Electro-spinning jet directional coating device and process for preparing polymer tube through directional coating device

A coating device and polymer technology, applied in the field of medical biomaterials and tissue engineering, can solve the problems of uneven thickness of pipes, difficult to control dimensions such as inner diameter and wall thickness, and the degree of orientation needs to be improved, and achieve uniform thickness, thickness and The effect of precise control of specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

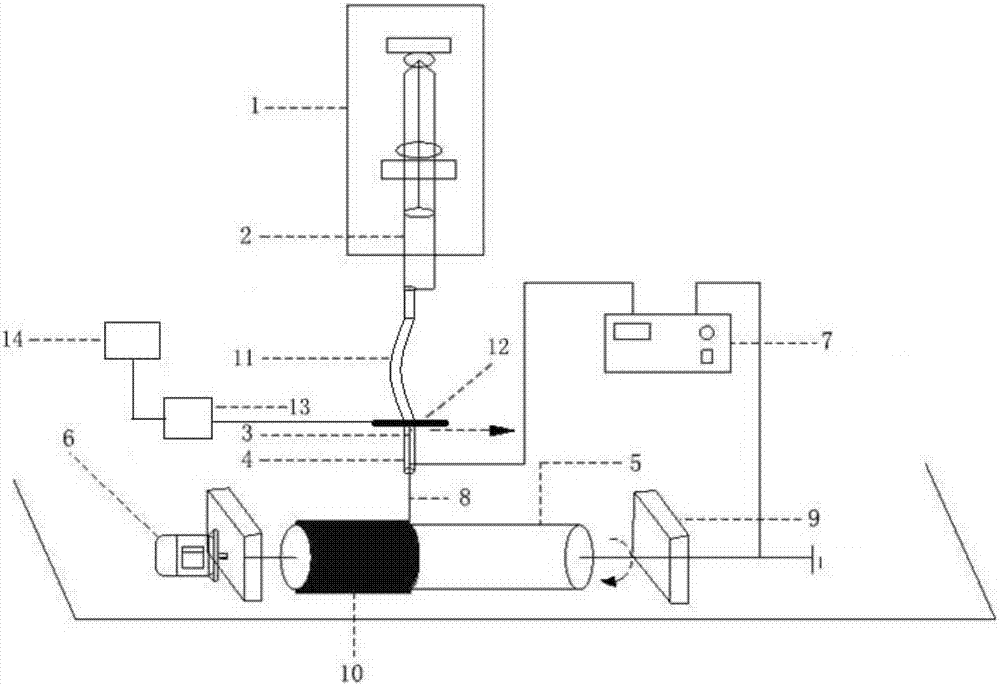

[0045] An electrospinning jet directional coating device, such as figure 1 As shown, it includes: a micro-injection pump 1, a metal receiving device and a high-voltage power supply 7; the micro-injection pump 1 is connected to a syringe 2, and the syringe 2 is connected to a metal jet nozzle 3 through a polytetrafluoroethylene tube 11, and the periphery of the metal jet nozzle 3 is An electric field shielding tube 4 is provided, and the metal jet nozzle 3 and the electric field shielding tube 4 are all connected to the same electrode of the high-voltage power supply 7 through wires; the vertical distance between the metal receiving device and the tip of the metal jet nozzle 3 is smaller than where the jet 8 whips and The vertical distance of the tip of the metal jet nozzle 3, the metal receiving device is connected with the ground wire of the high voltage power supply 7.

[0046] The metal receiving device includes a metal receiving rod 5, a mounting plate 9 and a motor 6; bot...

Embodiment 2

[0053] Utilize the technique that the electrospinning jet directional coating device described in embodiment 1 prepares L-polylactic acid (PLLA) tubing, comprise steps as follows:

[0054] (1) Configuration of the polymer solution: Weigh 15 g of L-polylactic acid with a viscosity-average molecular weight of 300K, dissolve it in 100 mL of trifluoroethanol, and stir magnetically at room temperature for 12 hours to obtain a uniform and transparent polymer solution;

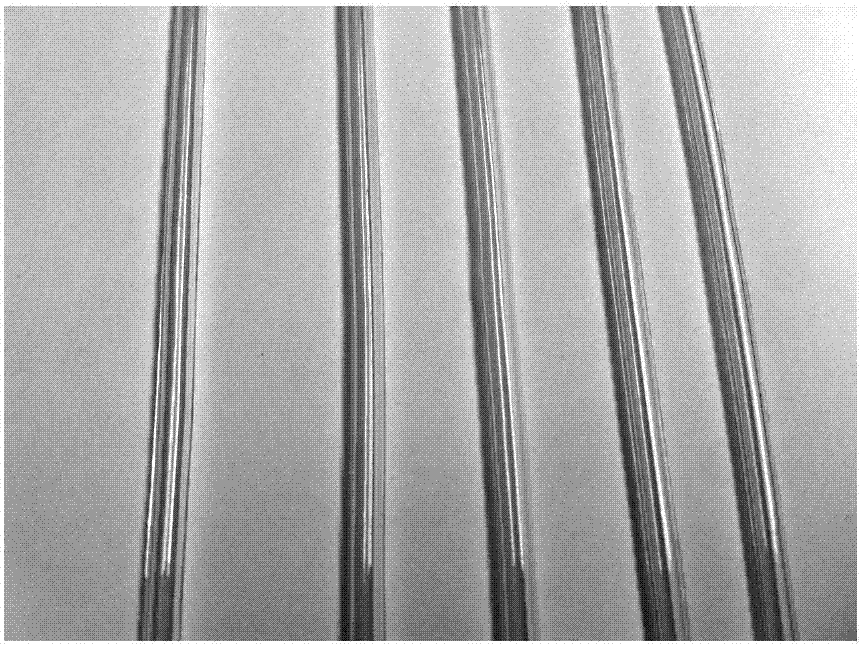

[0055] (2) Preparation of L-polylactic acid (PLLA) tubing: Add 60 mL of the polymer solution obtained in step (1) into a 60 mL syringe 2, adjust the propulsion rate of the micro-injection pump 1 to 15 mL / h, and set the voltage of the high-voltage power supply 7 to 15 mL / h. 15KV, the metal jet nozzle 3 and the electric field shielding tube 4 are charged with the same polarity, the vertical distance between the tip of the metal jet nozzle 3 and the metal receiving rod 5 (4mm in diameter, 30cm in length) is adjusted to b...

Embodiment 3

[0059] Utilize the technique that the electrospinning jet directional coating device described in embodiment 1 prepares L-polylactic acid (PLLA) tubing, comprise steps as follows:

[0060] (1) Configuration of the polymer solution: Weigh 15 g of L-polylactic acid with a viscosity-average molecular weight of 300K, dissolve it in 100 mL of trifluoroethanol, and stir magnetically at room temperature for 12 hours to obtain a uniform and transparent polymer solution;

[0061] (2) Preparation of racemic polylactic acid (PDLA) tubing: add 60 mL of the polymer solution obtained in step (1) into a 60 mL syringe 2, adjust the propulsion rate of the micro-injection pump 1 to 10 mL / h, and the voltage of the high-voltage power supply 7 Be set as 13KV, make the metal jet nozzle 3 and the electric field shielding tube 4 have the charge of the same polarity, adjust the vertical distance between the tip of the metal jet nozzle 3 and the metal receiving rod 5 (diameter 4mm, length is 30cm) to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com