Cellulose composition

A technology of cellulose and composition, applied in the field of cellulose composition, can solve the problems of easily cracked or missing products, not fluffy and light, low density and hardness, etc., achieve excellent suspension stability, excellent dispersion stability, flavor excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

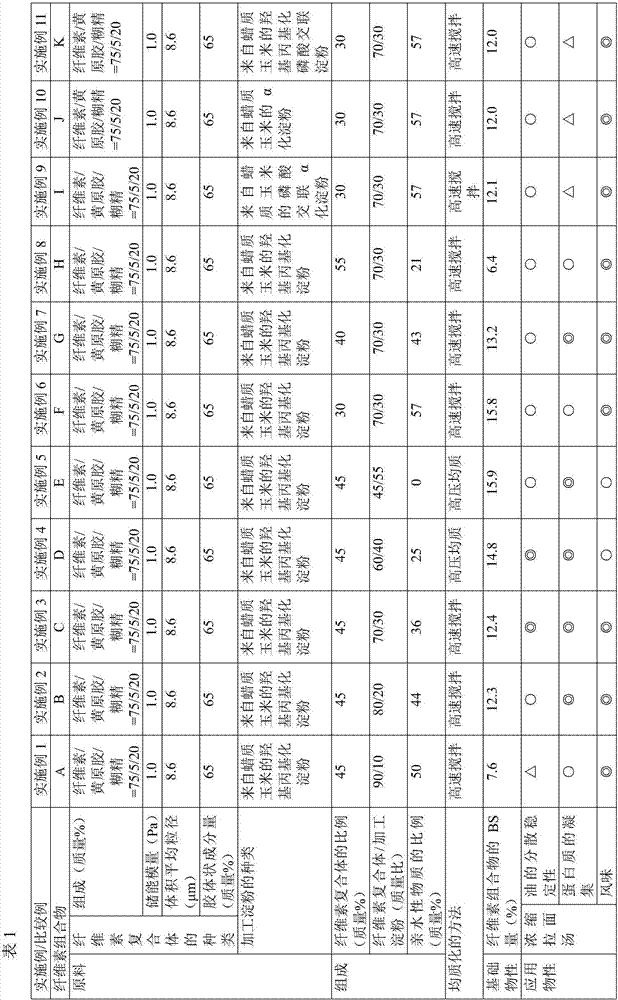

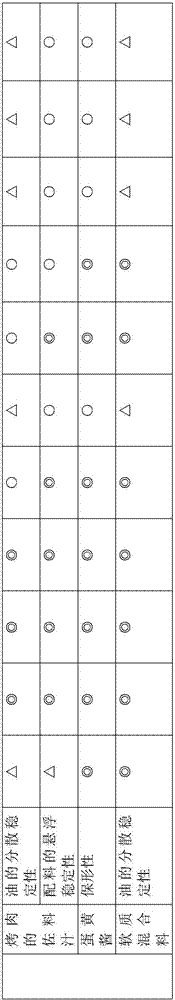

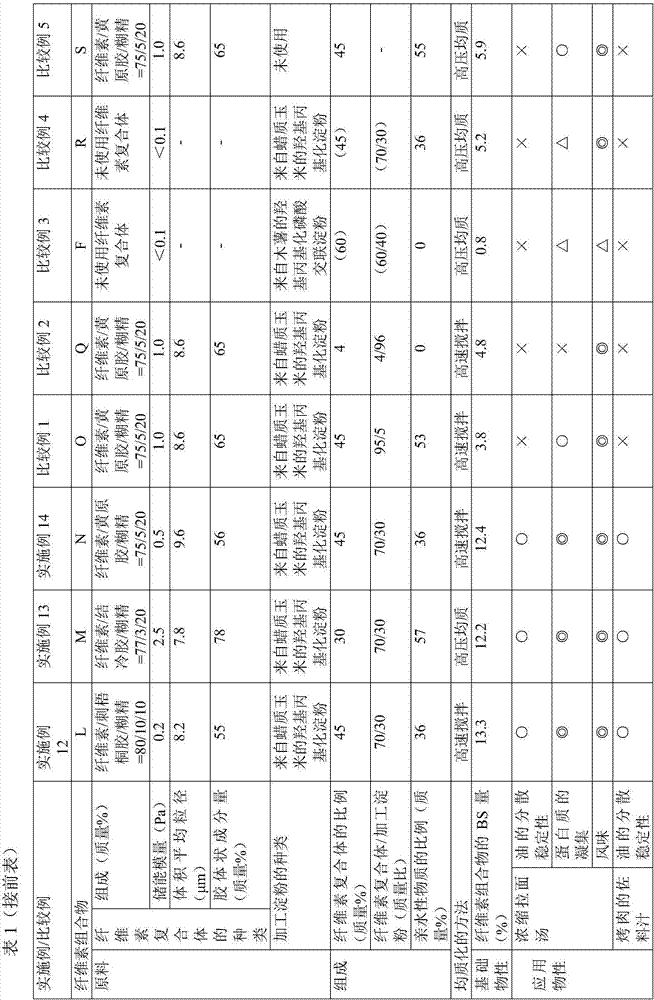

Examples

Embodiment 1

[0413] 1) Dispersion / homogenization process

[0414] Using a high-speed stirrer (trade name TK Homogenizing Mixer MARKII manufactured by Primicus Co., Ltd.), 1500 g of tap water at 25° C. was stirred at 2000 rpm, and 250 g of dextrin (trade name Sundec #100 manufactured by Sanwa Starch) was added as a hydrophilic substance, and Stir for 5 minutes. After that, 25 g of hydroxypropylated starch (trade name delica WH manufactured by Nichiden Chemical Co., Ltd.) derived from waxy corn starch was added as modified starch, and stirred for further 5 minutes. Then, add a complex of cellulose and xanthan gum as a cellulose complex (trade name SEORAS RC-N30 manufactured by Asahi Kasei Chemical Co., Ltd., composition: cellulose / xanthan gum / dextrin=75 / 5 / 20 (mass ratio), storage modulus (G'): 1.0 Pa, volume average particle diameter 8.6 μm, colloidal component content 65% by mass), and stirred at 12000 rpm for 60 minutes to make it into a dispersion.

[0415] 2) Drying process

[0416] The...

Embodiment 2

