Preparation method of sulfonated poly (arylene sulfide sulfone) / polyimide block type proton exchange membrane material

A technology of sulfonated polyarylene sulfide and polyimide block, which is applied in the field of fuel cells, can solve the problems of affecting the service efficiency and life of the battery, easy swelling or even dissolution, and poor dimensional stability, so as to overcome the extremely easy swelling or Effects of dissolution, reduction of water absorption, and improvement of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

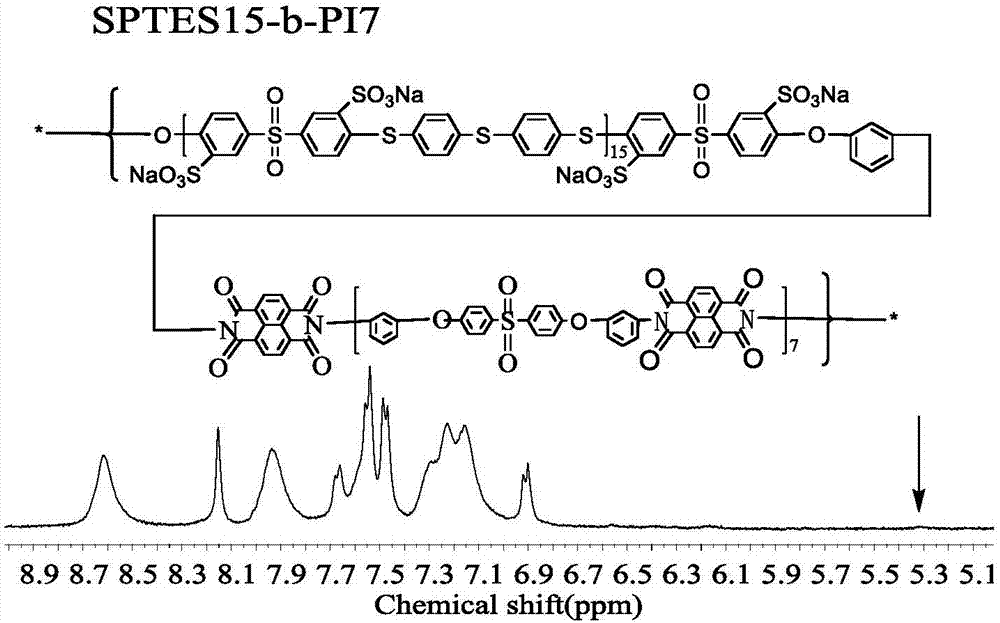

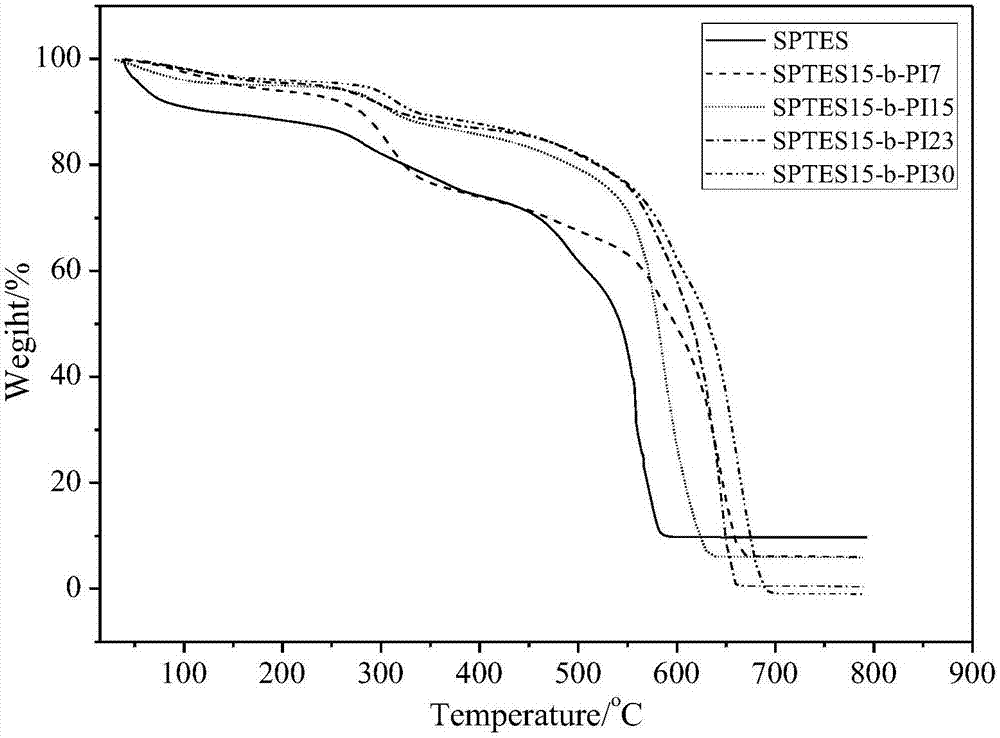

[0040] Synthesis and preparation of block-type sulfonated polyarylene sulfide sulfone-polyimide (SPTES15-b-PI7)

