Natural high-polymer bioactive trauma repair material with function of releasing active ions and method for preparing natural high-polymer bioactive trauma repair material

A technology of polymer biology and natural polymer, applied in the field of biomedical materials, can solve problems such as difficult to use patch materials, failure to enter the composite phase, and damage to the structure of the polymer matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of calcium silicate leaching solution:

[0064] The original solution of CS extract was diluted 64, 16, and 4 times with cell culture medium, shaken evenly at room temperature, and then sterilized through a 0.22mm filter, and stored in a refrigerator at 4°C for future use.

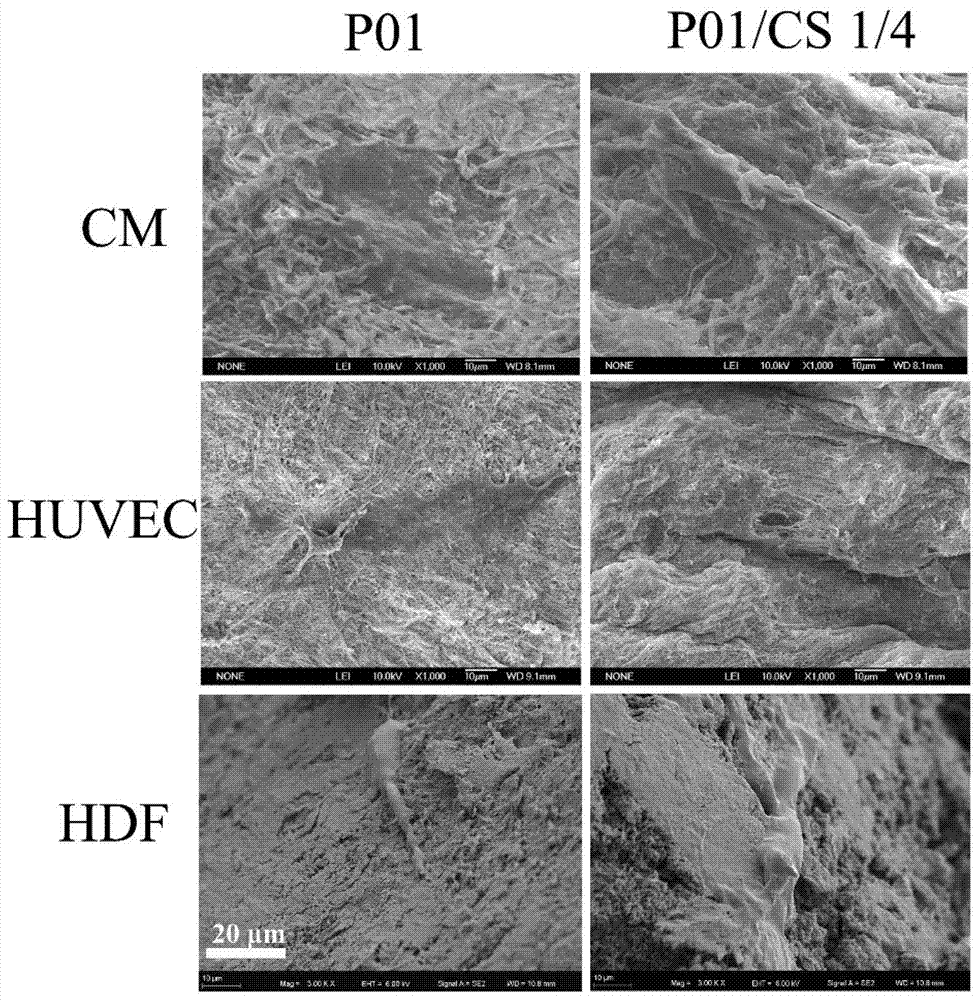

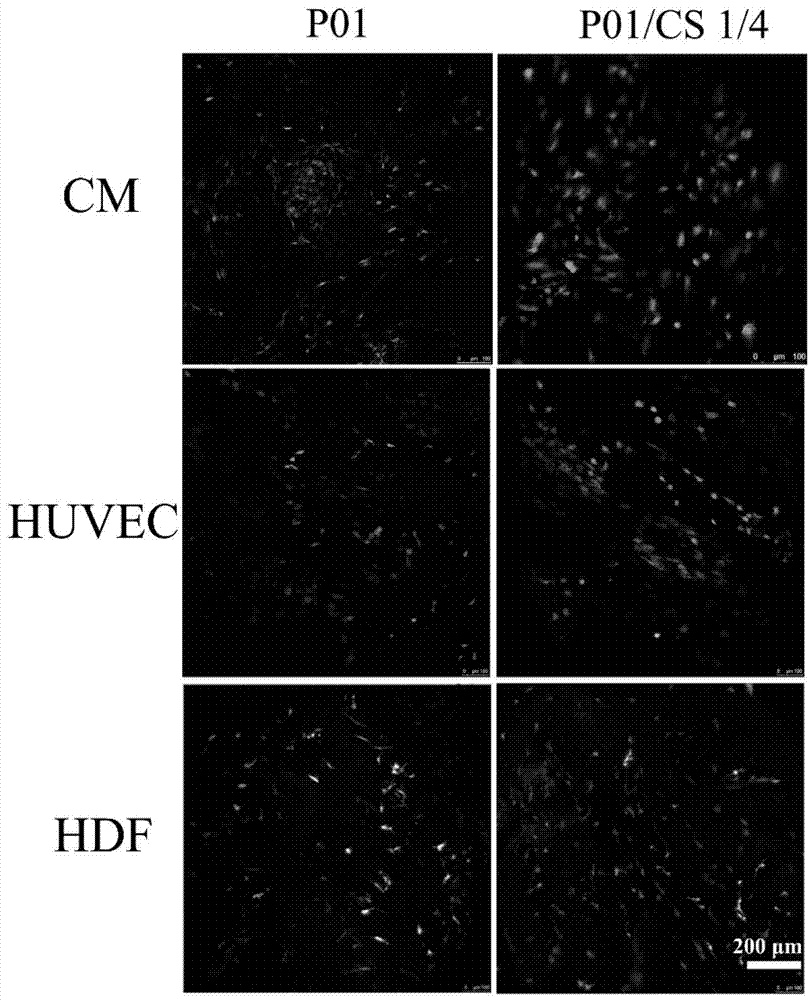

[0065] (2) Preparation of calcium silicate-decellularized myocardial matrix composite material:

[0066] The decellularized myocardial matrix with a diameter of 10 mm was submerged in 300 μL of calcium silicate extracts with dilution factors of 64, 16, and 4 times, respectively. Place in a cell culture incubator at 37 degrees, 5% CO 2 Soak for 48 hours under the environment. Then the composite material was taken out, placed in a minus 80 degree refrigerator to freeze, and finally freeze-dried for 24 hours.

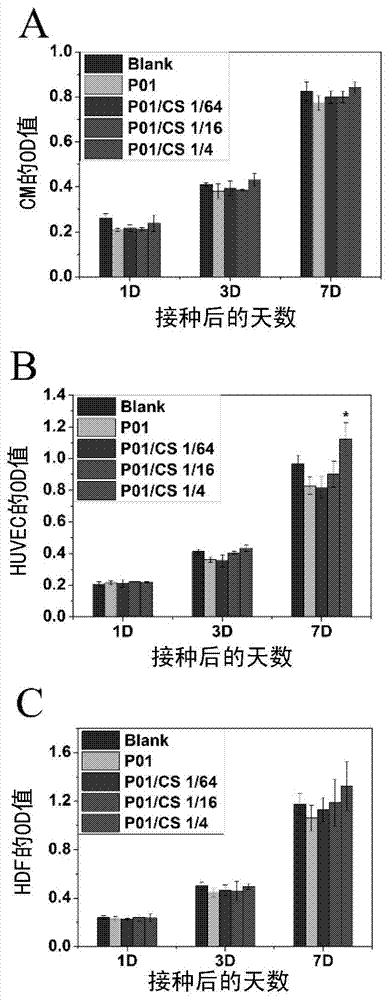

[0067] The test results of ion release showed that ( figure 1), in each group, calcium and silicon ions could be released stably within 7 days, and the daily release amount w...

Embodiment 2

[0069] (1) Preparation of calcium silicate leaching solution:

