Water-based paint composition and coating article

A water-based paint and composition technology, applied in the field of coated articles and water-based paint compositions, can solve the problem of oily dirt being unable to obtain sufficient anti-fouling properties, etc., and achieve excellent anti-fouling and decontamination properties, excellent water and oil repellency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0182] Hereinafter, the present invention will be described concretely with reference to examples, comparative examples, and test examples. However, these descriptions do not limit the present invention.

[0183] Hereinafter, unless otherwise specified, parts or % represent parts by weight or % by weight.

[0184] The properties were determined as follows.

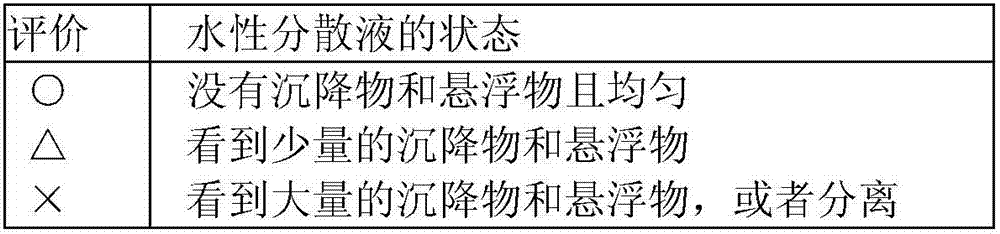

[0185] polymer stability

[0186] The aqueous dispersion prepared in the production example was left to stand at room temperature for one week, and the stability was visually evaluated.

[0187]

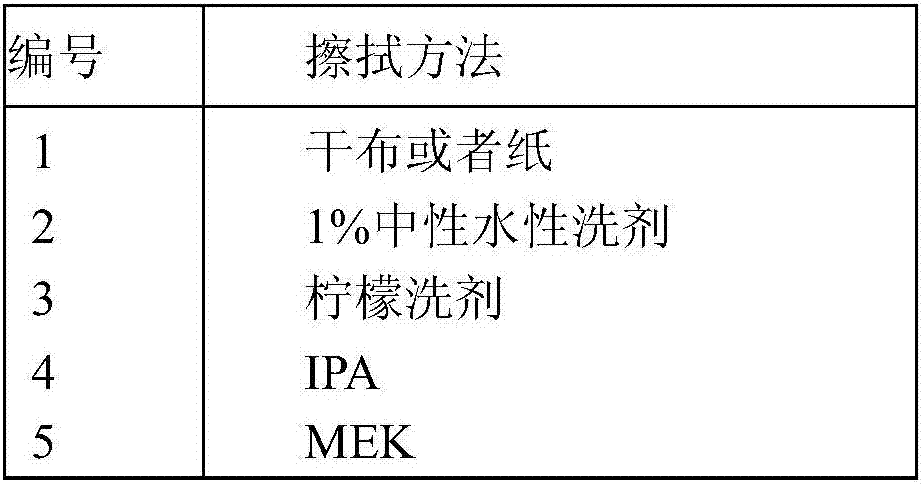

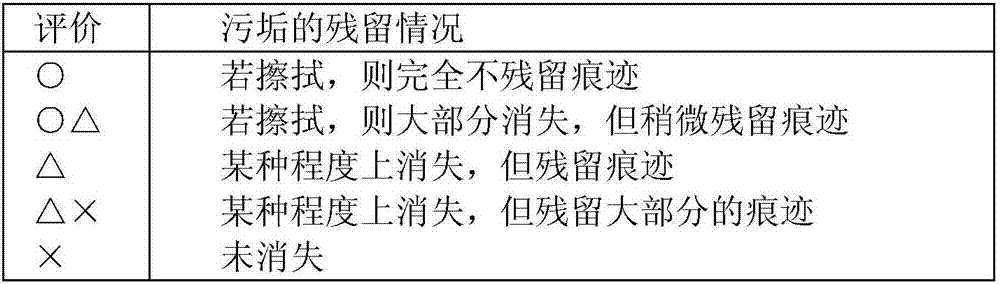

[0188] Antifouling test

[0189] The antifouling test was carried out with reference to ASTM (American Society for Testing and Materials: American Society for Testing and Materials standard) D6758-00 and JG / T304-2011. Dirt was attached to the sample-coated PET film using water-based whiteboard pens (ZEBRA blue and red) and oil-based markers (Sharpie blue and black). After 10 minutes, wipe with various wiping methods i...

manufacture example 1

[0196] In a 500ml reaction flask, make CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOCH=CH 2 (n=2.0) (C6SFA) 15g, methyl methacrylate 28g, butyl acrylate 22g, hydroxyethyl acrylate 27g, methacrylic acid 3g, methacrylate-3-chloro-2-hydroxypropyl 0.5g, glycerin 0.5 g of methacrylate was dissolved in 150 g of 2-propanol, and after nitrogen substitution in the reaction flask, a solution of 0.4 g of azobisisobutyronitrile and 9 g of water was added, heated to 80° C., and reacted for 20 hours. Then, neutralization was performed, 150 g of pure water was added, and 2-propanol was distilled off at 60 degreeC with stirring, and the aqueous dispersion liquid was obtained. The solid content was adjusted to 40%, and the composition of the polymer was basically the same as that of the loaded monomer.

manufacture example 2

[0198] Add 150 g of pure water, 3 g of alkyl sulfonate, and 3.0 g of polyoxyethylene alkyl ether into a 500 ml reaction flask, and after nitrogen substitution, add 2,2-azobis(2-amidinopropane) dihydrochloride A solution of 0.4g of salt and 9g of water, heated to 80°C, mixed slowly and dropwise added CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOCH=CH 2 (n=2.0) 5 g of (C6SFA), 32 g of methyl methacrylate, 37 g of butyl acrylate, 21 g of hydroxyethyl acrylate, and 3 g of methacrylic acid. After completion of the dropwise addition, it was allowed to react for 20 hours to obtain an aqueous dispersion. The solid content was adjusted to 40%, and the composition of the polymer was basically the same as that of the loaded monomer.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap