Preparation method of VP/alpha-olefin copolymer and VP/alpha-olefin copolymer

An olefin copolymer and olefin technology, which is applied in the preparation of VP/α-olefin copolymers, and the field of VP/α-olefin copolymers, can solve the problem of increasing the content of cross-linked gelling impurities, production costs, product application limitations, and restrictions on copolymerization. Product production efficiency and other issues, to achieve high reaction efficiency, avoid cross-linking gel and chain scission, and achieve uniform and controllable copolymerization reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

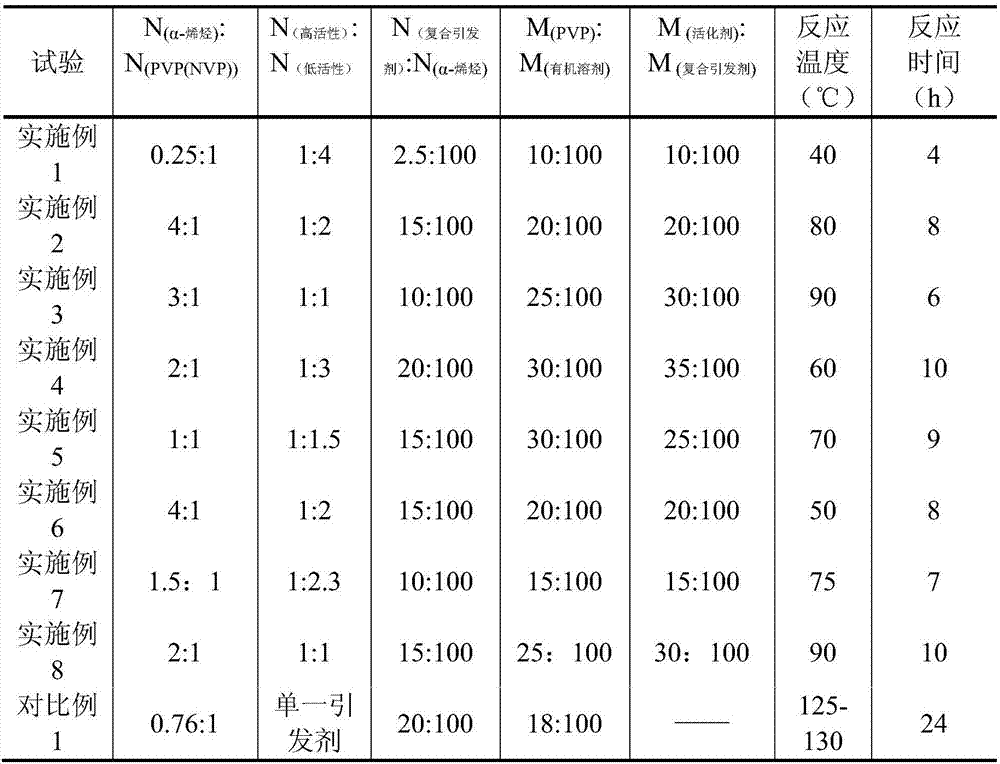

Examples

Embodiment 1

[0054] The preparation of embodiment 1, VP / α-olefin copolymer

[0055] (1), α-olefin preactivation

[0056] Mix 3.59g of dodecene and 3.59g of ethanol evenly, add 0.0718g of triisobutylaluminum for preactivation, and obtain mixture A for subsequent copolymerization; the preactivation temperature is controlled at 10°C, and the preactivation time is 30 minutes , The pre-activation process is a reflux process under the protection of nitrogen.

[0057] (2), pre-copolymerization reaction

[0058] Add 10g of PVPK15, 0.19g of dodecene, 0.027g of benzoyl peroxide, 0.041g of tert-butyl peroxide, 0.0068g of ascorbic acid, and 100g of ethanol into a four-necked flask with a stirring and condensing device, and stir until completely dissolved Afterwards, nitrogen gas was introduced for replacement, and then the pre-copolymerization reaction was carried out at 40°C. The pre-copolymerization reaction was a reflux reaction, and the pre-copolymerization reaction time was controlled to be 30 ...

Embodiment 2

[0063] The product VP / α-olefin copolymer is a white solid, insoluble in water, and has good solubility in hydrocarbon solvents. Detect residual single and residual initiator in the product respectively, as shown in Table 2. After calculation, the grafting rate of monomer olefin is 100%. The preparation of embodiment 2, VP / α-olefin copolymer

[0064] (1), α-olefin preactivation

[0065] Mix 151.3g of hexadecene and 90.5g of isopropanol evenly, add 6.44g of triethylaluminum for preactivation, and obtain mixture A for subsequent copolymerization; the preactivation temperature is controlled at 15°C, and the preactivation time is 40 Minutes, the pre-activation process is a reflux process under the protection of nitrogen.

[0066] (2), pre-copolymerization reaction

[0067] Add 20g of PVPK30, 9.66g of hexadecene, 4.24g of diacetyl peroxide, 10.49g of di-tert-butyl peroxide, 2.946g of ascorbic acid, and 100g of isopropanol into a four-necked flask with a stirring and condensing d...

Embodiment 3

[0073] The preparation of embodiment 3, VP / α-olefin copolymer

[0074] (1), α-olefin preactivation

[0075] Mix 52.2g of hexene and 26.1g of 3-methyl-1-butanol evenly, add 2.838g of diethylaluminum chloride for preactivation, and obtain mixture A for subsequent copolymerization; the preactivation temperature is controlled at 25 °C, the pre-activation time is 50 minutes, and the pre-activation process is a reflux process under the protection of nitrogen.

[0076] (2), pre-copolymerization reaction

[0077] Add 25g PVPK90, 4.54g hexene, 5.41g tert-butyl peroxyisobutyrate, 9.13g dicumyl peroxide, 4.36g BHT, 100g 3-methyl-1-butanol respectively into the In the four-necked flask of the device, stir until the dissolution is complete, pass nitrogen replacement protection, and then control the pre-copolymerization reaction at 90 ° C, the pre-copolymerization reaction is a reflux reaction, and the time of the pre-copolymerization reaction is controlled for 40 minutes to obtain a pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com