Core-shell type molecularly imprinted polymer capable of recognizing erythrosine and preparation method

A molecular imprinting, polymer technology, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., to achieve fast and accurate specific identification, overcome mass transfer, overcome slow kinetics effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

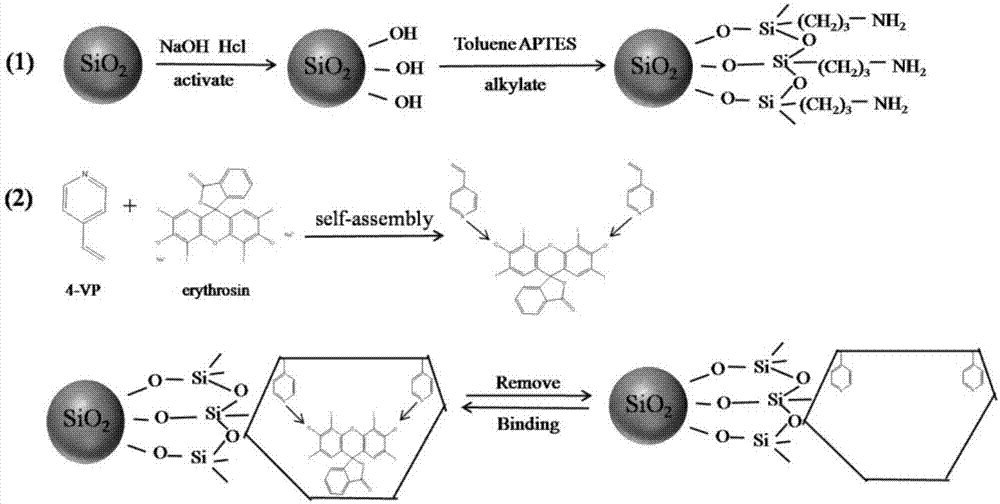

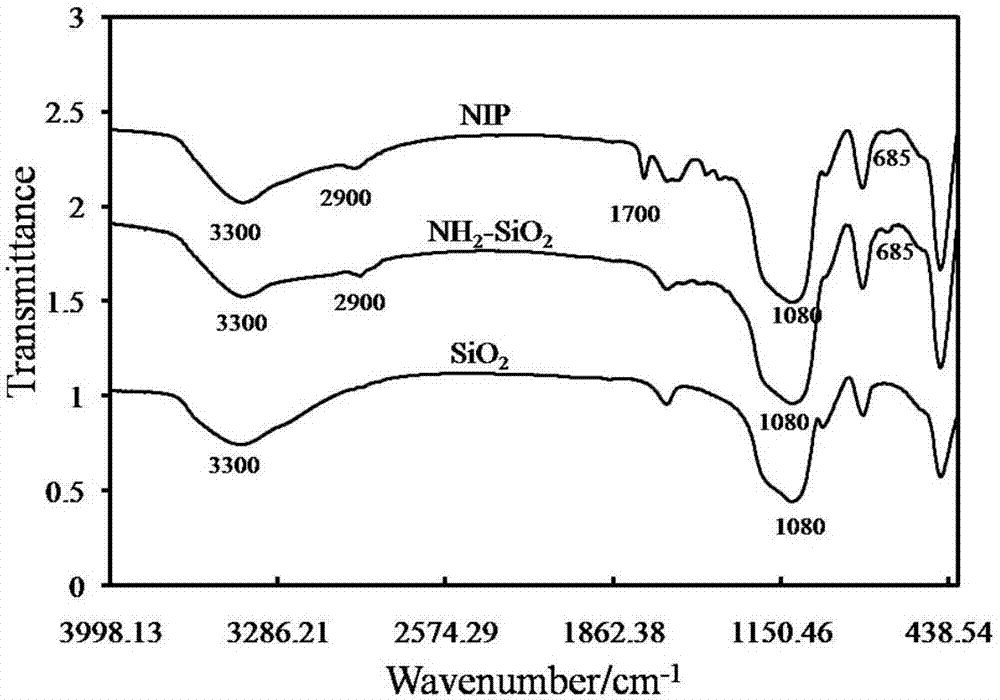

[0027] Example 1: Silica surface amination modification

[0028] Accurately weigh 1g of solid sodium hydroxide, add 100mL of ultrapure water to dissolve, and prepare a sodium hydroxide aqueous solution with a concentration of 0.25 moL / L; accurately measure 6.18mL of hydrochloric acid, add 93.82mL of ultrapure water to dilute, and prepare a concentration of 2moL / L of hydrochloric acid aqueous solution.

