A kind of biological fiber facial mask base cloth and biological fiber facial mask

A technology of biological fiber mask and base cloth, which is applied in the field of skin care products, can solve the problems of poor biocompatibility, skin damage, skin sensitivity, etc., and achieve the effects of soft hand feeling, improved film formation, and improved liquid holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

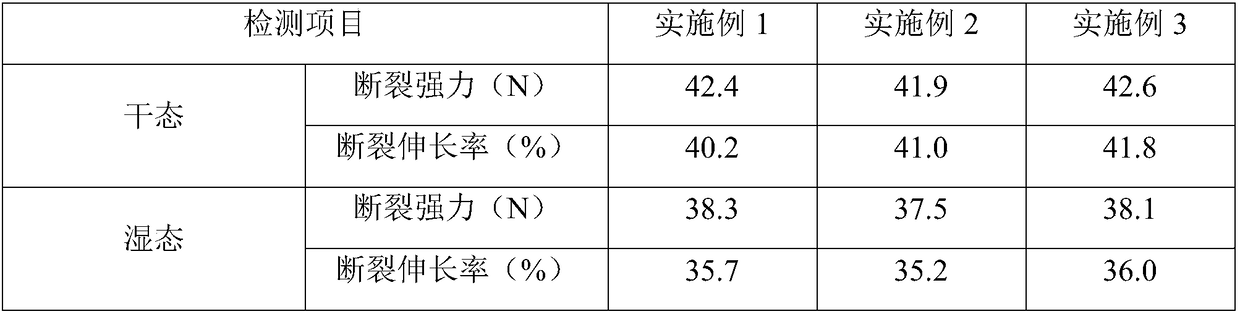

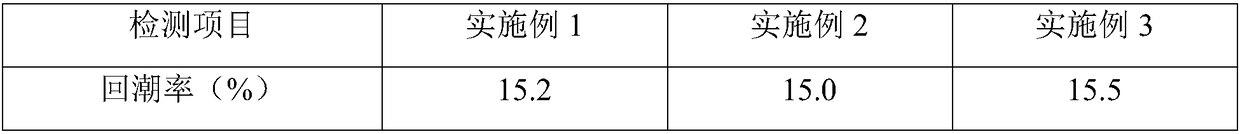

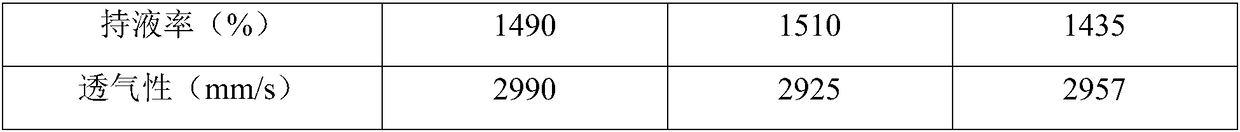

Examples

Embodiment 1

[0026] The biofiber facial mask base cloth of the present embodiment is prepared by the following method:

[0027] 1) Dissolving polylactic acid in chloroform to prepare a spinning solution with a mass concentration of polylactic acid of 20%; using the spinning solution to perform electrospinning, the parameters of the electrospinning are: the spinning outlet is 6 No. 1 needle, the spinning voltage was 20kV, the spinning pole distance (the distance between the receiving plate and the needle) was 12cm, and the flow rate of the spinning solution was 0.3ml / h; Lactic acid fiber felt;

[0028] After testing, the fiber diameter in the obtained polylactic acid fiber mat is 100-400 nm;

[0029] 2) Prepare an acetic acid aqueous solution with a mass concentration of 5%; dissolve the chitosan in the acetic acid aqueous solution to make a chitosan solution with a mass concentration of 2.0%, and then according to the mass ratio of polyvinyl alcohol and chitosan, it is 0.2:1 Add polyviny...

Embodiment 2

[0034] The biofiber facial mask base cloth of the present embodiment is prepared by the following method:

[0035] 1) Dissolving polylactic acid in chloroform to prepare a spinning solution with a mass concentration of polylactic acid of 23%; using the spinning solution for electrospinning, the parameters of the electrospinning are: the spinning outlet is 6 No. 1 needle, the spinning voltage was 15kV, the spinning pole distance (the distance between the receiving plate and the needle) was 10cm, and the flow rate of the spinning solution was 0.2ml / h; Lactic acid fiber felt;

[0036] After testing, the fiber diameter in the obtained polylactic acid fiber mat is 100-400 nm;

[0037] 2) Prepare an acetic acid aqueous solution with a mass concentration of 7%; dissolve the chitosan in the acetic acid aqueous solution to make a chitosan solution with a mass concentration of 2.3%, and then according to the mass ratio of polyvinyl alcohol and chitosan, it is 0.2:1 Add polyvinyl alcoh...

Embodiment 3

[0042] The biofiber facial mask base cloth of the present embodiment is prepared by the following method:

[0043]1) dissolving polylactic acid in chloroform to prepare a spinning solution with a mass concentration of polylactic acid of 25%; using the spinning solution for electrospinning, the parameters of the electrospinning are: the spinning outlet is 8 No. 1 needle, the spinning voltage was 25kV, the spinning pole distance (the distance between the receiving plate and the needle) was 15cm, and the flow rate of the spinning solution was 0.4ml / h; Lactic acid fiber felt;

[0044] After testing, the fiber diameter in the obtained polylactic acid fiber mat is 100-400 nm;

[0045] 2) Prepare an acetic acid aqueous solution with a mass concentration of 10%; dissolve the chitosan in the acetic acid aqueous solution to make a chitosan solution with a mass concentration of 2.5%, and then according to the mass ratio of polyvinyl alcohol and chitosan, it is 0.3:1 Add polyvinyl alcoh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com