A method for treating phenol wastewater by adsorption method and pH-sensitive adsorbent

A technology of adsorbent and adsorption method, which is applied in the field of adsorption method to treat phenol wastewater, which can solve the problems of long operation time, affecting the promotion of engineering application, and large consumption of reagents, etc., and achieves the effect of high adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

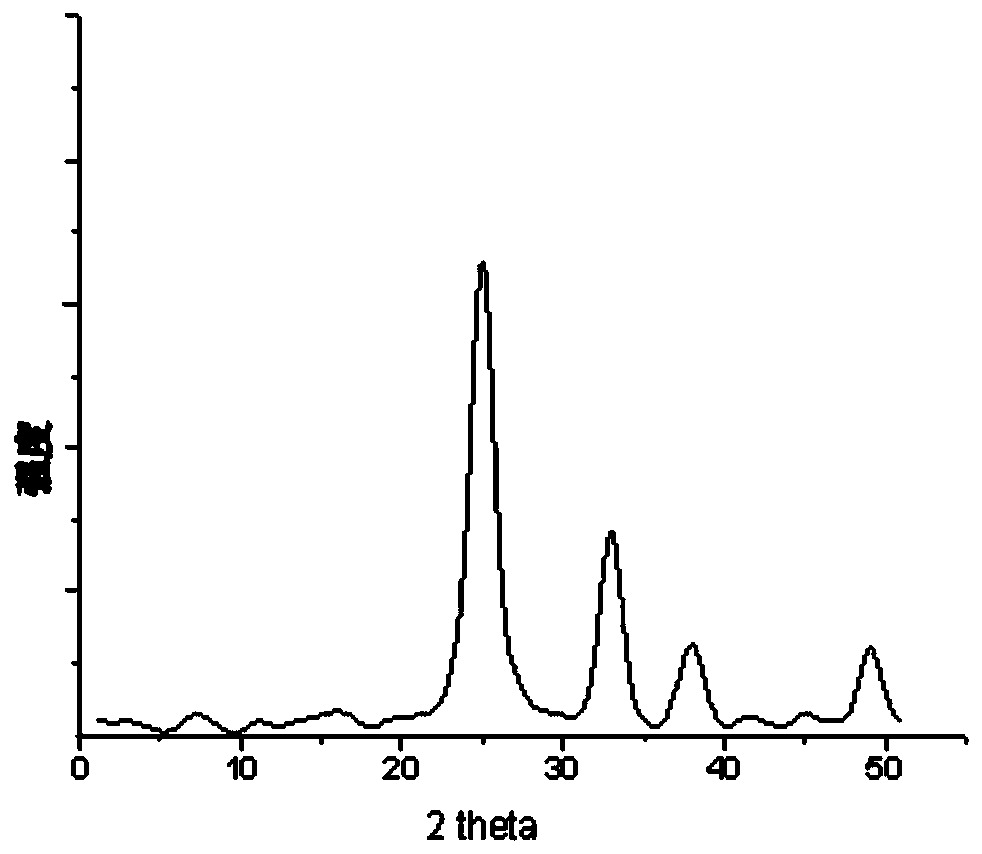

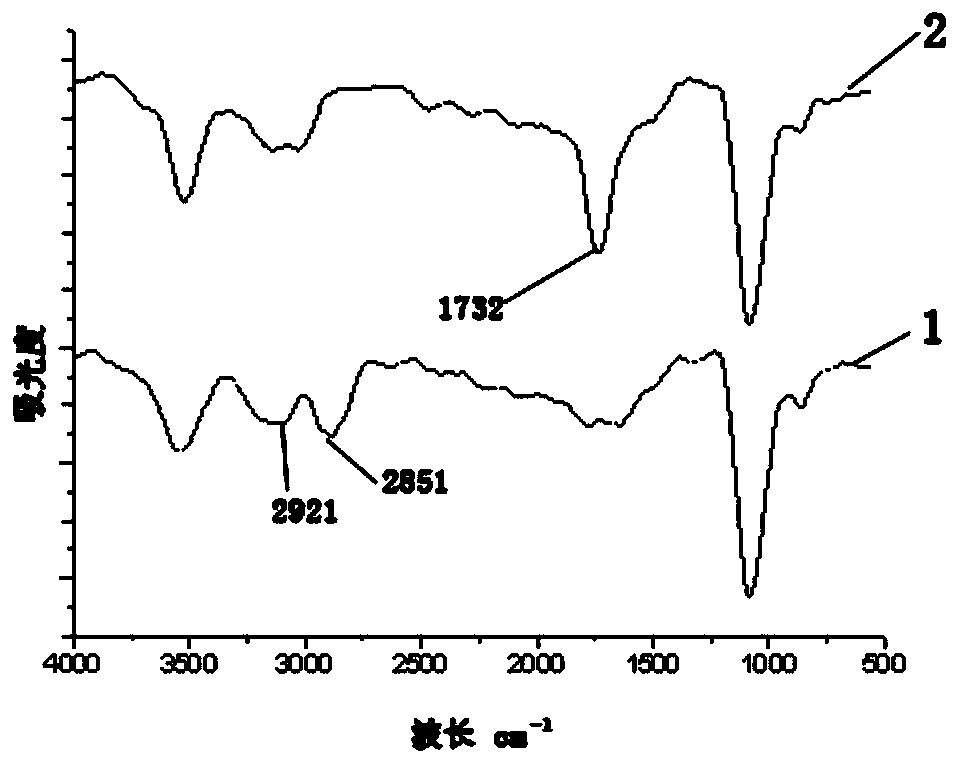

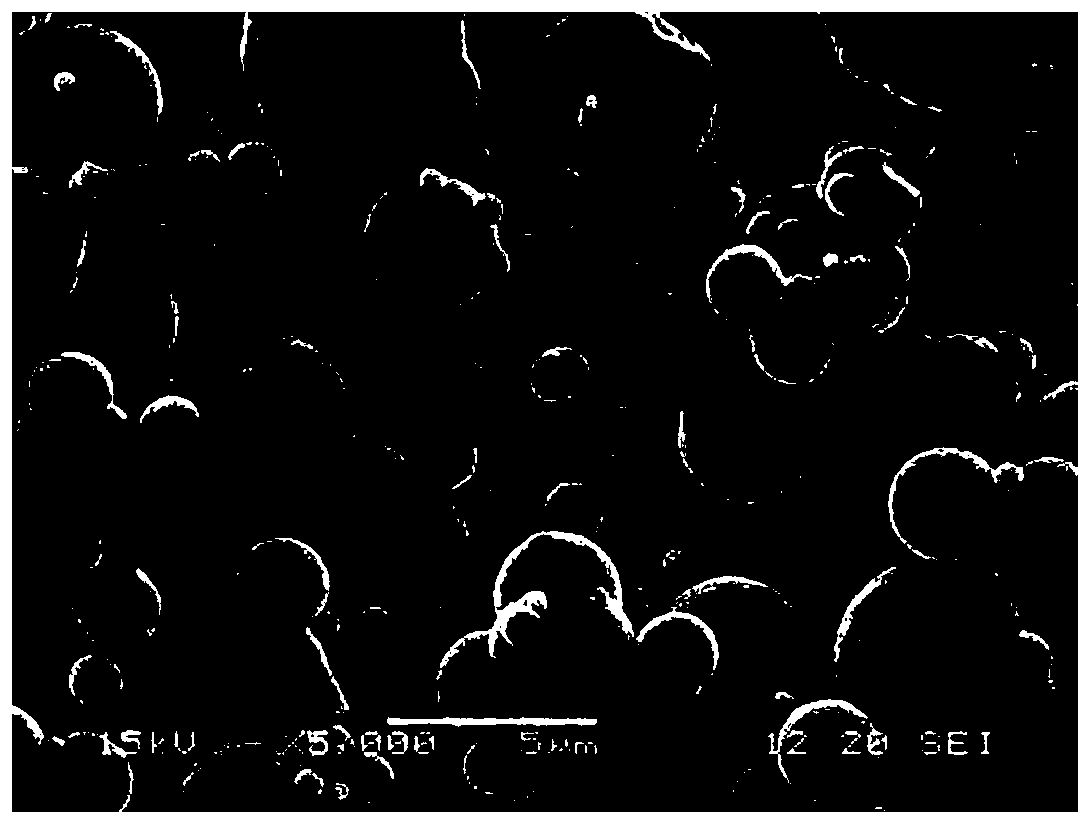

[0033] The preparation method of adsorbent, comprises the steps:

[0034] Step 1, by weight, take 6 parts of cetyltrimethylammonium bromide (CTAB), add to 550 parts of deionized water, stir and dissolve, then add 90 parts of ethylene glycol and 35 parts of triethanolamine , mix evenly; then add 40 parts of tetrabutyl titanate (TBOT) to carry out the hydrolysis reaction at elevated temperature, the temperature of the hydrolysis reaction is 65°C, and the reaction time is 4h. After the reaction, the product is centrifuged and washed with ethanol and water in turn Finally, the powder is added to 850 parts of acidic ethanol solution. The acidic ethanol solution is formed by mixing concentrated hydrochloric acid and ethanol according to a volume ratio of 1:15. , the heating and reflux temperature is 75°C, and the reflux time is 3 hours. The powder is centrifuged, washed with water, and vacuum-dried to obtain mesoporous titanium oxide particles;

[0035] Step 2, in parts by weight, ...

Embodiment 2

[0042] The preparation method of adsorbent, comprises the steps:

