Preparation method of polybutadiene with greatly adjustable microstructure content and crystallinity

A technology of polybutadiene and microstructure, which is applied in the field of preparation of polybutadiene with large adjustment of microstructure content and crystallinity, can solve the problems that the microstructure and aggregated structure cannot be greatly adjusted, and achieve rich variety , the system is pure, and the effect of reducing the difficulty of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Under the protection of nitrogen, add MoCl to the dry catalyst reaction flask in sequence 5 , n-BuOH and toluene, where n-BuOH / MoCl 5 2 / 1, react at 25°C for 24h to obtain the main catalyst MoCl for butadiene polymerization 3 (OC 4 h 19 ) 2 . MoCl 3 (OC 8 h 17 ) 2 with AlEt 3 Mix well according to Al / Mo=2, 4, 6 respectively.

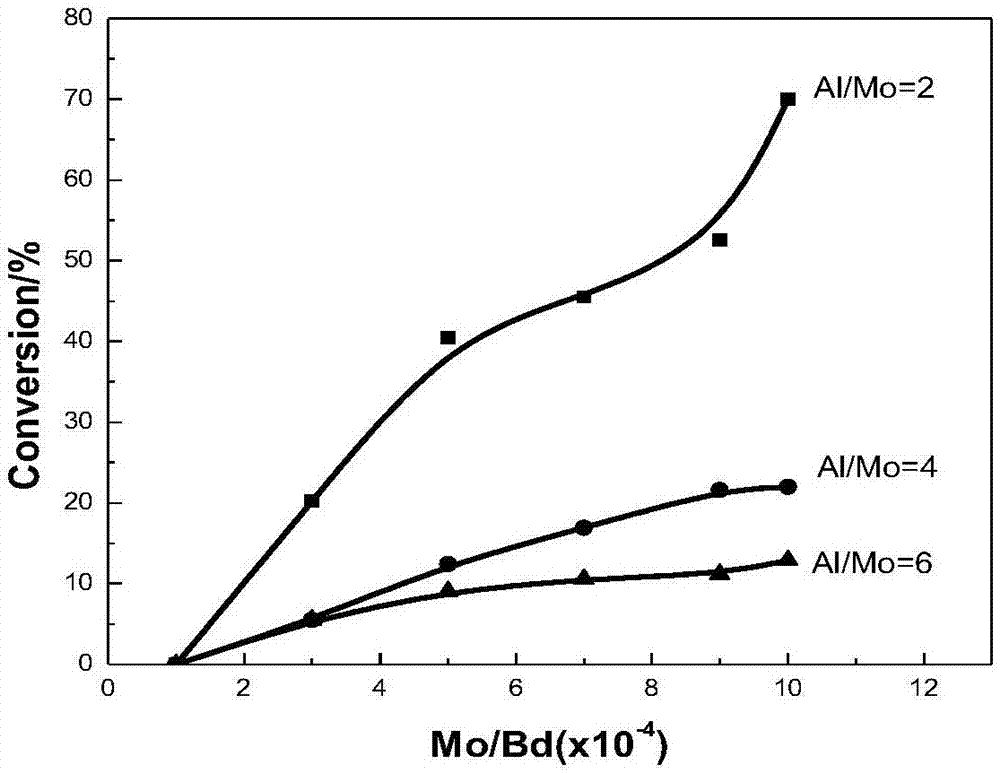

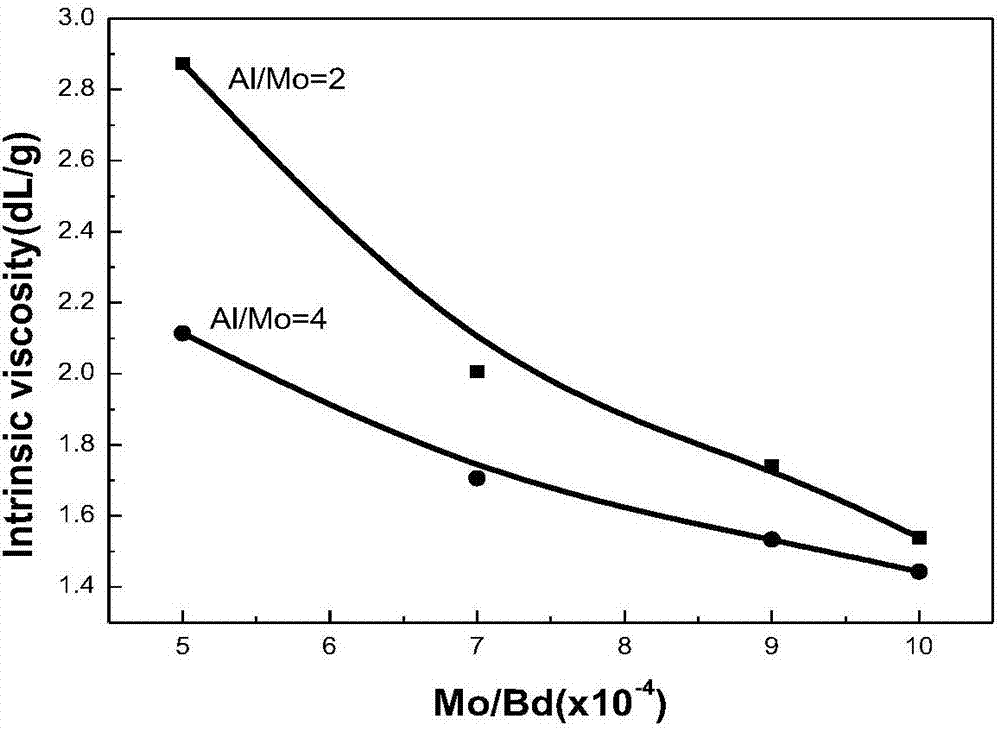

[0036] Under nitrogen protection, 30 ml of a toluene solution of butadiene monomer was added to a dry and sealed 50 ml reaction bottle, wherein the concentration of butadiene was 1.4 g / 10 ml. Add MoCl 3 (OC 8 h 17 ) 2 with AlEt 3 The reaction solution was polymerized at 30°C. After 6 hours of polymerization reaction, the ethanol solution containing 1% anti-aging agent 264 was used to terminate, and the ethanol was condensed to obtain polybutadiene. For polymerization conditions and polymer test results see figure 1 and figure 2 .

[0037] Such as figure 1 As shown, the monomer conversion gradually increased with the increase o...

Embodiment 2

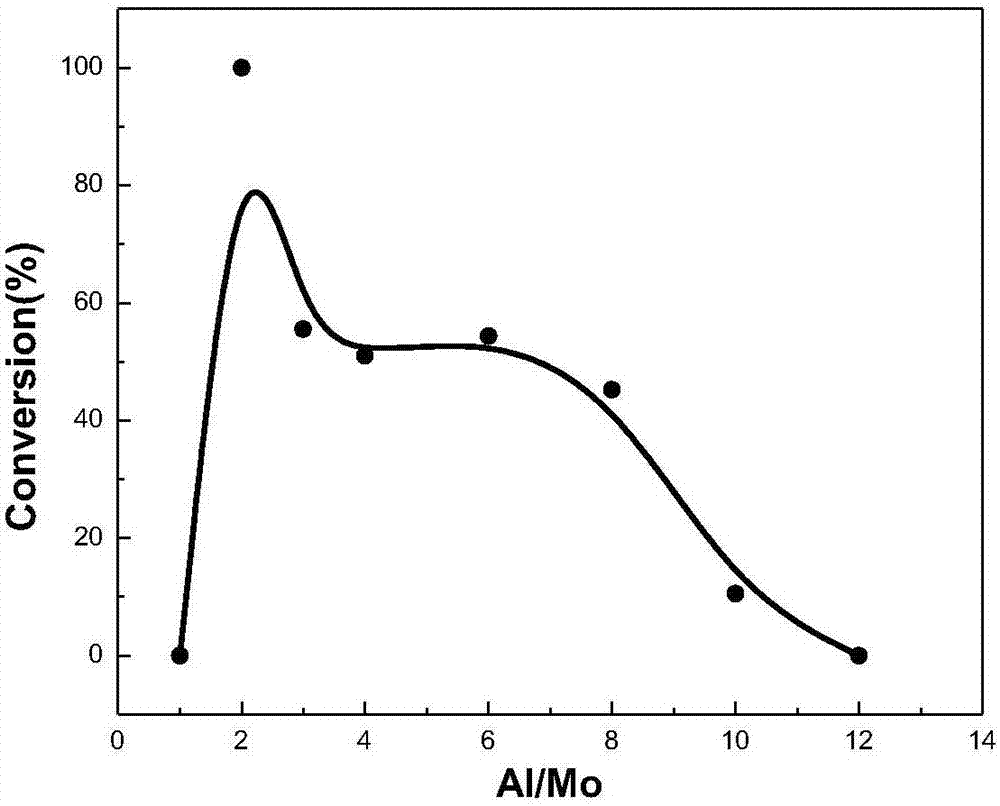

