Preparation method of nitrogen-phosphorus double-doped hollow carbon nanotube

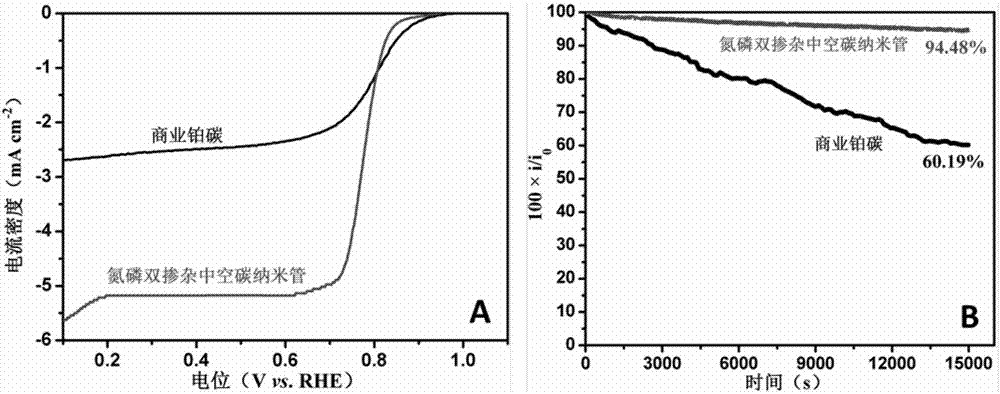

A carbon nanotube, double doping technology, applied in chemical instruments and methods, electrical components, circuits, etc., can solve the problems of ineffective utilization of the inner wall and uneven distribution of nitrogen elements in carbon nanotubes, and increase the reactive sites. , low cost, high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

