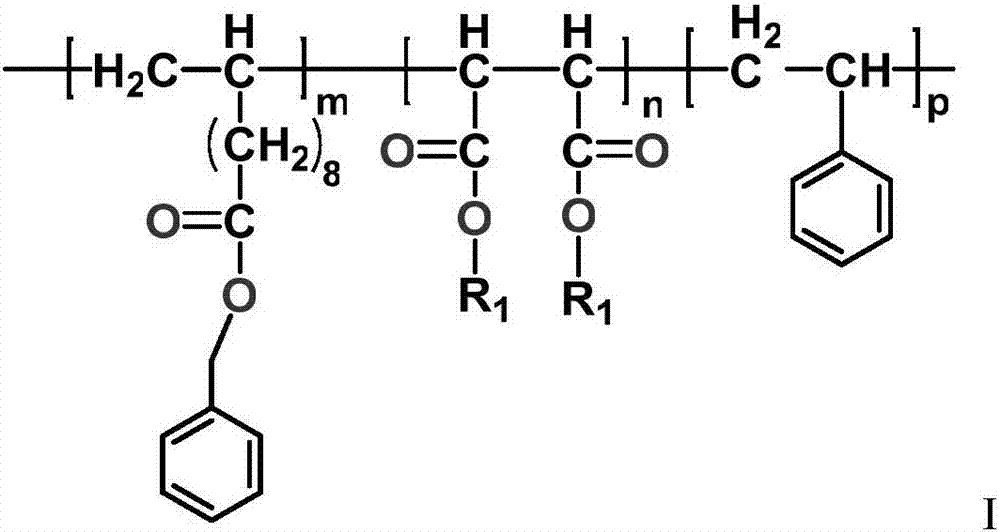

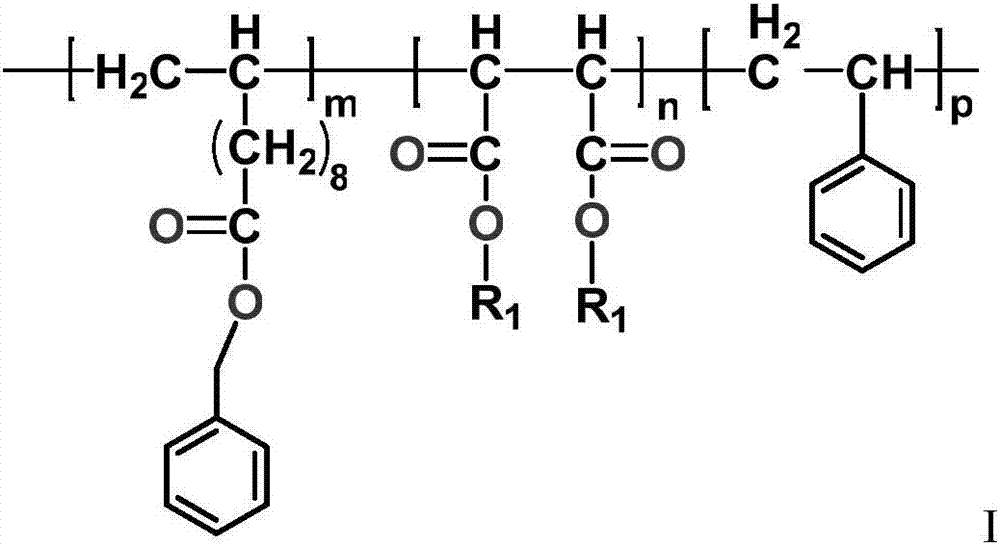

Poly-aromatic alcoholysis-type ternary polymer diesel pour point reducer and preparation method thereof

A ternary polymer, diesel pour point depressant technology, used in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problem of pour point depressant without filtration, paraffin-based diesel without filtration effect or no filtration effect. Reverse rise, poor universality and other problems, to achieve the effect of reducing the freezing point, enhancing the dispersion effect, and easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add 10.8g (0.1mol) of benzyl alcohol, 24.0g (0.13mol) of ten Alkenoic acid, 0.42g p-toluenesulfonic acid, 0.31g hydroquinone, 50ml solvent toluene, heat up to 110°C, stir and reflux for 5h. After the reaction is over, pour the reaction mixture into a round-bottomed flask, and use a rotary evaporator for rotary evaporation to remove the solvent toluene, then wash with saturated sodium carbonate solution and saturated saline until the water layer is colorless, and then wash with distilled water Repeated washing several times until the water layer is neutral, after separation, wash with anhydrous MgSO 4 After drying and filtering, benzyl undecylenate was obtained as a brown-yellow oily liquid.

[0025] (2) Add 2.74g (0.01mol) benzyl undecylenate, 0.49g (0.01 mol) maleic anhydride, 2.08g (0.02mol) styrene, and 20ml toluene. At the same time, the three-necked flask was ventilated with nitrogen for 4 to 5 minutes, then vacuumed for about 1 to 2 minutes, and repeated 3 t...

Embodiment 2

[0027] The difference with Example 1 is that step (2): add 2.74g (0.01mol) decant successively to the reaction flask equipped with electric stirrer, temperature controller, constant pressure dropping funnel, reflux condenser and nitrogen inlet tube Benzyl monoenoate, 0.98g (0.02mol) maleic anhydride, 2.08g (0.02mol) styrene, 20ml toluene, and at the same time, pass nitrogen gas through the three-necked flask for 4-5 minutes, then vacuumize for about 1-2 minutes, repeat 3 times, to remove air from the reaction system. When the reaction temperature reaches 80°C, slowly dropwise add 0.07g of benzoyl peroxide dissolved in toluene solution (30-45min) and stir and reflux for 6h. After 6 hours of polymerization reaction, 8.58 g (0.04 mol) of tetradecyl alcohol, 0.29 g of catalyst p-toluenesulfonic acid, and 20 ml of toluene were added to the reaction system, and the reaction was carried out at a temperature of 115° C. for 7 hours. After the reaction solution was cooled to room tempe...

Embodiment 3

[0029]The difference with Example 1 is that step (2): add 2.74g (0.01mol) decant successively to the reaction flask equipped with electric stirrer, temperature controller, constant pressure dropping funnel, reflux condenser and nitrogen inlet tube Benzyl monoenoate, 1.47g (0.03mol) maleic anhydride, 2.08g (0.02mol) styrene, 20ml toluene, and at the same time, pass nitrogen gas through the three-necked flask for 4-5 minutes, then vacuumize for about 1-2 minutes, repeat 3 times, to remove air from the reaction system. When the reaction temperature reaches 80°C, slowly dropwise add 0.075g of benzoyl peroxide dissolved in toluene solution (30-45min to complete the addition), and stir to reflux for 6h. After 6 hours of polymerization reaction, 12.86 g (0.06 mol) of tetradecyl alcohol, 0.383 g of catalyst p-toluenesulfonic acid, and 30 ml of toluene were added to the reaction system, and the reaction was carried out at a temperature of 115° C. for 7 hours. After the reaction soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com