Nutrient solution for plants cultured without soil

A plant nutrient solution and soilless cultivation technology, which is applied in the field of soilless cultivation plant nutrient solution, can solve the problems of plant growth rate, flowering number, fruiting rate, no improvement of nutrients, limited nutrients in nutrient solution, small buffer capacity, etc. problem, to achieve the effect of accelerating plant growth, promoting growth, and high fruiting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

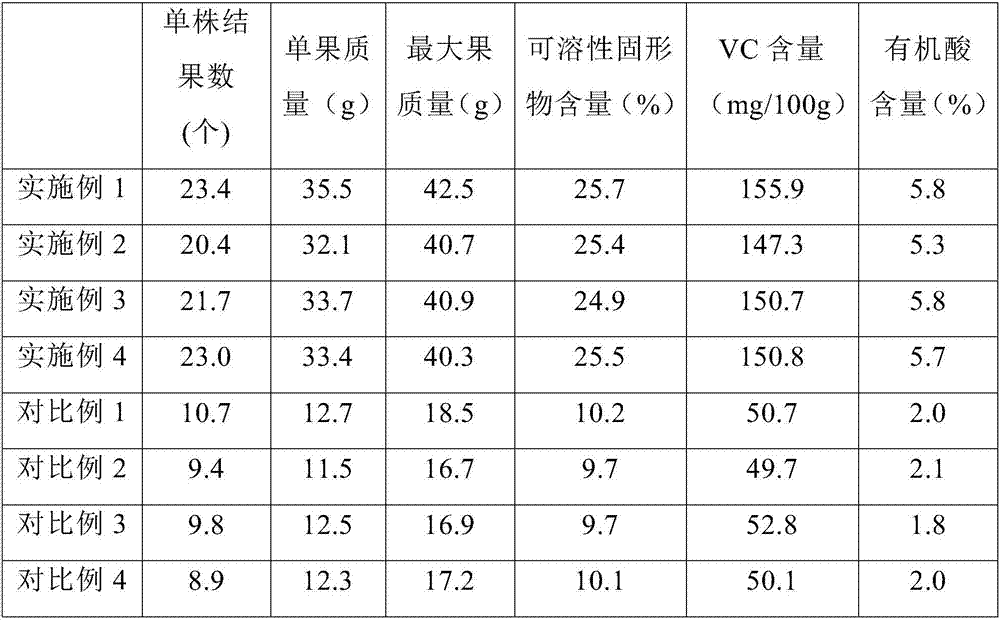

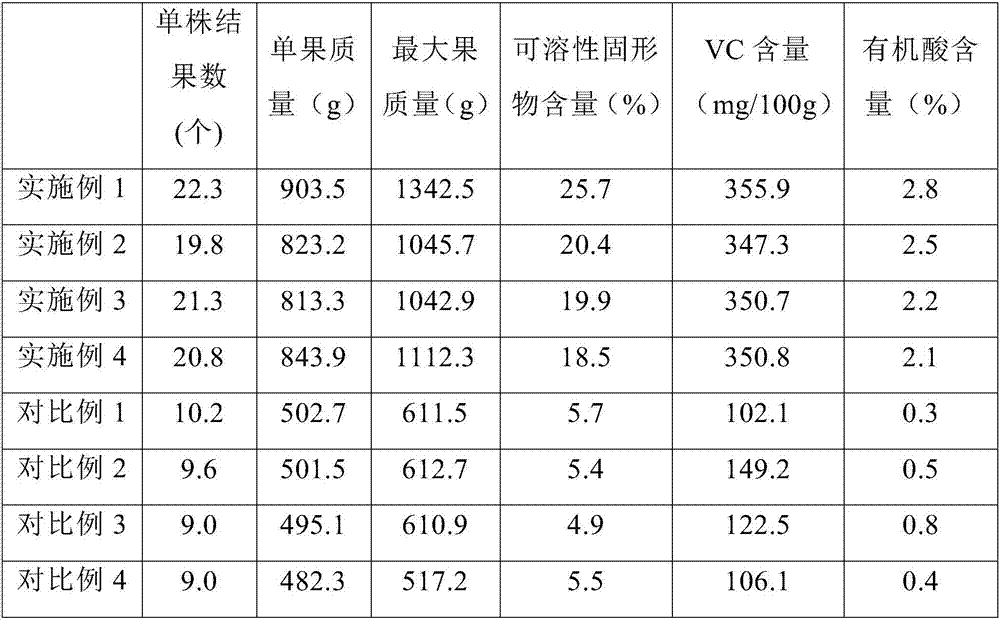

Examples

Embodiment 1

[0017] A nutrient solution for soilless cultivation plants, the nutrient solution comprises the following components in parts by weight: 5% sodium paeonol sulfonate, 3% magnesium stearate, 1% potassium magnesium phosphate, 1.2% sodium molybdate, copper sulfate 1.3%, potassium hydroxide 1.7%, sodium borate 2%, ammonium molybdate 2.5%, calcium nitrate 0.6%, urea 2.5%, ferrous sulfate 1.3%, naphthalene acetic acid 4%, glucose 3%, polyaspartic acid 2.8 %, EM agent 0.8%, Bacillus subtilis agent 1.2%, Pseudomonas fluorescens agent 2%, Trichoderma agent 6% and Beauveria bassiana agent 4%.

Embodiment 2

[0019] A nutrient solution for soilless cultivation plants, the nutrient solution includes the following components in mass percentage: 10% sodium paeonol sulfonate, 3% magnesium stearate, 1.2% potassium magnesium phosphate, 1% sodium molybdate, copper sulfate 2%, potassium hydroxide 1%, sodium borate 2%, ammonium molybdate 2%, calcium nitrate 1.0%, urea 2%, ferrous sulfate 2%, naphthalene acetic acid 2%, glucose 5%, polyaspartic acid 2.8 %, EM agent 0.9%, Bacillus subtilis agent 2%, Pseudomonas fluorescens agent 2%, Trichoderma agent 5% and Beauveria bassiana agent 5%.

Embodiment 3

[0021] A nutrient solution for soilless cultivation plants, the nutrient solution comprises the following components in mass percentage: 2% sodium paeonol sulfonate, 5% magnesium stearate, 1% potassium magnesium phosphate, 2% sodium molybdate, copper sulfate 1%, potassium hydroxide 2%, sodium borate 3%, ammonium molybdate 4%, calcium nitrate 0.5%, urea 3%, ferrous sulfate 1%, naphthalene acetic acid 7%, glucose 3%, polyaspartic acid 3 %, 0.7% of EM agent, 1% of Bacillus subtilis agent, 5% of Pseudomonas fluorescens agent, 8% of Trichoderma agent and 3% of Beauveria bassiana agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com