Biological and physical dual-preservation storage method for sandwiches

A biophysical and sandwich technology, applied in biological packaging, food science, preservation of bakery products, etc., can solve the problems of food waste and short storage time, and achieve the effect of ensuring high content, fresh luster, and maintaining internal and external air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

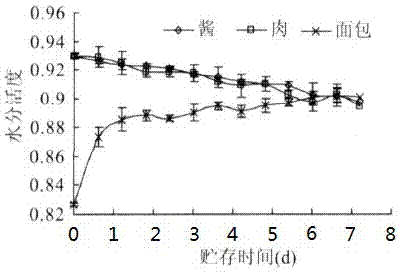

[0030] Dissolve 1% chitosan, 3% tea polysaccharide, 8% peanut red coat extract, and 0.01% citral as biologically active substances in water, spray on the inner wall of packaging bags and box-type containers, and dry at room temperature to form a natural plastic wrap; Pre-cool the fresh sandwiches after sterilization, put them into the packaging container, and seal the packaging container; fill the packaging container with a mixed gas of 26% carbon dioxide, 73% nitrogen, and 1% carbon monoxide, control the 81.5% of the inside of the packaging container, and close the inflation port; Use 42ml of the above mixed gas per 100g sandwich, and maintain the balance of internal and external air pressure; after sealing, the oxygen content in the package is reduced to 0.5%; the packaging container is boxed, double-layer material, the outer layer is kraft paper, and the inner layer is nano-scale polyolefin-based film , the inner wall of the inner layer is added with a fresh-keeping coating....

Embodiment 2

[0032]Dissolve 1.5% chitosan, 1.5% tea polysaccharide, 3.5% peanut red coat extract, and 0.1% citral in water; spray it on the inner wall of packaging bags and box-type containers, and cure and dry it with ultraviolet radiation to become a natural plastic wrap; fresh sandwiches Pre-cool after sterilization, put it into the packaging container, and seal the packaging container; fill the packaging container with a mixed gas of 28% carbon dioxide, 70.5% nitrogen, and 1.5% carbon monoxide, and use 48ml of the above-mentioned mixed gas to control the packaging container for each 100g sandwich The humidity is 82%, and the air filling port is closed; the inner wall of the packaging container is added with a fresh-keeping coating;

[0033] Among them, chitosan is chitosan obtained by deacetylation of crab chitin, peanut red coat extract contains non-starch polysaccharide and proanthocyanidin, and non-starch polysaccharide proanthocyanidin is peanut obtained by extracting peanut red coa...

Embodiment 3

[0036] Dissolve 4.5% chitosan, 6.5% tea polysaccharide, 2.5% peanut red coat extract, and 0.25% citral in water, spray it on the inner wall of the packaging bag and box container, and dry it with far-infrared radiation to become a natural fresh-keeping film; fresh The sandwiches are sterilized by irradiation, pre-cooled, put into the packaging container, and the packaging container is sealed; the mixed gas of carbon dioxide, nitrogen and carbon monoxide is filled into the packaging container, and the proportion of the mixed gas is 33% of carbon dioxide, 63.5% of nitrogen, and 3.5% of carbon monoxide; control The humidity in the packaging container is 84%, and the air filling port is closed. Use 49ml of the above mixed gas per 100g sandwich, and maintain the balance of internal and external air pressure; the packaging container is boxed, double-layered, the outer layer is kraft paper, the inner layer is nano-scale polyolefin-based film, and the inner wall of the inner layer is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com