Preparation method of anti-dazzle porous composite film and anti-dazzle glass using composite film

A porous composite film and composite film technology, applied in chemical instruments and methods, silicon compounds, silicates, etc., can solve the problem of incompatibility between anti-glare and light transmittance, reduce the overall strength of the glass substrate, and affect the sensory experience of users, etc. problems, to achieve the effect of improving the viewing experience, stable response, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

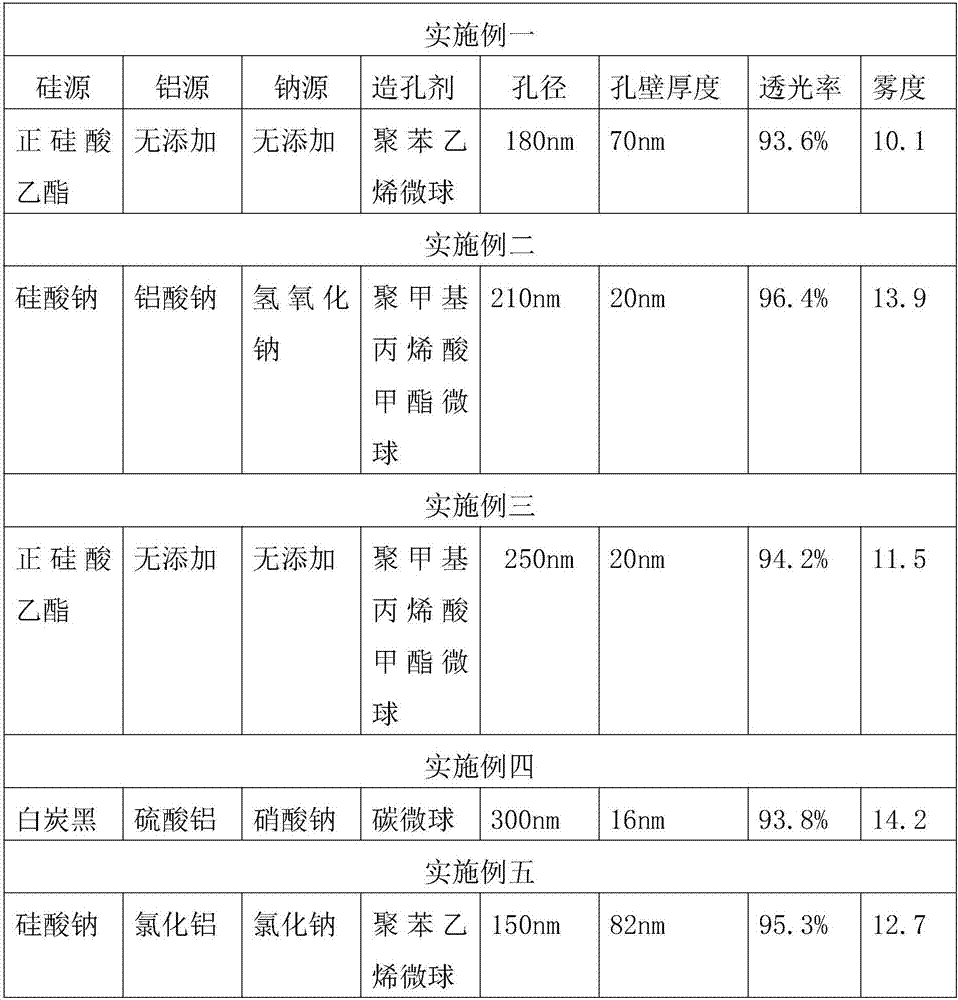

Embodiment 1

[0030] This example discloses a method for preparing an anti-glare porous composite film, the preparation process of which is as follows:

[0031] (1) Add 0.8ml of concentrated ammonia water, 17.2ml of tetraethyl orthosilicate, and 55ml of deionized water in sequence in the reaction bottle, react at room temperature for 2 hours, seal up after the reaction, and age for 12 hours to obtain a silicate sol;

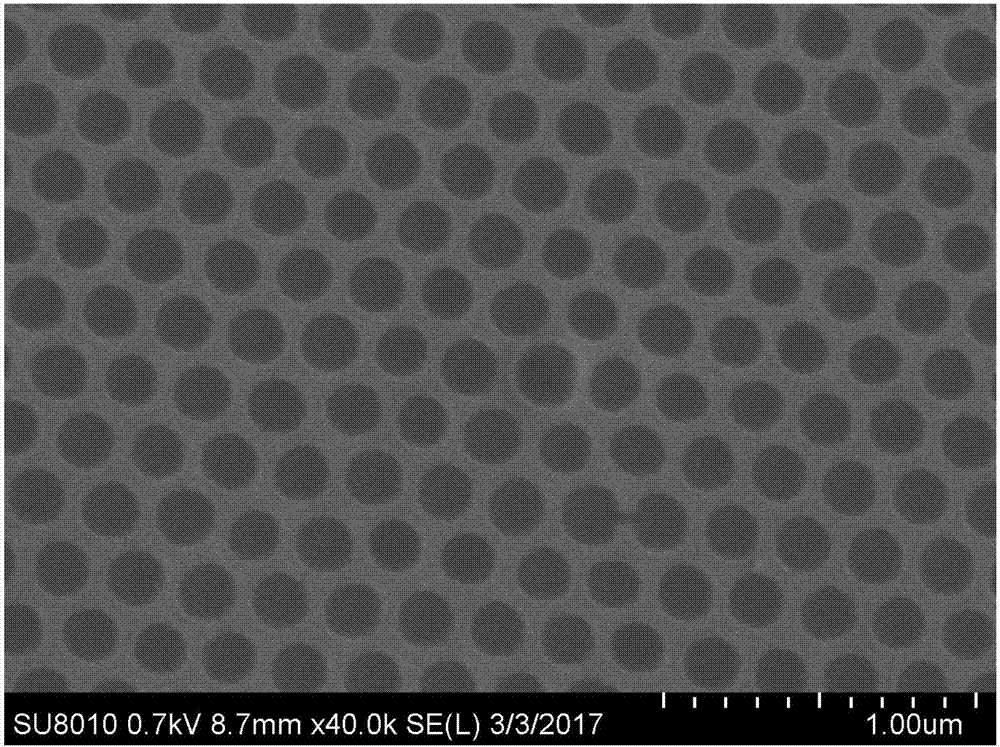

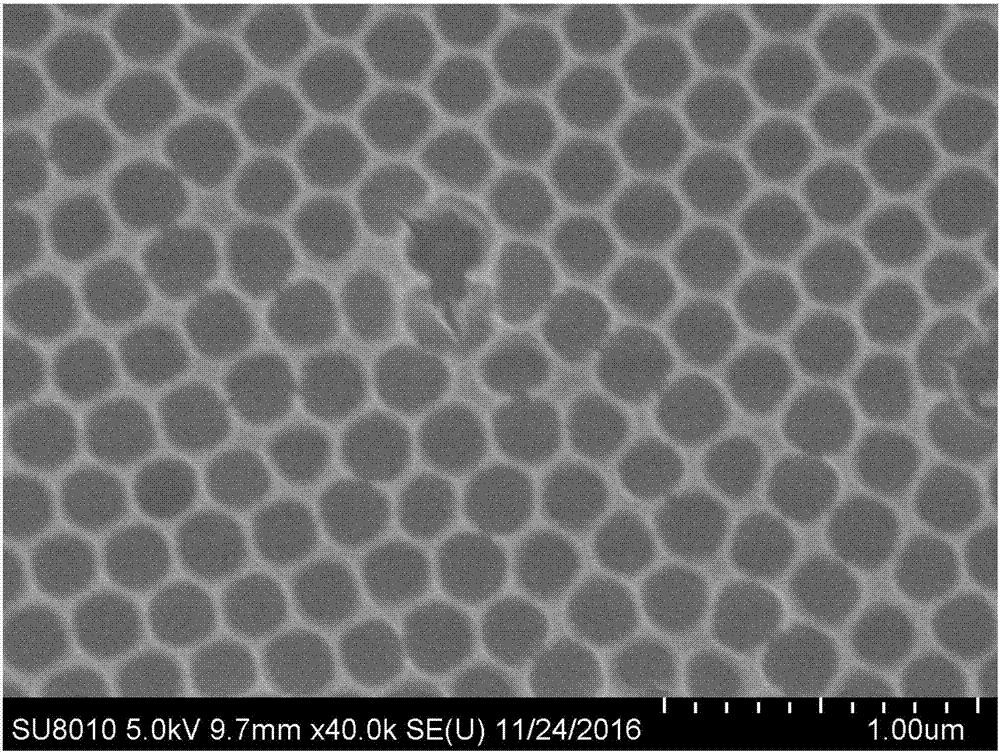

[0032] (2) Add polystyrene microspheres to the silicate sol to make it float on the surface of the silicate sol, and obtain a silicate film with a macroporous array compounded with a pore-forming agent through a self-assembly reaction, and age after film formation 20 to 60 minutes to obtain a silicate-microsphere composite film;

[0033] (3) Load the silicate-microsphere composite film on a glass slide, dry it at 50°C for 12 hours, and then calcinate it at 300°C-400°C. After the calcination, remove the microsphere template to obtain anti-glare porous Composite film.

[0034]...

Embodiment 2

[0036] This example discloses a method for preparing an anti-glare porous composite film, the preparation process of which is as follows:

[0037] (1) Add 6g of sodium silicate, 0.1g of sodium aluminate, 0.4g of sodium hydroxide, and 60ml of deionized water to the reaction bottle in turn, react at room temperature for 2 hours, seal up after the reaction, and age for 12 hours to obtain silicon Salt sol;

[0038] (2) Add polymethyl methacrylate microspheres to the silicate sol to float on the surface of the silicate sol, and obtain a macroporous array silicate film compounded with a pore-forming agent through a self-assembly reaction, forming a film Post-aging for 20-60 minutes to obtain a silicate-microsphere composite film;

[0039] (3) Load the silicate-microsphere composite film on a glass slide, dry it at 50°C for 12 hours, and then calcinate it at 300°C-400°C. After the calcination, remove the microsphere template to obtain anti-glare porous Composite film.

[0040] Suc...

Embodiment 3

[0042] This example discloses a method for preparing an anti-glare porous composite film, the preparation process of which is as follows:

[0043] (1) Add 0.8ml of concentrated ammonia water, 17.2ml of tetraethyl orthosilicate, and 55ml of deionized water in sequence in the reaction bottle, react at room temperature for 2 hours, seal up after the reaction, and age for 12 hours to obtain a silicate sol;

[0044] (2) Add polymethyl methacrylate microspheres to the silicate sol to float on the surface of the silicate sol, and obtain a macroporous array silicate film compounded with a pore-forming agent through a self-assembly reaction, forming a film Post-aging for 20-60 minutes to obtain a silicate-microsphere composite film;

[0045] (3) Load the silicate-microsphere composite film on a glass slide, dry it at 50°C for 12 hours, and then calcinate it at 300°C-400°C. After the calcination, remove the microsphere template to obtain anti-glare porous Composite film.

[0046]The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com