Method for preparing nonlinear resistor based on hydrogenated rare earth nickel-based perovskite oxide

A technology of perovskite oxide and non-linear resistance, applied in the direction of electrical components, etc., can solve the problems of non-linear change of material resistance and reduce the bonding effect of nickel-oxygen octahedron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

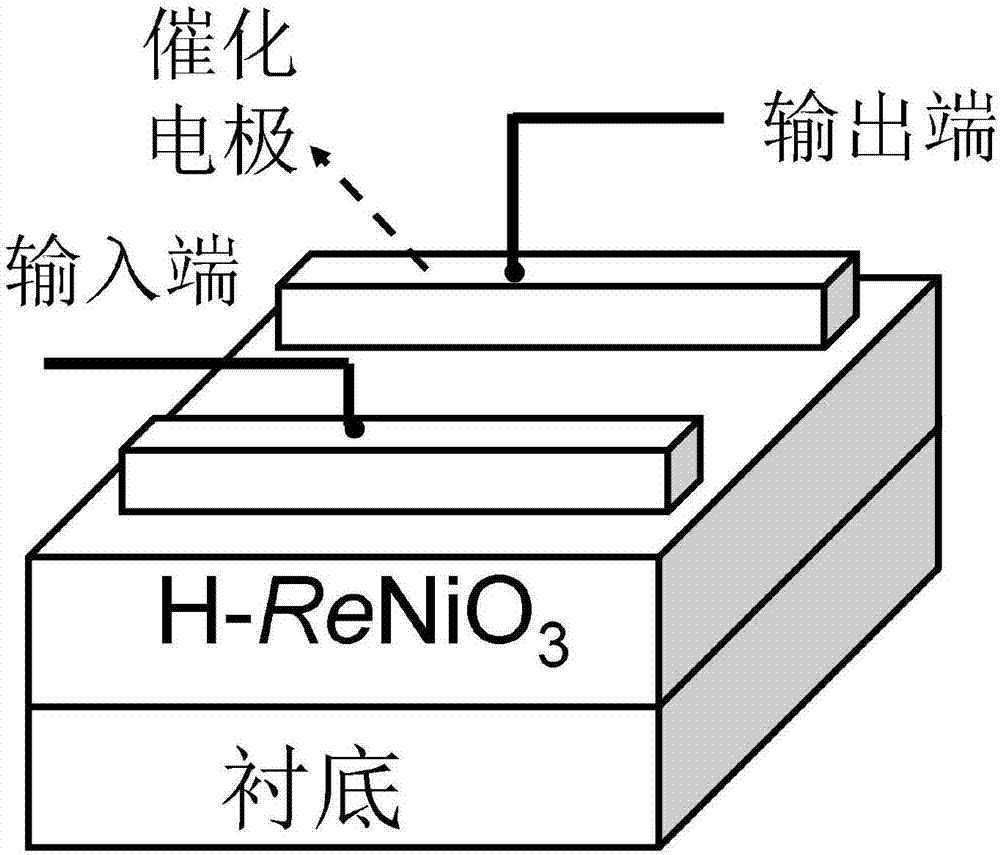

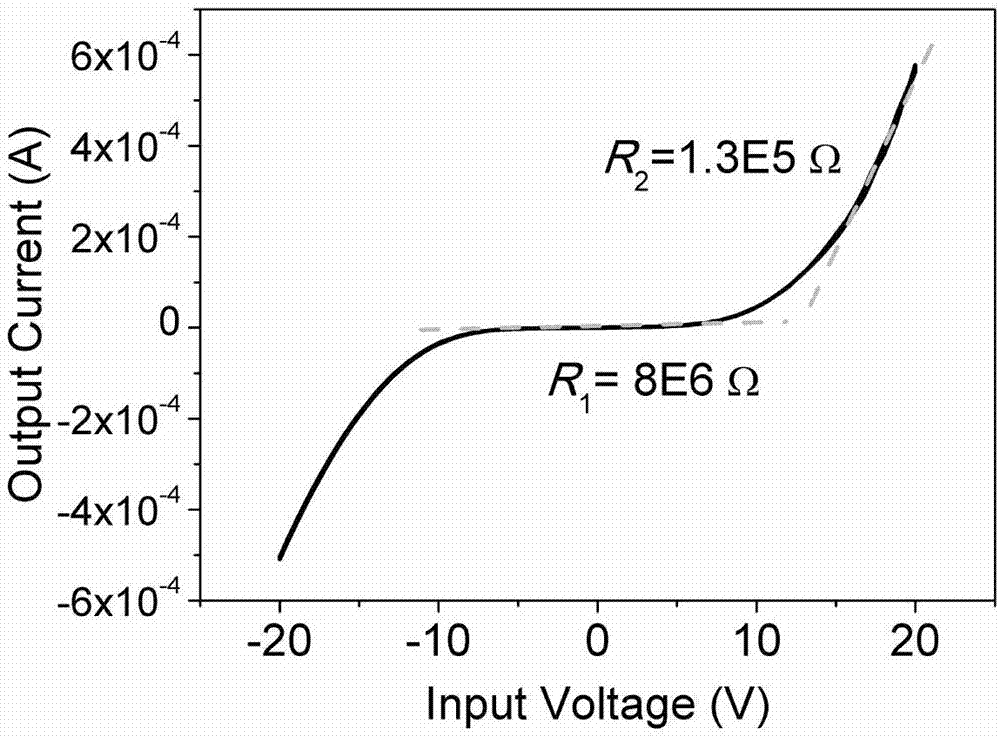

[0025] Pt / H-SmNiO 3 The preparation and application method of the / Si electrically triggered bidirectional non-linear resistance are as follows: 200 nanometers of samarium nickel oxide (SmNiO) are grown on a square silicon substrate with a side length of 10 mm. 3 ) polycrystalline film. Strip metal platinum catalytic electrodes are prepared on the surface of the film. The electrode size is: 10 mm long, 0.5 mm wide, and 100 nm thick; the platinum strips are arranged in parallel with each other in the array, with a spacing of 1 mm. The samarium-nickel-oxygen thin-film material deposited with platinum-catalyzed electrode arrays was exposed to 1% H 2 / He mixed gas at 300 degrees Celsius for 30 minutes for hydrogenation treatment. In actual use, two adjacent platinum catalytic electrodes are used as signal input and output terminals, and a voltage is applied between the two electrodes to measure the current. figure 1 The device structure is illustrated. figure 2The measured I-...

Embodiment 2

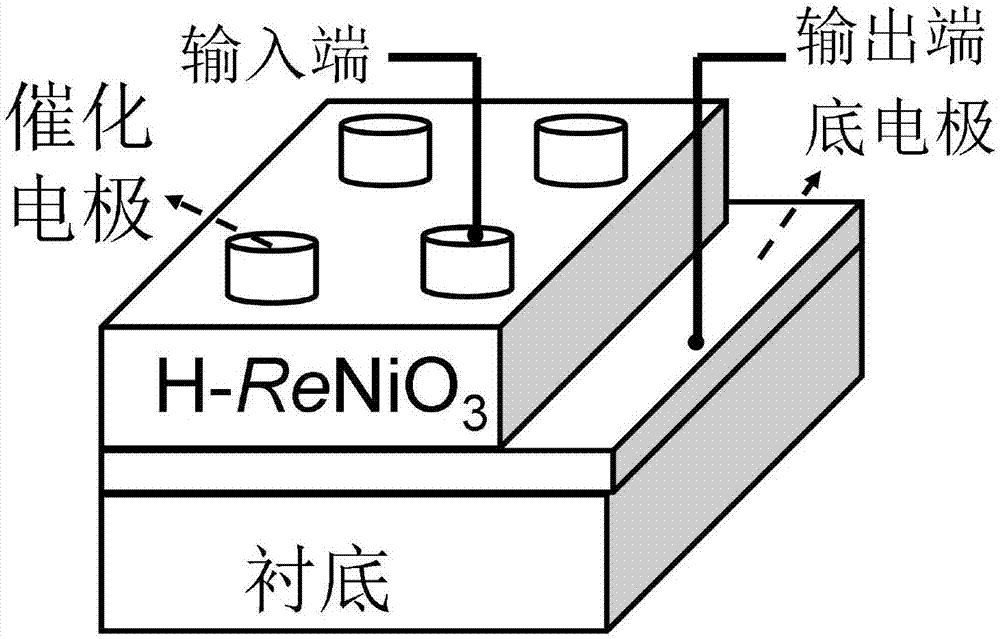

