Modified electrode for full-vanadium flow battery and preparation method thereof

An all-vanadium redox flow battery, modified electrode technology, applied in battery electrodes, nanotechnology for materials and surface science, fuel cells, etc., can solve problems such as battery efficiency to be improved, poor conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a modified electrode applied to an all-vanadium redox flow battery according to an embodiment of the present invention includes:

[0022] Weigh SnCl according to the ratio of the amount of substances weighed 91:9 4 ·5H 2 O and SbCl 3 ;

[0023] Then the above SnCl 4 ·5H 2 O and SbCl 3 The mixture was dissolved in isopropanol, and after melting, the SnO 2 with Sb 2 o 3 The mass concentration of the sum of the mass is 10-20g / L.

[0024] Then, after magnetic stirring at 80° C. for 0.5 h, a light yellow solution was obtained;

[0025] Obtain light yellow, clear and transparent flowable sol after aging for 24 hours;

[0026] Slowly immerse the treated carbon paper or carbon felt in the above sol with a pulling device for 5 minutes, then pull it up vertically and steadily at a uniform speed of 5 cm / min, and dry it in an oven at 100°C for 15 minutes; in order to prepare different For the modified electrode with loading capacity, repeat the abo...

Embodiment 1

[0043] Weigh 2.12g SnCl 4 ·5H 2 O and 0.14 g of SbCl 3 , and then the above 2.12g SnCl 4·5H 2 O and 0.14 g of SbCl 3 The mixture was dissolved in 100mL isopropanol, the mass concentration (as SnO 2 with Sb 2 o 3 ) was 10 g / L, and then magnetically stirred for 0.5 h at 80° C. to obtain a light yellow solution. After aging for 24 hours, a light yellow, clear, transparent and flowable sol was obtained. Use a pulling device (HTDC-300 dipping and pulling coating machine, stroke 5cm, pulling speed 5cm / min) to slowly enter the treated carbon paper into the sol for 5min, and then lift it vertically and steadily at a uniform speed of 5cm / min. Pull it up and dry it in an oven at 100°C for 15 minutes. Repeat the above steps. Pulling 5 times, the loading capacity of nanoparticles is 0.1mg / cm 2 . Finally, the dried carbon paper was placed in a tube furnace and calcined at 450 °C for 90 min. The loading capacity of the prepared nanoparticles was 0.1 mg / cm 2 The modified electr...

Embodiment 2

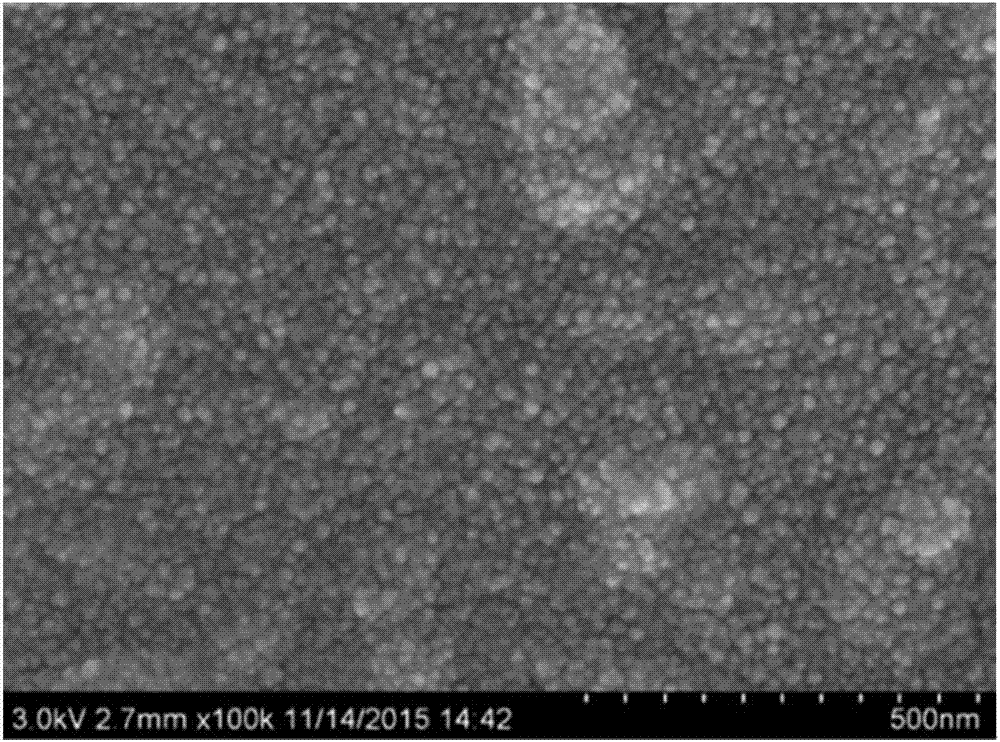

[0045] Weigh 3.18g SnCl 4 ·5H 2 O and 0.21 g of SbCl 3 . Then the 3.18g SnCl 4 ·5H 2 O and 0.21 g of SbCl 3 The mixture was dissolved in 100mL isopropanol, the mass concentration (as SnO 2 with Sb 2 o 3 ) was 10 g / L, and then magnetically stirred for 0.5 h at 80° C. to obtain a light yellow solution. After aging for 24 hours, a light yellow, clear, transparent and flowable sol was obtained. Use a pulling device (HTDC-300 dipping and pulling coating machine, stroke 5cm, pulling speed 5cm / min) to slowly enter the treated carbon paper into the sol for 5min, and then lift it vertically and steadily at a uniform speed of 5cm / min. Pull it up and dry it in an oven at 100°C for 15 minutes. Repeat the above steps. Pulling 8 times, the loading capacity of the prepared nanoparticles is 0.2mg / cm 2 . Finally, the dried carbon paper was placed in a tube furnace and calcined at 500 °C for 90 min. Electron micrographs of the obtained modified electrodes are shown in figure 1 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com