Degradable waterborne polyurethane/polyvinyl alcohol composite material and preparation method therefor

A technology of water-based polyurethane and polyvinyl alcohol, applied in the field of degradable water-based polyurethane/polyvinyl alcohol composite materials, the preparation of the above-mentioned degradable water-based polyurethane/polyvinyl alcohol composite materials, can solve the problem of incomplete degradation, excessive organic solvents, etc. problems, achieve the effects of low organic solvent content, improved degradation performance, and enhanced thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

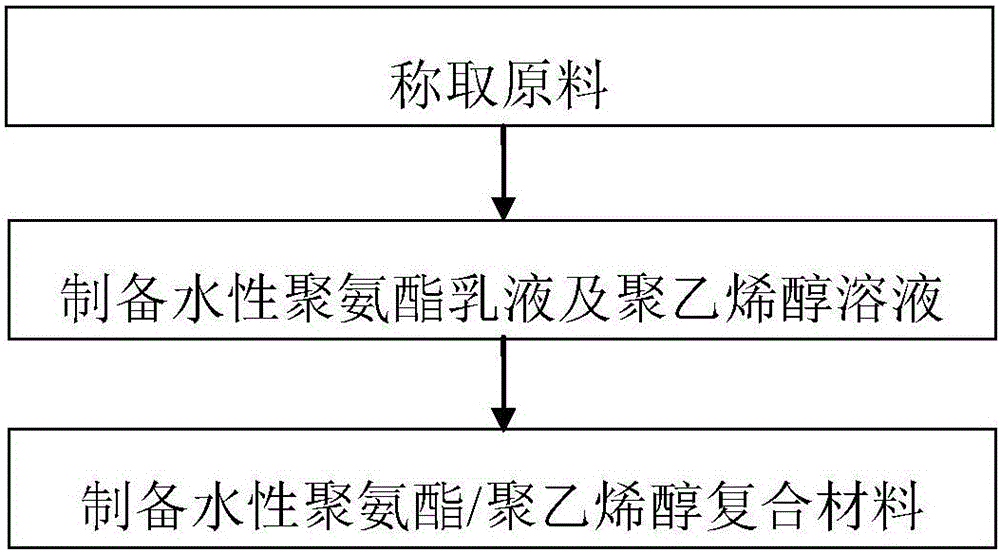

Method used

Image

Examples

preparation example Construction

[0050] The preparation of polyvinyl alcohol solution is carried out as follows:

[0051] The polyvinyl alcohol is dissolved in distilled water, soaked for 2-2.5 hours first, and then stirred in a 90°C constant temperature water bath for 2 hours to completely dissolve the polyvinyl alcohol to prepare a polyvinyl alcohol solution with a mass fraction of 12-18%.

[0052] As a preferred solution of the embodiment of the present invention, in step 3, when preparing the water-based polyurethane / polyvinyl alcohol composite material, the water-based polyurethane emulsion and polyvinyl alcohol solution obtained in step 2 are mixed and stirred evenly according to the volume ratio of 1:1, and the obtained mixed The solution is placed on a polytetrafluoroethylene plate, and after it is leveled, it is dried to remove moisture to obtain a degradable water-based polyurethane / polyvinyl alcohol composite material.

[0053] As a preferred version of the embodiment of the present invention, in s...

Embodiment 1

[0065] Embodiment 1, degradable waterborne polyurethane / polyvinyl alcohol composite material, adopts the raw material of mass parts in Table 1:

[0066] Table 1 Degradable waterborne polyurethane / polyvinyl alcohol composite raw material ratio (mass parts)

[0067]

[0068] Preparation:

[0069] First prepare the waterborne polyurethane prepolymer:

[0070] 1) Dry the hydroxyl-terminated L-lactic acid-3000 (PLLA-3000) and polyneopentyl adipate-2000 (PNA-2000) in vacuum at 120°C for 2 hours, and then put the hydroxyl-terminated L-lactic acid and poly Add neopentyl glycol adipate into a clean four-neck flask equipped with a reflux condenser, thermometer and stirring device, put the flask into a constant temperature water bath at 85°C and stir, melt and blend for 30 minutes; raw material PLLA-3000 Indicates that the molecular weight of PLLA is 3000, and PNA-2000 indicates that the molecular weight of PNA is 3000.

[0071] 2) Add isophorone diisocyanate, heat up to 90°C, and ...

Embodiment 2

[0077] Embodiment 2, degradable water-based polyurethane / polyvinyl alcohol composite material, adopts the raw material of mass parts in Table 2:

[0078] Table 2 Degradable waterborne polyurethane / polyvinyl alcohol composite raw material ratio (mass parts)

[0079]

[0080] Preparation:

[0081] First prepare the waterborne polyurethane prepolymer:

[0082] 1) The hydroxyl-terminated L-lactic acid-3000 (PLLA-3000) and polyneopentyl adipate-2000 (PNA-2000) were vacuum-dried at 120°C for 1.5 hours, and then the hydroxyl-terminated L-lactic acid and poly Add neopentyl glycol adipate into a clean four-necked flask with a reflux condenser, a thermometer and a stirring device, put the flask into a constant temperature water bath at 85°C and stir, and melt and blend for 45 minutes;

[0083] 2) Add isophorone diisocyanate, heat up to 90°C, and stir for 3 hours;

[0084] 3) Add dibutyltin dilaurate and continue to stir for 40 minutes;

[0085] 4) Lower the temperature of the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com