Extract of Rhus typhina fruit and preparation method thereof, and application of extract to fermentation production of genetic engineering products

A technology of extracts and fruits, applied in the field of agricultural product processing, can solve problems such as high cost, difficult quality control of genetic engineering products, high energy consumption induced by temperature, etc., and achieve the effects of reducing toxicity, saving fermentation costs, and efficient expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of RtSE

[0021] Put the fresh torch tree fruit in a cool and ventilated place at room temperature to dry in the shade, then air-dry at 60°C to a water content of 5% by weight, and mix the dried torch tree fruit with 20% ethanol aqueous solution by volume percentage, relative to 1kg of dry torch Tree fruit, the consumption of ethanol aqueous solution is 8L, obtains the material after mixing, and the material after described mixing is put in the round-bottomed flask and heats, and keeps refluxing 2 hours under slightly boiling state, after the material after reflux is cooled, hollow fiber Membrane filtration, the filtered material was centrifuged at 5000rpm for 30 minutes to obtain the clear liquid, and the clear liquid was placed in a rotary evaporator at 45°C to remove ethanol under reduced pressure and concentrated according to the ratio of 10:1, then passed through a 0.22μm Sterilize by filtration to obtain RtSE.

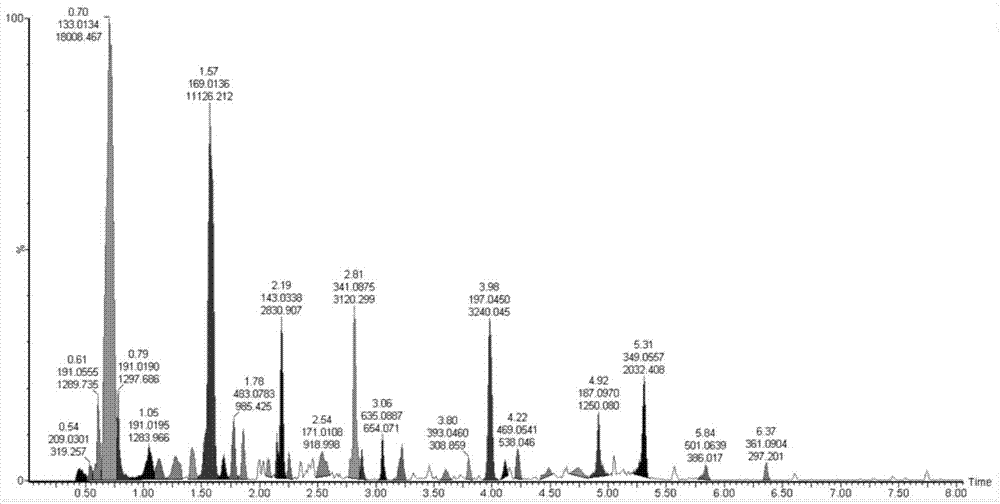

[0022] The obtained RtSE adopts Folin's...

Embodiment 2

[0026] Effects of RtSE on the ability of LacUV5-T7 system and LacI Q system to express foreign substances

[0027] In this example, Escherichia coli BL21 (DE3) was used as the host, and the LacUV5-T7 system used the pET28a plasmid; the LacI Q system used the pUC19 plasmid. The coding gene of exogenous target gene arginase was respectively inserted behind the Lac promoter of the two plasmids.

[0028] Plasmid pUC-ARG(LacI Q), pET28a-ARG(LacUV5-T7); strain E.coli BL21(DE3)[F-ompThsdS(r- B m- B )gal dcm(DE3)] was purchased from TransGen Biotech.

[0029] The RtSE prepared in Example 1 was used and pre-diluted with deionized water, so that the final concentrations of RtSE in each experimental system were 74.7, 18.7, 3.7 and 0.7 mg / L, respectively.

