liquid embolization material contains a large amount of Fe encapsulated in agarose 3 o 4 Nano-composite particles with nanoparticles as the core and EVOH polymer as the shell. This liquid embolic material is highly viscous, with a viscosity value of up to 1000 centipoise.

[0036] see Image 6 , Image 6 It is a schematic diagram of the embolization of the liquid embolism material in the cerebral aneurysm in this embodiment. In this embodiment, the liquid embolic material 200 is injected into the position of the cerebral aneurysm 240 from the blood vessel 230 through the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com