[0437] In addition to 220 g of dextrin (trade name Sundec #100 manufactured by Sanwa Starch Co., Ltd.), 55 g of hydroxypropylated starch derived from waxy corn starch (trade name Delica WH manufactured by Nichiden Chemical), cellulose, and xanthan gum (Asahi Kasei Chemical Co., Ltd. product name SEORAS RC-N30) was set to 225 g, and the rest were dispersed / homogenized and dried in the same manner as in Example 1 to obtain a cellulose composition B. Table 1 shows the results of measuring the BS content of the obtained cellulose composition B.

[0438] In addition, using the cellulose composition B, evaluation of applied physical properties was performed in the same manner as in Example 1. The obtained results are shown in Table 1.

[0439] As a result of measuring the viscoelasticity of ramen soup and sauce, (tanδ(50°C) / tanδ(25°C)) was 1.3.

Embodiment 3

[0441] In addition to 180 g of dextrin (trade name Sundec #100 manufactured by Sanwa Starch), 95 g of hydroxypropylated starch derived from waxy corn starch (trade name Delica WH manufactured by Nichiden Chemical), cellulose, and xanthan gum The composite (trade name SEORAS RC-N30 manufactured by Asahi Kasei Chemical Co., Ltd.) was set to 225 g, and the rest were dispersed / homogenized and dried in the same manner as in Example 1 to obtain a cellulose composition C. Table 1 shows the results of measuring the BS content of the obtained cellulose composition C.

[0442] In addition, using the cellulose composition C, evaluation of applied physical properties was performed in the same manner as in Example 1. The obtained results are shown in Table 1.

[0443] As a result of measuring the viscoelasticity of ramen soup and sauce, (tanδ(50°C) / tanδ(25°C)) was 1.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com