[0027] Pt / H-SmNiO 3 / SrRuO 3 / Si electric trigger unidirectional non-linear resistance preparation and use method, specifically as follows: grow 100 nanometers of strontium rubidium oxide film bottom electrode on the square silicon substrate of side length 10 millimeters, grow 200 nanometers of samarium nickel oxide (SmNiO) on the bottom electrode 3 ) polycrystalline film. A cylindrical metal platinum catalytic electrode is prepared on the surface of the film. The electrode size is 50 microns in diameter and 100 nanometers in thickness; the platinum electrodes in the whole array are arranged in a square two-position lattice, and the distance between the platinum electrodes is 150 microns. The samarium-nickel-oxygen film deposited with the platinum-catalyzed electrode array was exposed to 1% H 2 / He mixed gas at 300 degrees Celsius for 30 minutes for hydrogenation treatment. In actual use, the bottom electrode and each platinum catalytic electrode are used as signal input an...

Embodiment 3

[0029] Pt / H-SmNiO 3 / SrTiO 3 The preparation and application method of the electrically triggered bidirectional non-linear resistance are as follows: in a square strontium titanate (SrTiO 3 ) growth of 200 nm samarium nickel oxide (SmNiO 3 ) polycrystalline film, by controlling the growth conditions to make the epitaxial coherent growth of the film material, that is, the film is a quasi-single crystal material and is in a state of tensile stress. Strip metal platinum catalytic electrodes are prepared on the surface of the film. The electrode size is: 10 mm long, 0.5 mm wide, and 100 nm thick; the platinum strips are arranged in parallel with each other in the array, with a spacing of 1 mm. The samarium-nickel-oxygen thin-film material deposited with platinum-catalyzed electrode arrays was exposed to 1% H 2 / He mixed gas at 300 degrees Celsius for 30 minutes for hydrogenation treatment. In actual use, two adjacent platinum catalytic electrodes are used as signal input and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com