Epoxy resin adhesive applicable to damp and underwater environments

A technology of epoxy resin and underwater environment, which is applied in the direction of epoxy resin glue, adhesive, carboxyl rubber adhesive, etc., and can solve the problems of undisclosed adhesive water resistance stability, poor adhesion between repair materials and wet interfaces, etc. , to achieve the effect of improving water resistance stability, increasing cross-linking density and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation method of the epoxy resin adhesive that is applicable to wet and underwater environment, comprises the following steps:

[0066] (1) Preparation method of component A:

[0067] Mix 100 parts by weight of bisphenol A type epoxy resin E51, 5 parts by weight of butyl glycidyl ether and 1 part by weight of carboxyl liquid nitrile rubber and stir evenly, then add 20 parts by weight of barium sulfate, 30 parts by weight of 800 mesh quartz powder and 10 parts by weight of cement, continue to stir evenly to make the system into a paste, and finally add 0.5 parts by weight of fumed silica in batches, and stir evenly;

[0068] (2) Preparation method of component B:

[0069] Mix 40 parts by weight of JA-1S curing agent, 2 parts by weight of catechol-modified ethylenediamine, 3 parts by weight of DMP-30 and 2 parts by weight of KH550 and stir evenly before discharging;

[0070] (3) Before use, component A and component B are mixed in a weight ratio of 3:1 and stir...

Embodiment 2

[0072] The preparation method of the epoxy resin adhesive that is applicable to wet and underwater environment, comprises the following steps:

[0073] (1) Preparation method of component A:

[0074] Mix 100 parts by weight of bisphenol A type epoxy resin E44, 10 parts by weight of 1,4-butanediol diglycidyl ether and 5 parts by weight of liquid polysulfide rubber JLY-121 and stir evenly, then add 5 parts by weight of calcium carbonate , 40 parts by weight of 400 mesh quartz powder and 20 parts by weight of cement, continue to stir evenly to make the system into a paste, finally add 1 part by weight of fumed silica in batches, and stir evenly;

[0075] (2) Preparation method of component B:

[0076] 40 parts by weight of 810 curing agent, 3 parts by weight of catechol-modified hexamethylenediamine, 6 parts by weight of dimethylaniline and 3 parts by weight of ND-42 are mixed and stirred evenly before discharging;

[0077] (3) Before use, component A and component B were mixed...

Embodiment 3

[0079] The preparation method of the epoxy resin adhesive that is applicable to wet and underwater environment, comprises the following steps:

[0080] (1) Preparation method of component A:

[0081] Mix 100 parts by weight of bisphenol A type epoxy resin E51, 20 parts by weight of benzyl glycidyl ether and 10 parts by weight of hydroxyl-terminated liquid silicone rubber HS-110 and stir evenly, then add 10 parts by weight of calcium carbonate, 10 parts by weight of sulfuric acid Barium, 40 parts by weight of 800 mesh quartz powder, continue to stir evenly to make the system into a paste, finally add 3 parts by weight of bentonite in batches, and stir evenly;

[0082] (2) Preparation method of component B:

[0083] Mix 50 parts by weight of 1085A curing agent, 1 part by weight of catechol-modified diethylenetriamine, 3 parts by weight of DMP30 and 4 parts by weight of KH570, stir evenly, and then discharge;

[0084] (3) Before use, component A and component B are mixed in a w...

PUM

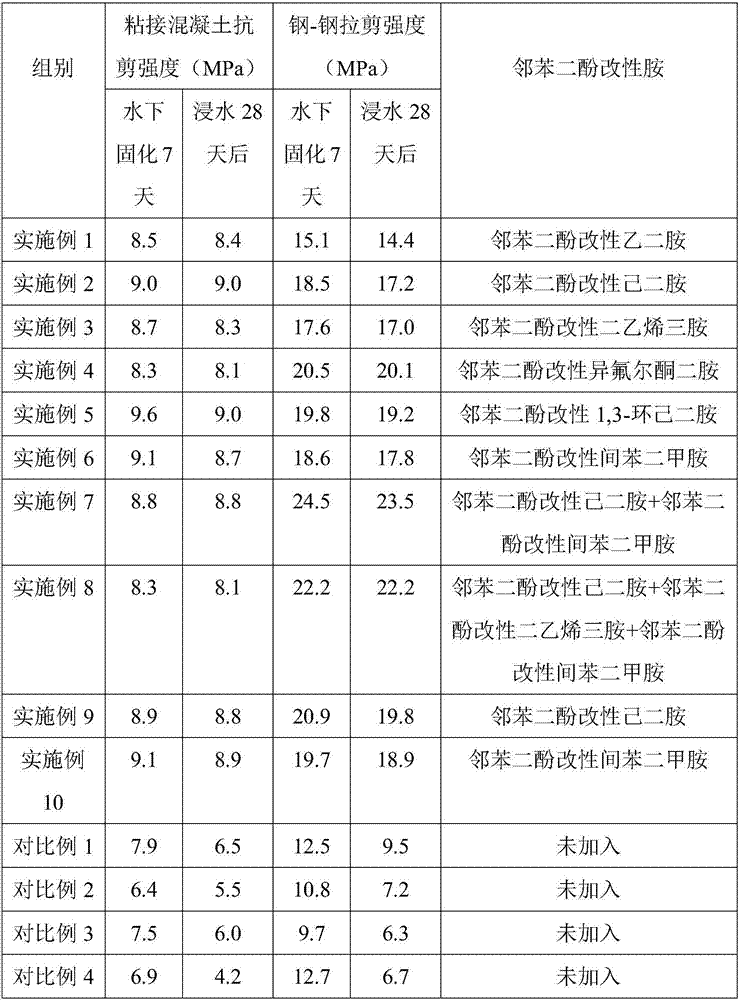

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com