[0070] Dilute the stock solution of CS extract with cell culture medium by 64, 16, and 4 times respectively, shake it evenly at room temperature, and then pass it through a 0.22mm filter to sterilize it, store it in a refrigerator at 4°C, and store it for later use.

[0071] (2) Preparation of calcium silicate-adcellular dermal matrix composite material:

[0072] The acellular dermal matrix with a diameter of 10 mm was submerged in 300 μL calcium silicate extraction solution with dilution factors of 64, 16 and 4 times respectively. Place in a cell culture incubator at 37 degrees, 5% CO 2 Soak for 48 hours under the environment. Then the composite material was taken out, placed in a minus 80 degree refrigerator to freeze, and finally freeze-dried for 24 hours to obtain a calcium silicate-decellularized dermal matrix composite material.

Embodiment 3

[0074] (1) Preparation of calcium silicate leaching solution:

[0075] The original solution of CS extract was diluted 4 times with cell culture medium, shaken evenly at room temperature, sterilized through a 0.22mm filter, and stored in a refrigerator at 4°C for later use.

[0076] (2) Preparation of calcium silicate-collagen membrane composite material:

[0077] Submerge the 10 mm diameter collagen membrane in 300 μL calcium silicate extract and stock solution with a dilution factor of 4. Place in a cell culture incubator at 37 degrees, 5% CO 2 Soak for 48 hours under the environment. Then the composite material was taken out, placed in a minus 80 degree refrigerator to freeze, and finally freeze-dried for 24 hours.

[0078] The test results of ion release showed that ( Image 6 ), the release of calcium and silicon ions in each group was more on the first day, which were 21.0ppm and 12.9ppm respectively, and then gradually decreased, and the average release amount and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com