Bacillus subtilis JG-1 capable of producing endo-inulinase as well as preparation method and application of bacillus subtilis JG-1

A technology of Bacillus subtilis and inulin endonuclease, applied in the fields of genetic engineering and fermentation engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

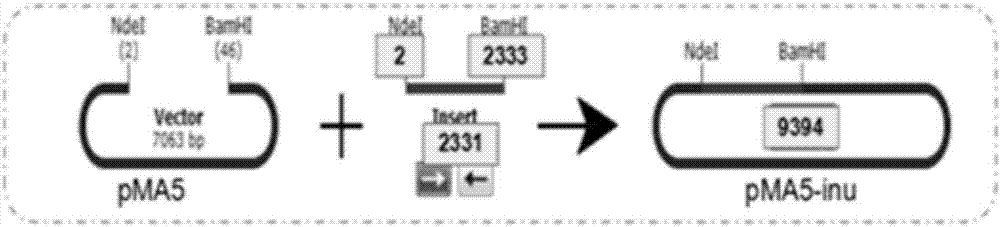

[0039] Example 1 Construction of recombinant plasmid vector pMA05-inu

[0040] Through gene mining technology, it was determined that the target gene was endoinulinase from Pseudomonas myceticum, and one-step cloning primers were designed. Dicer NdeI and BamHI double-cut the plasmid vector pMA05, recover and purify, calculate the concentration, and determine the connection system. According to the principle of homologous recombination, adopt the method of one-step cloning to connect on ice at 30°C, and use the heat shock transformation method for the connected reaction solution Transformed into DH5α, smeared on a solid LB plate containing 100 μg / ml ampicillin antibiotic, cultured overnight at 37°C for 12 hours, and screened transformants (the plasmid pMA05, which was donated by the research group of Professor Xu Hong of Nanjing University of Technology, is a large intestine-subtilis shuttle Plasmid, showing resistance to ampicillin in DH5α), pick 4-6 bacteria and transfer them...

Embodiment 2

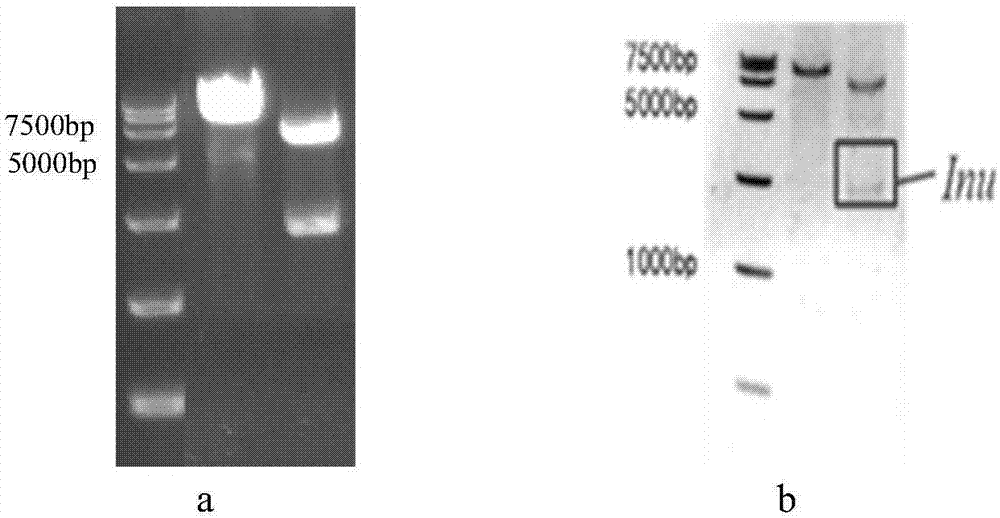

[0041] Embodiment 2: Recombinant vector transforms Bacillus subtilis (Bacillsu subtilis)

[0042] Since subtilis expression plasmid transformation methods are all chemical transformation methods, the transformation efficiency of Bacillus subtilis is higher. First, make Bacillus subtilis competent, and finally aliquot into 200μl / tube, and take 5μl of the verified correct plasmid and directly add it to 200μl In the competent Bacillus subtilis, shake the bacteria at 37°C and 200rpm for 90min, and finally smear the plate, the concentration of kanamycin antibiotic is 20μg / ml, culture overnight at 37°C, pick the transformant, and inoculate it into the liquid culture containing kanamycin antibiotic Shake the bacteria at 37°C and 200rpm for 12 hours in the base medium, and then follow the steps in Example 1 for enzyme digestion verification. The electrophoresis is shown in the attached figure 2 b: Lane 1 is Maker, lane 2 is single-enzyme digestion verification, and lane 3 is double-e...

