Preparation method and application of crumpled graphite phase carbon nitride

A graphitic carbon nitride, wrinkle technology, applied in chemical instruments and methods, nitrogen compounds, nitrogen and non-metallic compounds, etc., can solve problems such as low activity, improve electronic structure, enhance photocatalytic performance, and enhance photocatalysis performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

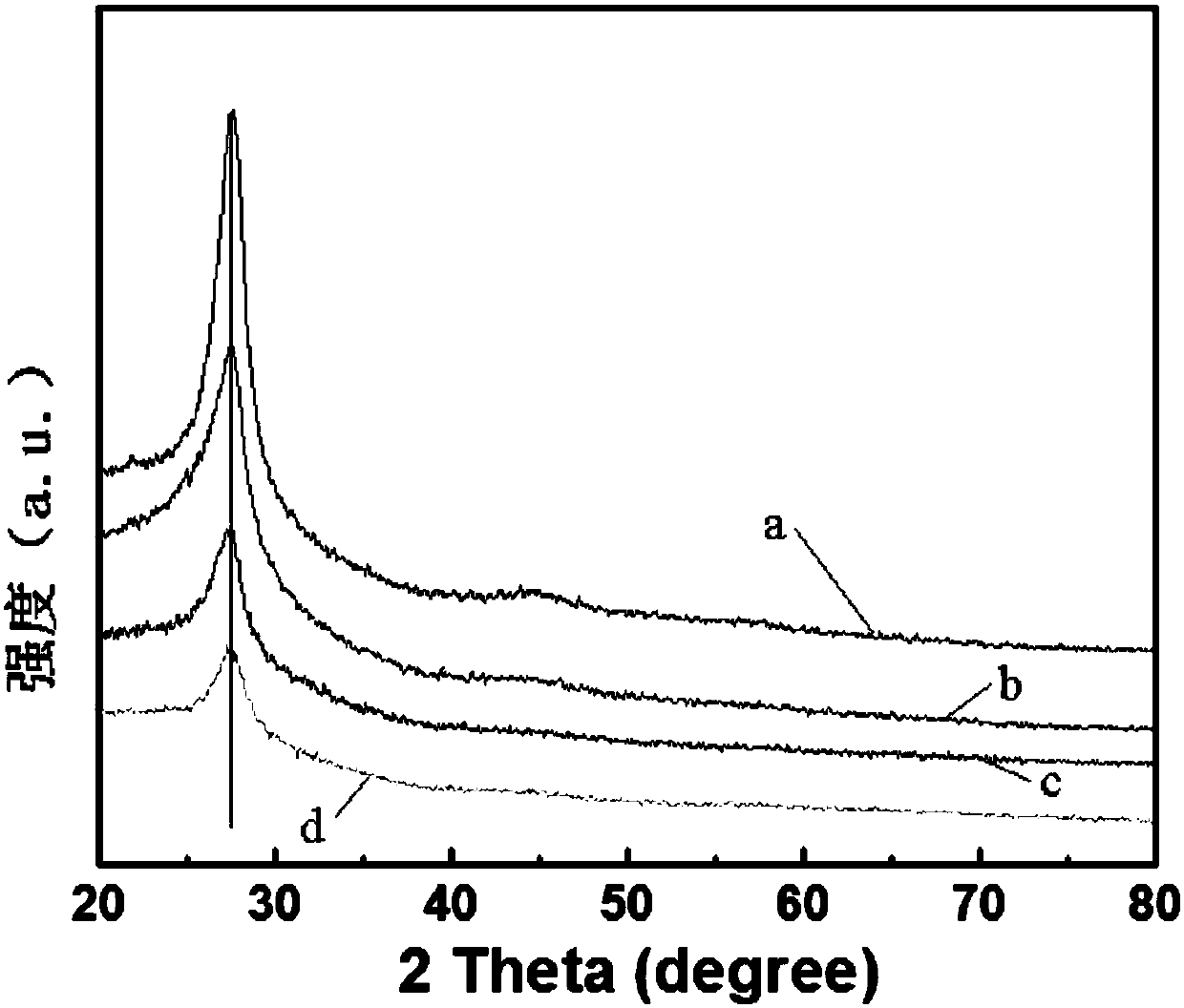

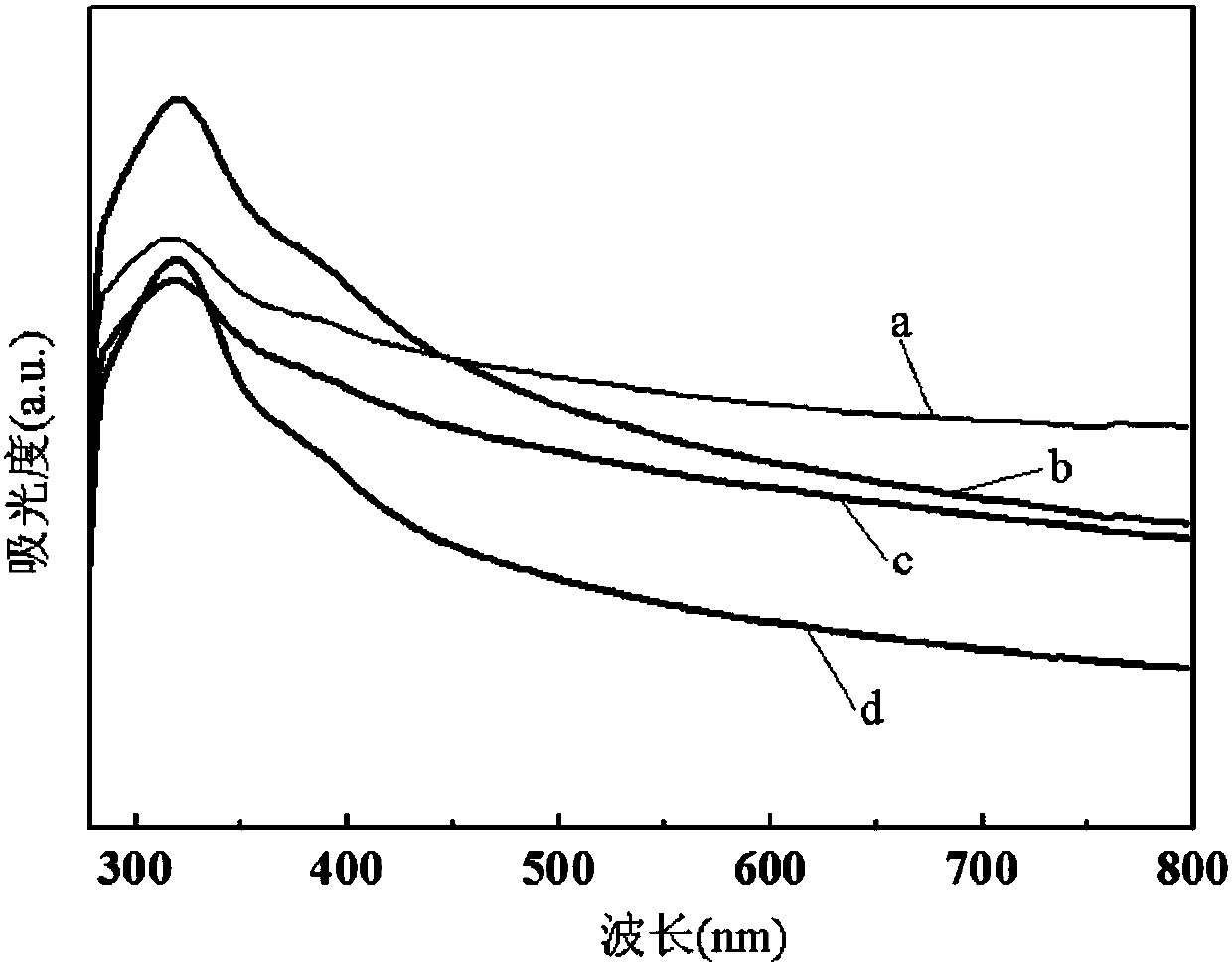

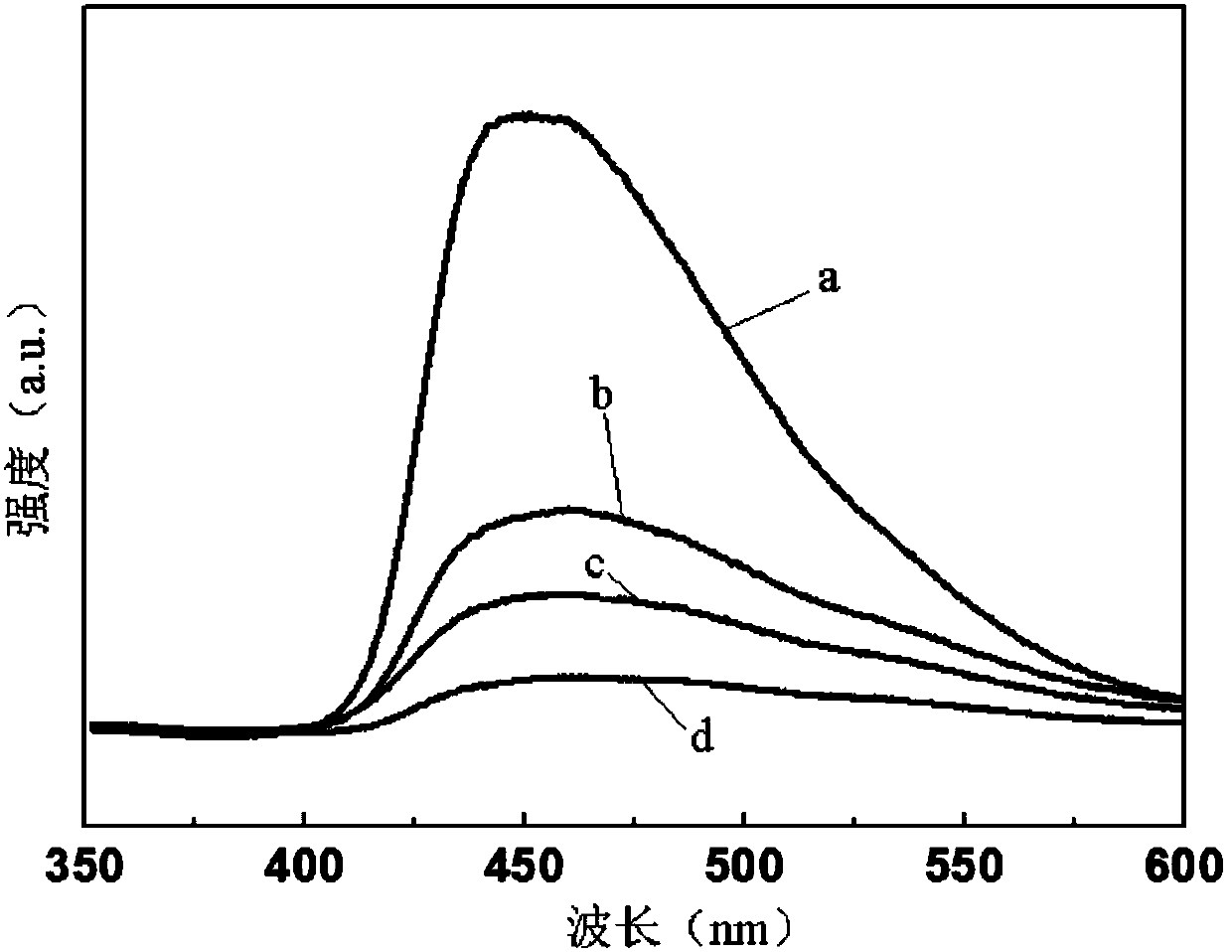

[0020] Embodiment 1: This embodiment is a method for preparing carbon nitride with a wrinkled graphite phase, and the specific process is as follows:

[0021] 1. Put melamine in a single-necked flask, add absolute ethanol, ultrasonically disperse for 2-3 minutes, then add glyoxal aqueous solution and ultrasonically disperse for 10-15 min, place the single-necked flask on a magnetic heating stirrer, and place the bottle of the single-necked flask The mouth of the condenser is connected to the condenser tube, and the other end of the condenser tube is opened, and condensed and refluxed in an oil bath at 80°C to 85°C for 1h to 1.5h, and the product obtained in the single-necked flask is dried at 60°C for 12h to 14h to remove the reaction solvent ethanol; The quality of described melamine and the volume ratio of dehydrated alcohol are 1g:(5mL~6mL); The concentration of described glyoxal aqueous solution is 8.8mol / L; In described glyoxal aqueous solution, glyoxal and melamine The m...

specific Embodiment approach 2

[0024] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, condense and reflux in an oil bath at 80° C. for 1 hour. Others are the same as the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the volume ratio of the mass of melamine described in step one to absolute ethanol is 1g:5mL. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com