[0039] According to the method preparation MoCl of embodiment 1 3 (OC 4 h 9 ) 2 Catalyst, in multiple airtight containers vacuumized and filled with nitrogen, quantitative MoCl 3 (OC 8 h 17 ) 2 with variable AlEt 3 Mix well, where Mo / Bd molar ratio is 1×10 -3 , and the polymerization temperature was 30°C. Polymerization was carried out according to the polymerization method of Example 1 and the polybutadiene obtained in this example was characterized. In addition, the detection of the microstructure uses a tablet method, preferably measured on a Vertex-70FTIR infrared spectrometer from Bruker Company. The thermal analysis data was measured by a German NETZSCH DSC204 differential scanning calorimeter, liquid nitrogen was used as the refrigerant, and the measurement temperature range was -120-250°C. The experiments all used secondary scanning, and the heating and cooling rate was 10°C / min.

[0040] image 3 At the polymerization temperature of 30°C, MoCl 5 ·n-BuOH / Al...

Embodiment 3

[0052] According to the method of embodiment 2, difference is that polymerization temperature is respectively 60 ℃, 30 ℃ and 0 ℃; Test method has increased GPC, and the preferred gel permeation chromatography (U.S. Waters1515 type) of molecular weight and molecular weight distribution is measured, wherein GPC With HT4 (molecular weight range 5×10 3 ~6×10 5 ), HT5 (molecular weight range 5×10 4 ~4×10 6 ), HT6 (molecular weight range 2×10 5 ~1×10 7 ) three separation columns. Molecular weight and molecular weight distribution data were measured using tetrahydrofuran as the mobile phase at a flow rate of 1 ml / min. The molecular weight distribution of the polymer is characterized by the number average molecular weight (Mn) and weight average molecular weight (Mw) of the polymer with styrene as the internal standard and the ratio of the weight average molecular weight to the number average molecular weight (Mn / Mw).

[0053] Figure 7 is the effect of temperature on monomer c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com