Embodiment 3

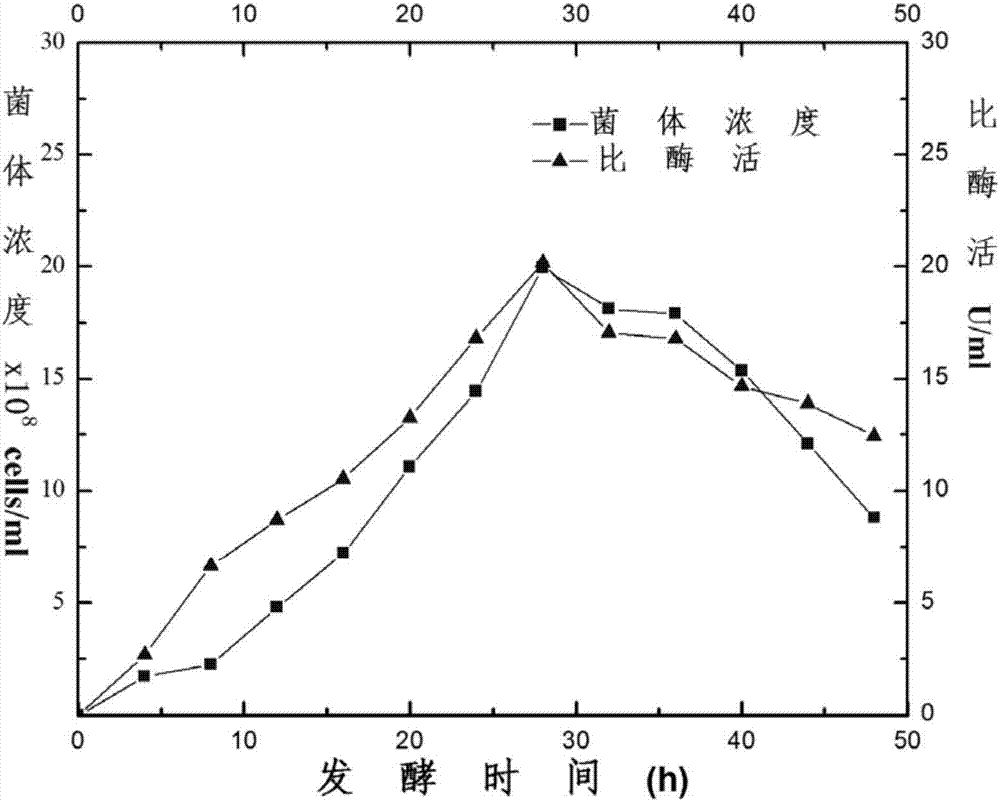

[0043] Embodiment 3: JG-1 fermentation enzyme production optimization

[0044] The screened positive clone Bacillsu subtilis JG-1 was inoculated into 500ml enzyme-producing fermentation medium to ferment to produce endo-inulinase, and the initial maximum specific enzyme activity was about 1.2U / ml. To optimize the conditions for the production of inulinase by B. subtilis JG-1, inoculate JG-1 into a 500ml shake flask, ferment at 32°C, sample every 4 hours, take 200μl of fermentation broth and 800μl of 2% The inulin was reacted for 30 minutes, and the enzyme activity of inulin endoenzyme was measured. As the fermentation progressed, the cell concentration (OD600nm) of the recombinant bacteria JG-1 reached the maximum value, which was 2.5. Centrifuged at 4°C, 9000rpm, centrifuged After 10 min, the bacterial cells were obtained, and the bacterial cells were washed twice with 200 μl of 0.02 mM phosphate buffered saline PBS (pH 7.4), and finally the bacterial cells were resuspended w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com