Ultrasonic atomization preparation method of porous hollow spherical ternary positive electrode material

A cathode material, ultrasonic atomization technology, applied in electrode manufacturing, electrical components, battery electrodes, etc., to simplify the synthesis process, improve high-current charge-discharge performance and cycle performance, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

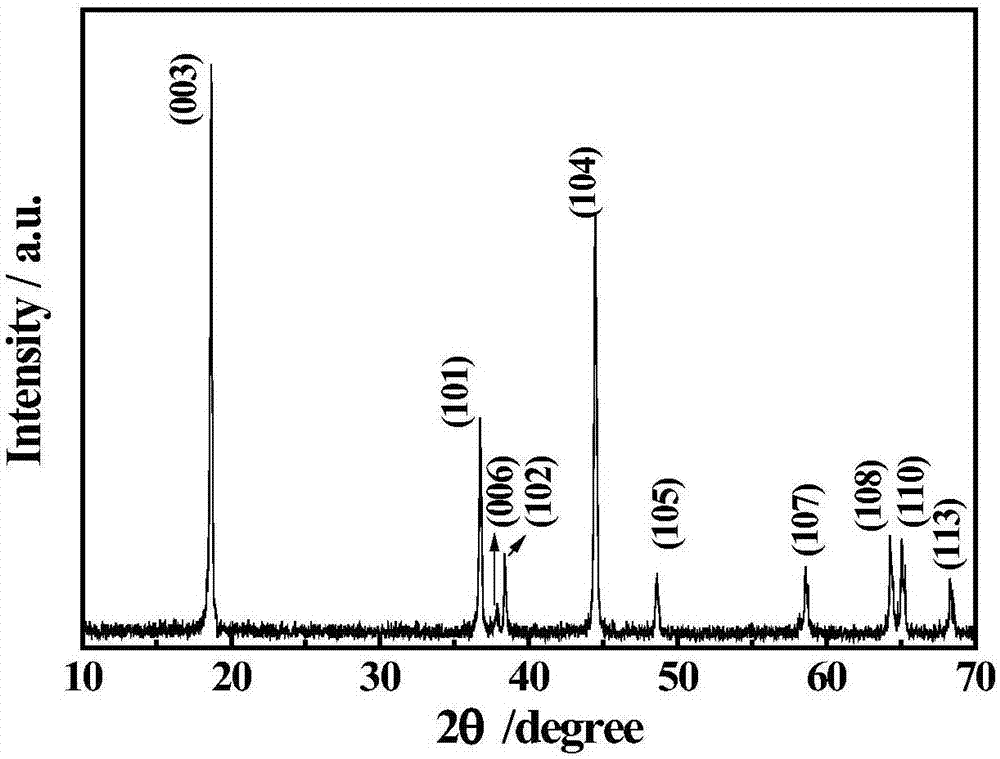

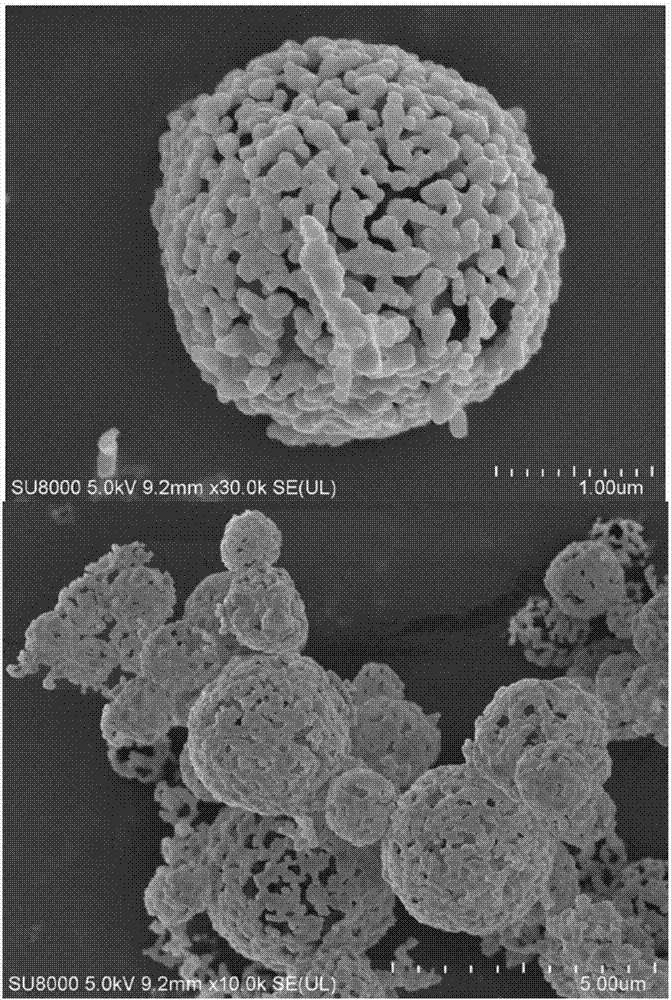

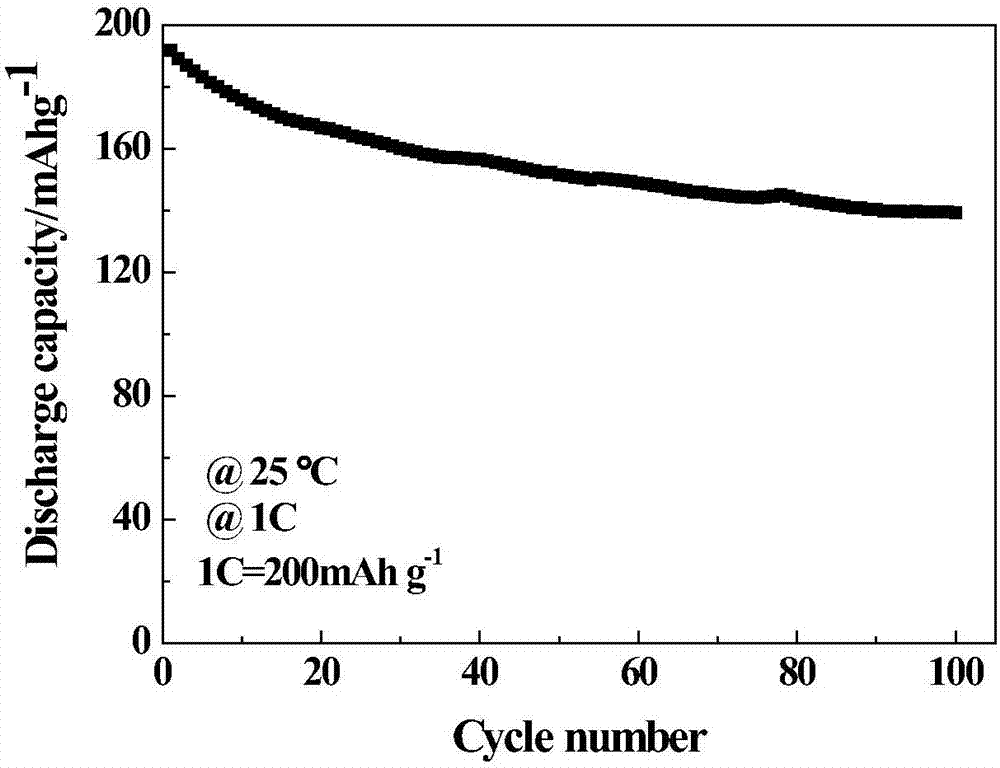

[0035] Hollow spherical porous LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2

[0036] Take by weighing 2.142 grams of lithium acetate, 1.659 grams of nickel acetate, 1.661 grams of cobalt acetate, and 1.634 grams of manganese acetate and dissolve them in 50 milliliters of deionized water, add 3.0821 grams of citric acid after stirring continuously at room temperature for 30 minutes, drip ammonia water in the stirring state, and adjust The pH value of the solution, the pH value of the solution is controlled at about 6.9, and then continuously stirred in a water bath at 60° C. for 4 hours to obtain a precursor solution for ultrasonic atomization.