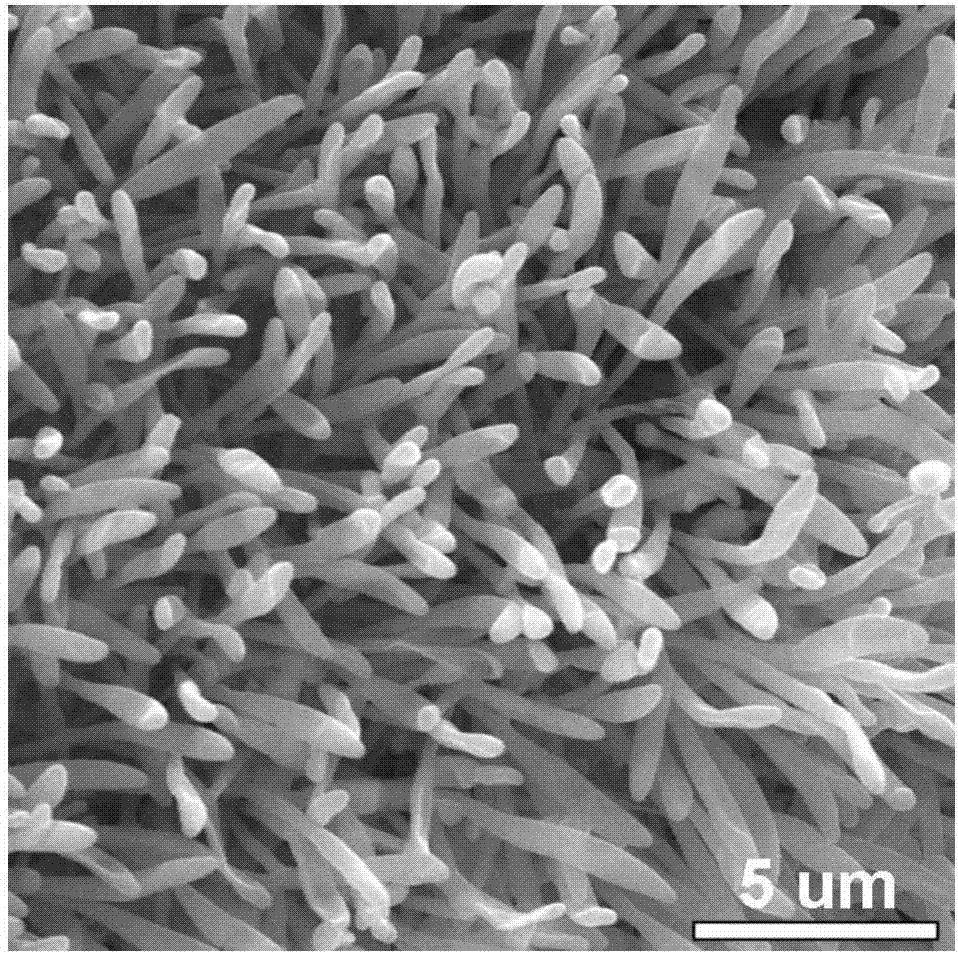

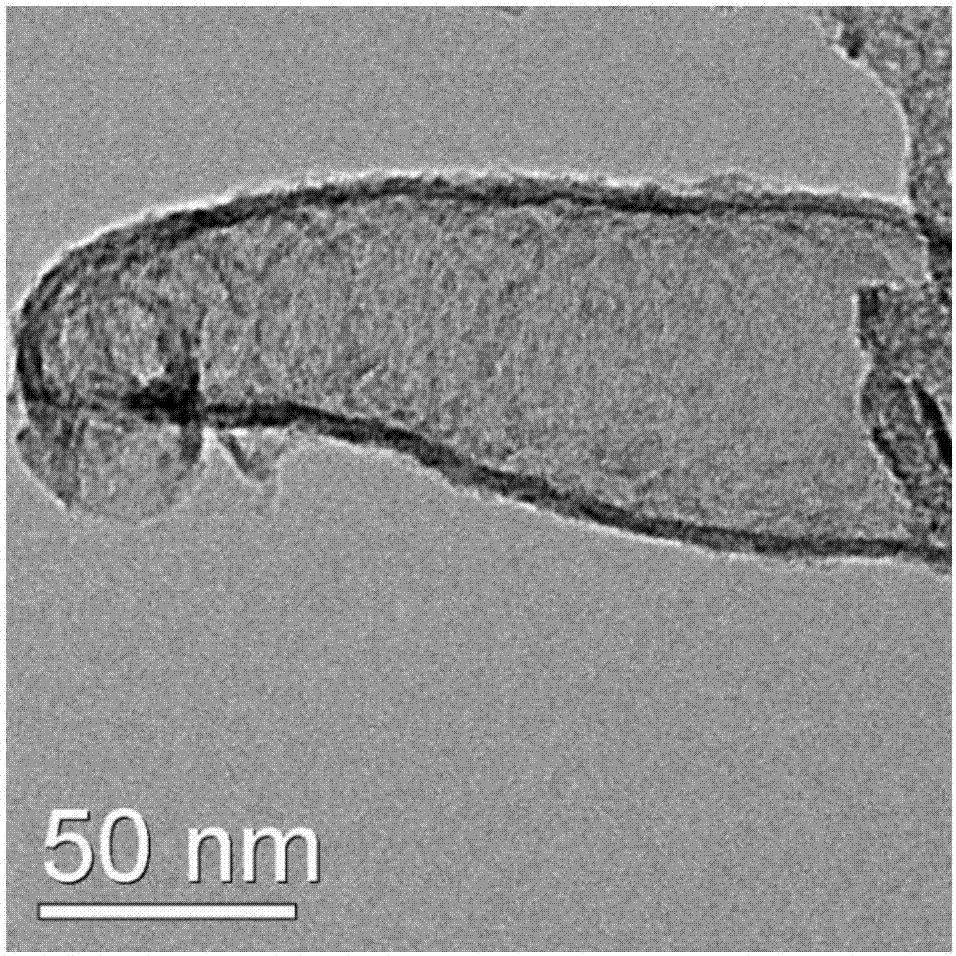

[0027] A method for preparing nitrogen-phosphorus double-doped hollow carbon nanotubes, the operation is as follows:

[0028] (1) Soak the nickel foam in hydrogen peroxide with a mass concentration of 30%, while maintaining the temperature at 60°C for heat treatment for 10 hours, so that the surface of the nickel-based material is oxidized to generate nickel hydroxide, and then the amino trimethylene phosphonic acid resin is tiled Put it on a porcelain boat, and cover it with the nickel-based material obtained after heat treatment;

[0029] (2) Transfer the material boat obtained in step (1) into a tube furnace, keep the heating rate in a nitrogen atmosphere at 5°C / min and heat to 850°C for 0.5 hour heat treatment, the compound in the material boat is provided by thermal decomposition Gaseous carbon source, nitrogen source and phosphorus source, phosphating reaction occurs on the surface of the nickel-based material and nickel phosphide is generated, and the cylindrical nickel...

Embodiment 2

[0032] A method for preparing nitrogen-phosphorus double-doped hollow carbon nanotubes, the operation is as follows:

[0033] (1) Soak the nickel sheet in hydrogen peroxide with a mass concentration of 15%, while maintaining the temperature at 40°C for 6 hours, so that the surface of the nickel-based material is oxidized to form nickel hydroxide, and then spread the cyanamide phosphoric acid resin on the porcelain boat On, and cover the nickel-based material obtained after heat treatment;

[0034] (2) Transfer the material boat obtained in step (1) into a tube furnace, maintain a heating rate of 5°C / min in an inert atmosphere nitrogen and heat it to 700°C for heat treatment for 3.5 hours, and the compound in the material boat is thermally decomposed Provide gaseous carbon source, nitrogen source and phosphorus source, phosphating reaction occurs on the surface of the nickel-based material and nickel phosphide is generated, and the cylindrical nickel phosphide catalyzes the gro...

Embodiment 3

[0037] A method for preparing nitrogen-phosphorus double-doped hollow carbon nanotubes, the operation is as follows:

[0038] (1) Soak the nickel foil in hydrogen peroxide with a mass concentration of 23%, while maintaining the temperature at 80°C for heat treatment for 2 hours to oxidize the surface of the nickel-based material to generate nickel hydroxide, and then spread (triphenylphosphine) acetonitrile Put it on a porcelain boat, and cover it with the nickel-based material obtained after heat treatment;

[0039](2) Transfer the material boat obtained in step (1) into a tube furnace, keep the heating rate in an inert atmosphere argon at 5°C / min and heat to 1200°C for heat treatment for 2.0 hours, the compound in the material boat is heated Decompose to provide gaseous carbon source, nitrogen source and phosphorus source. Phosphating reaction occurs on the surface of nickel-based materials and nickel phosphide is generated. Cylindrical nickel phosphide catalyzes the growth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com