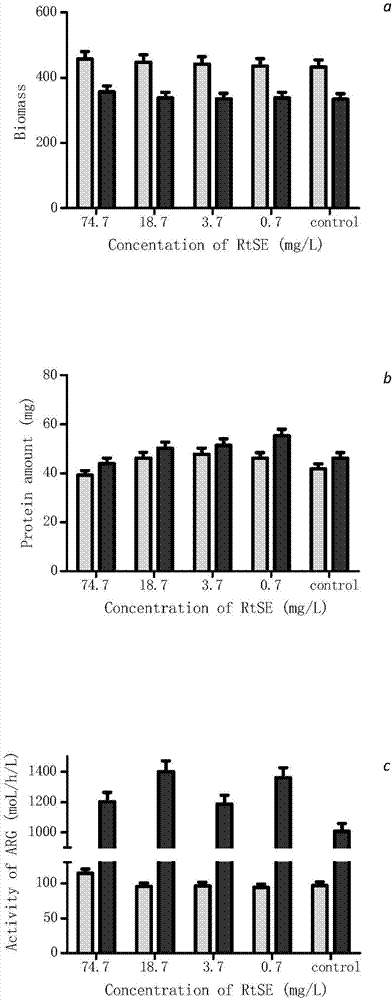

[0030] 2.1 Effect of RtSE on BL21(DE3)-pUC-ARG

[0031] Pick a single colony from the BL21(DE3)-pUC-ARG transformant and place it in LB liquid medium containing 100 μg / mL ampicillin, and place it overnight at 32° C. with a constan...

Embodiment 3

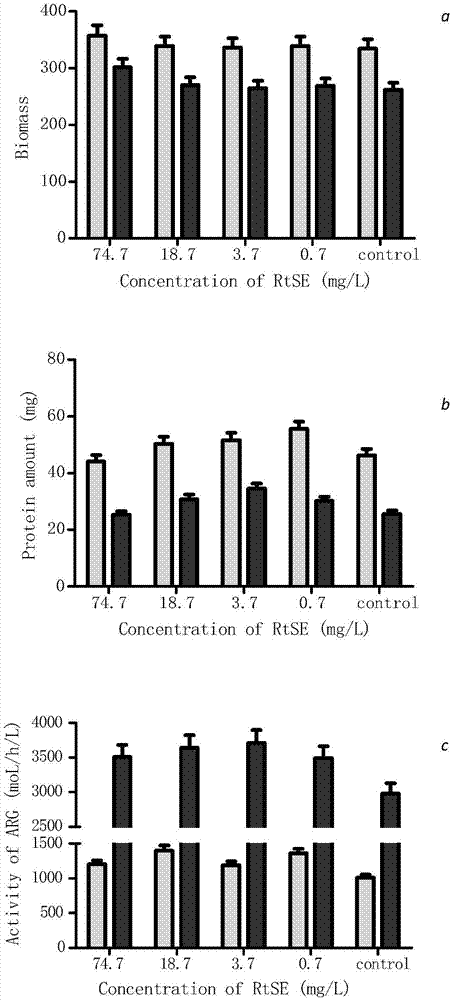

[0045] Effects of different concentrations of RtSE on the expression of exogenous protein activity induced by IPTG in LacUV5-T7 system.

[0046] The effects of different RtSE concentrations on the ability of LacUV5-T7 to express active arginase were investigated when 0.05mM IPTG was added to the fermentation broth.

[0047] Using the RtSE prepared in Example 1, the concentrations of RtSE in the fermentation system were 74.7mg / L, 18.7mg / L, 3.7mg / L and 0.7mg / L respectively.

[0048] The pET28a-ARG plasmid in Example 2 was used, and Escherichia coli BL21(DE3) was used as a host.

[0049] The biomass, protein amount, enzyme activity assay method and data statistical analysis method in Example 2 were used for statistics and analysis of data.

[0050] 3.1 Interaction between RtSE and IPTG

[0051] Pick a single colony from the BL21(DE3)-pET28a-ARG transformant and culture it in LB liquid medium containing 35μg / mL kanamycin 100mL at 37°C with a constant temperature shaker at 200rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com