[0037] Be that the solution obtained by atomizing the ultrasonic atomization system of 1.7MHz with the oscillation frequency, the atomization amount is 0.2 milliliters per minute, and the atomized droplet that produces is loaded into the tube furnace that temperature is 700 ° C by vacuum pump, The moving speed of the mist in the quartz tube is 2 cm / ...

Embodiment 2

[0043] Spherical Porous LiNi 0.5 co 0.2 mn 0.3 o 2

[0044] Weigh 2.687 grams of lithium sulfate, 2.628 grams of nickel sulfate, 1.124 grams of cobalt sulfate, and 1.014 grams of manganese sulfate and dissolve them in 50 milliliters of deionized water. After stirring continuously at room temperature for 30 minutes, add 3.0821 grams of citric acid, drip ammonia water in the stirring state, and adjust The pH value of the solution, the pH value of the solution is controlled at about 6.8, and then continuously stirred in a water bath at 60° C. for 12 hours to obtain a precursor solution for ultrasonic atomization. Be the solution obtained by atomizing the ultrasonic atomization system of 2.4MHz with the oscillation frequency, the atomization amount is 0.2 milliliters per minute, and the atomized liquid droplet that produces is loaded into the tube furnace that temperature is 750 ° C by vacuum pump, The moving speed of the mist in the quartz tube is 3 cm / s, and the dried precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com