Treatment process for heavy metal sewage

A treatment process and heavy metal technology, applied in water/sewage treatment, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of low adsorption capacity, low heavy metal adsorption efficiency, poor sewage treatment effect, etc., to achieve Increased adsorption capacity, good biocompatibility, enhanced chelation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

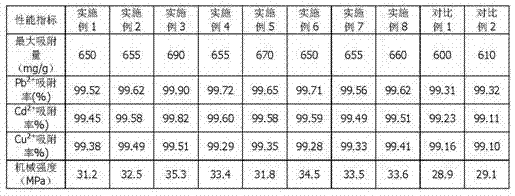

Examples

Embodiment 1

[0027] A treatment process for heavy metal sewage, comprising the steps of:

[0028] 1) Pretreatment of sedimentation and decolorization of sewage to be treated;

[0029] 2) Add the compound of magnetotactic bacteria and gel to the pretreated sewage, and mix it thoroughly to achieve the adsorption balance of heavy metals;

[0030] 3) Separating the complex of magnetotactic bacteria and gel with an external magnetic field to achieve the purpose of removing heavy metals and purifying sewage;

[0031] 4) Place the complex of the isolated magnetotactic bacteria and gel in an electric field for electrolytic reduction and replacement of simple metals, so as to realize the recycling of the complex of heavy metals, magnetotactic bacteria and gel.

[0032] The gel is composed of the following components in parts by weight: chitosan 40, epichlorohydrin 40, β -cyclodextrin 40, polyvinyl alcohol 30, sodium alginate 20, amino acid 10, sodium carboxymethylcellulose 0.3, graphene oxide 40,...

Embodiment 2

[0040] A treatment process for heavy metal sewage, comprising the steps of:

[0041] 1) Pretreatment of sedimentation and decolorization of sewage to be treated;

[0042] 2) Add the compound of magnetotactic bacteria and gel to the pretreated sewage, and mix it thoroughly to achieve the adsorption balance of heavy metals;

[0043] 3) Separating the complex of magnetotactic bacteria and gel with an external magnetic field to achieve the purpose of removing heavy metals and purifying sewage;

[0044] 4) Place the complex of the isolated magnetotactic bacteria and gel in an electric field for electrolytic reduction and replacement of simple metals, so as to realize the recycling of the complex of heavy metals, magnetotactic bacteria and gel.

[0045] The gel is composed of the following components in parts by weight: chitosan 100, epichlorohydrin 100, β -cyclodextrin 100, polyvinyl alcohol 60, sodium alginate 50, amino acid 30, sodium carboxymethylcellulose 0.3, graphene oxide ...

Embodiment 3

[0053] A treatment process for heavy metal sewage, comprising the steps of:

[0054] 1) Pretreatment of sedimentation and decolorization of sewage to be treated;

[0055] 2) Add the compound of magnetotactic bacteria and gel to the pretreated sewage, and mix it thoroughly to achieve the adsorption balance of heavy metals;

[0056] 3) Separating the complex of magnetotactic bacteria and gel with an external magnetic field to achieve the purpose of removing heavy metals and purifying sewage;

[0057] 4) Place the complex of the isolated magnetotactic bacteria and gel in an electric field for electrolytic reduction and replacement of simple metals, so as to realize the recycling of the complex of heavy metals, magnetotactic bacteria and gel.

[0058] The gel is composed of the following components in parts by weight: chitosan 70, epichlorohydrin 70, graphene oxide 70, β - Cyclodextrin 70, polyvinyl alcohol 45, sodium alginate 35, amino acid 20, sodium carboxymethylcellulose 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com