[0043] Step 1, in parts by weight, take 3 parts of cetyltrimethylammonium bromide (CTAB), add it to 400 parts of deionized water, stir and dissolve, then add 80 parts of ethylene glycol and 20 parts of triethanolamine , mix evenly; then add 30 parts of tetrabutyl titanate (TBOT) to carry out the hydrolysis reaction at elevated temperature, the temperature of the hydrolysis reaction is 55°C, and the reaction time is 1h. After the reaction, the product is centrifuged and washed with ethanol and water in turn Finally, add the powder to 800 parts of acidic ethanol solution. The acidic ethanol solution is formed by mixing concentrated hydrochloric acid and ethanol at a volume ratio of 1:12. , the heating and reflux temperature is 70°C, the reflux time is 1h, the powder is centrifuged, washed with water, and vacuum-dried to obtain mesoporous titanium oxide particles;

[0044] Step 2, in parts by weight, take 10 part...

Embodiment 3

[0048] The preparation method of adsorbent, comprises the steps:

[0049] Step 1, in parts by weight, take 5 parts of cetyltrimethylammonium bromide (CTAB), add it to 450 parts of deionized water, stir and dissolve, then add 85 parts of ethylene glycol and 25 parts of triethanolamine , mix evenly; then add 35 parts of tetrabutyl titanate (TBOT) to carry out the hydrolysis reaction at elevated temperature, the temperature of the hydrolysis reaction is 60°C, and the reaction time is 2h. After the reaction, the product is centrifuged and washed with ethanol and water in turn Finally, add the powder to 12 parts of acidic ethanol solution. The acidic ethanol solution is formed by mixing concentrated hydrochloric acid and ethanol according to the volume ratio of 1:13. The concentration of the concentrated hydrochloric acid is 28wt%, and the template is removed by heating , the heating and reflux temperature is 72°C, and the reflux time is 2 hours. The powder is centrifuged, washed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com