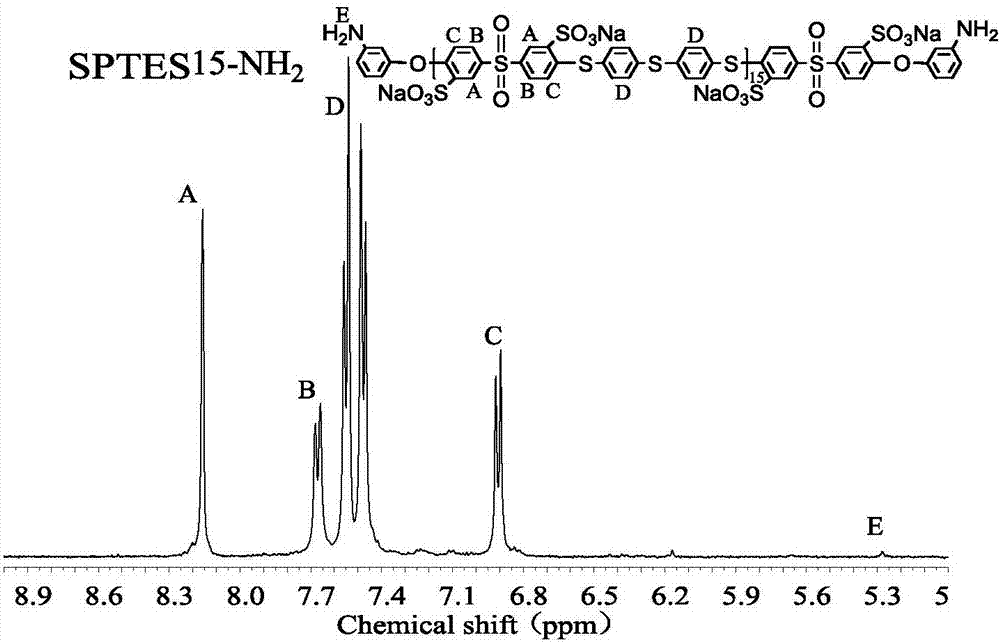

[0041] (1) Preparation of SPTES15-NH end-capped by an amino-blocking agent with a degree of polymerization of 30 2 The reaction process is as follows, 4.58g (10mmol) SDFDPS, 2.439g (9.756mmol) TBBT, and 100g sulfolane solvent are added to a dry there-necked flask, and 3.312g (24mmol) anhydrous potassium carbonate is added as a catalyst, magnetically stirred, Under the protection of nitrogen, stir at room temperature for 30min; then raise the temperature to 100°C, react for 1h; then raise the temperature to 160°C, and react at constant temperature for 6h; cool to room temperature, pour 480ml of methanol: acetic acid (v:v=10:1) mixture to precipitate , suction filtration, to obtain white massive polymer; wash three times with methanol aqueous solution (v methanol:v deionized water=3:1), use methanol as solvent, Soxhlet extraction 48h (Soxhlet extraction is a known te...

Embodiment 2

[0056] Synthesis and preparation of block-type sulfonated polyarylene sulfide sulfone-polyimide (SPTES15-b-PI15)

[0057] (1) Preparation of SPTES15-NH end-capped by an amino-blocking agent with a degree of polymerization of 30 2 , the preparation process is as described in Example 1.

[0058] (2) The process of preparing the anhydride-terminated PI15 hydrophobic segment with a degree of polymerization of 30 is as follows, weigh 2.6818g (10mmol) 1,4,5,8-naphthalene tetracarboxylic dianhydride, 4.0853g (9.446mmol) '-bis(3-aminophenoxy)-diphenylsulfone, and 62g of m-cresol solvent, were added to a 250ml three-necked flask, 1.2212g (10mmol) of benzoic acid was added, and 18ml of anhydrous toluene was used as a water-carrying agent. Water separator, condenser, magnetic stirring, under the protection of nitrogen, heat up to 80°C, react for 4h; heat up to 180°C, reflux for 12h; add 1.2916g (10mmol) isoquinoline, continue to react at 180°C for 12h; the reaction is completed, After ...

Embodiment 3

[0064] Synthesis and preparation of block-type sulfonated polyarylene sulfide sulfone-polyimide (SPTES15-b-PI23)

[0065] (1) Preparation of SPTES15-NH end-capped by an amino-blocking agent with a degree of polymerization of 30 2 , the preparation process is as described in Example 1.

[0066] (2) The process of preparing the anhydride-terminated PI23 hydrophobic segment with a degree of polymerization of 46 is as follows, weighing 2.6818g (10mmol) 1,4,5,8-naphthalene tetracarboxylic dianhydride, 4.2201g (9.7577mmol) 4,4 '-bis(3-aminophenoxy)-diphenyl sulfone, and 62g of m-cresol solvent were added to a 250ml three-necked flask, 1.2212g (10mmol) of benzoic acid was added, and 18ml of anhydrous toluene was used as a water-carrying agent. Water container, condenser, magnetic stirring, under nitrogen protection, heat up to 80°C, react for 4h; heat up to 180°C, reflux for 12h; add 1.2916g (10mmol) isoquinoline, continue to react at 180°C for 12h; After reaching room temperature,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com