[0029] (1) Activation of silica: Accurately weigh 10g of silica microspheres into a 250mL round bottom flask, add 100mL of NaOH (0.25 mol / L), place on a magnetic stirrer, stir and corrode at room temperature for 30 min, then Eluted with ultrapure water; the alkali-treated silica was then refluxed with 100 mL, 2 moL / L HCl at 90°C for 8 h, and then eluted with ultrapure water until neutral and dried.

[0030] (2) Silica surface amination: Weigh 10 g of activated silica into a 250 mL round bottom flask, add 100 mL of toluene, and then add 5 mL of 3-aminopropyltriethoxysilane (A...

example 2

[0031] Example 2: Preparation of erythrosine molecularly imprinted polymers and non-molecularly imprinted polymers

[0032] Accurately weigh 0.2375mmoL of erythrosine and dissolve it in 50 mL of methanol:water=4:1 (v / v), and add the functional body 4-VP (0.95mmoL) into the solution, stir and incubate at room temperature for 2 h, then Surface-modified silica (1 g), cross-linking agent EGDMA (4.75 mmoL), and initiator AIBN (0.014 g) were added in sequence, mixed by ultrasonic waves, then put into a round-bottomed flask, stirred magnetically at room temperature for 10 min, and then added Install a three-way glass tube, and pass through nitrogen (60min) to remove oxygen.

[0033] Place the airtight container containing the above reaction solution on a magnetic stirrer, adjust the appropriate speed and continue to stir, heat in an oil bath at 70°C, take it out after 24 hours of reaction, and the reaction solution polymerizes to prepare the erythrosine molecularly imprinted polymer ...

example 3

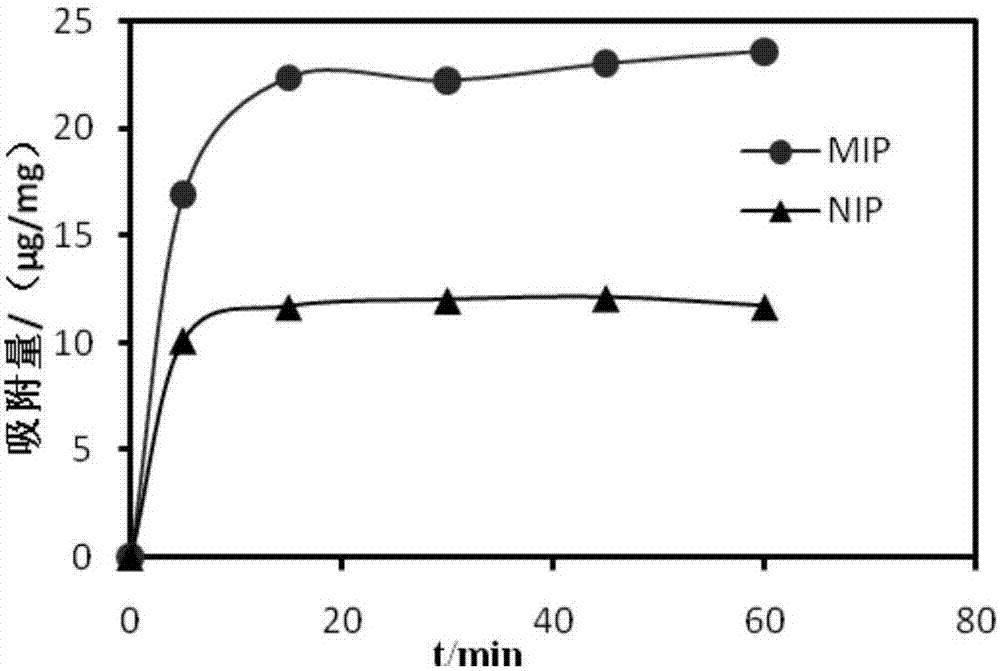

[0035] Example 3: Adsorption kinetics experiment

[0036] Accurately weigh 7.2 mg of erythrosine solid sample, dissolve it in 12 mL of ultrapure water, and mix it by ultrasonic to prepare an erythrosine aqueous solution with a concentration of 600 μg / mL. Take 10 4mL centrifuge tubes and mark the serial number, then weigh 10 mg of the prepared MIP microspheres and NIP microspheres and place them in them, 5 tubes for each of the two types of microspheres. Add 1mL of 600 μg / mL erythrosin aqueous solution to each centrifuge tube, ultrasonically mix, and then stand at room temperature for adsorption. Take samples when the adsorption time is 5, 15, 30, 45, and 60 min, centrifuge to get the supernatant, measure its absorbance at 533nm with an ultraviolet-visible spectrophotometer (Uv-vis), and calculate it by the formula (1) The adsorption capacity (Q) was observed to observe the change rule of the adsorption capacity with the adsorption time.

[0037]

[0038] Among them, Q is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com