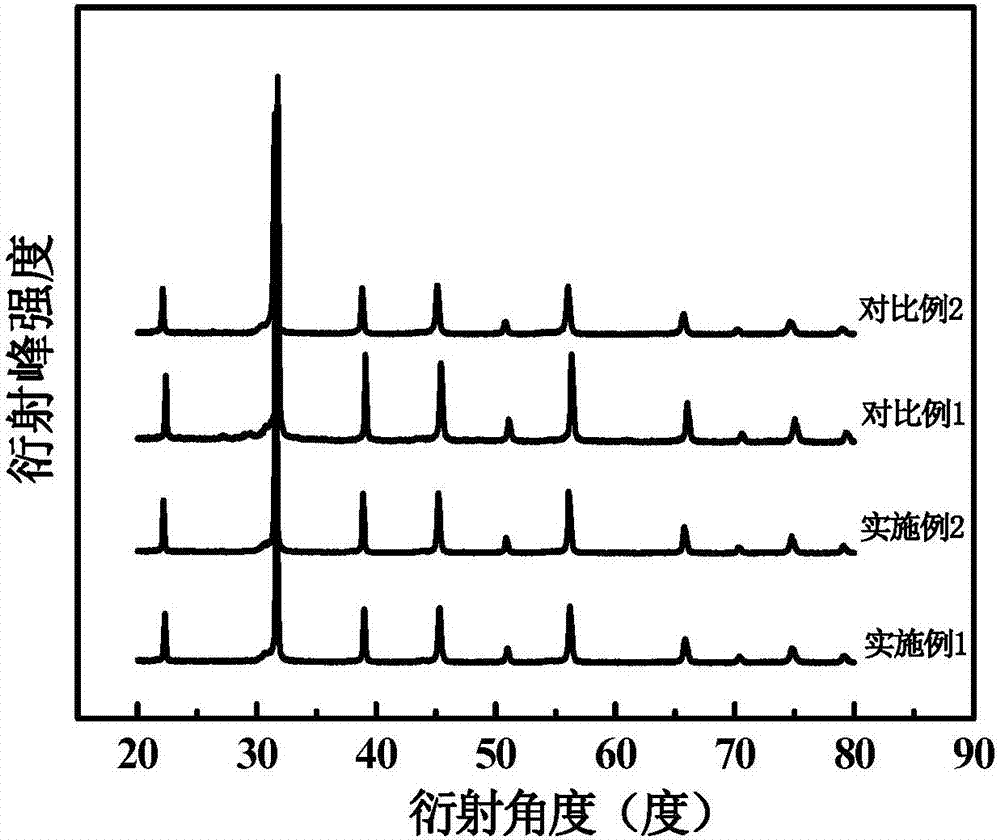

Coprecipitation preparation method for calcium barium zirconate titanate leadless piezoelectric ceramic material

A technology of barium calcium zirconate titanate and ceramic materials, which is applied in the field of ceramic materials, can solve problems such as harsh reaction conditions, lower reaction temperature, and difficult operation, and achieve the effects of low cost, high activity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

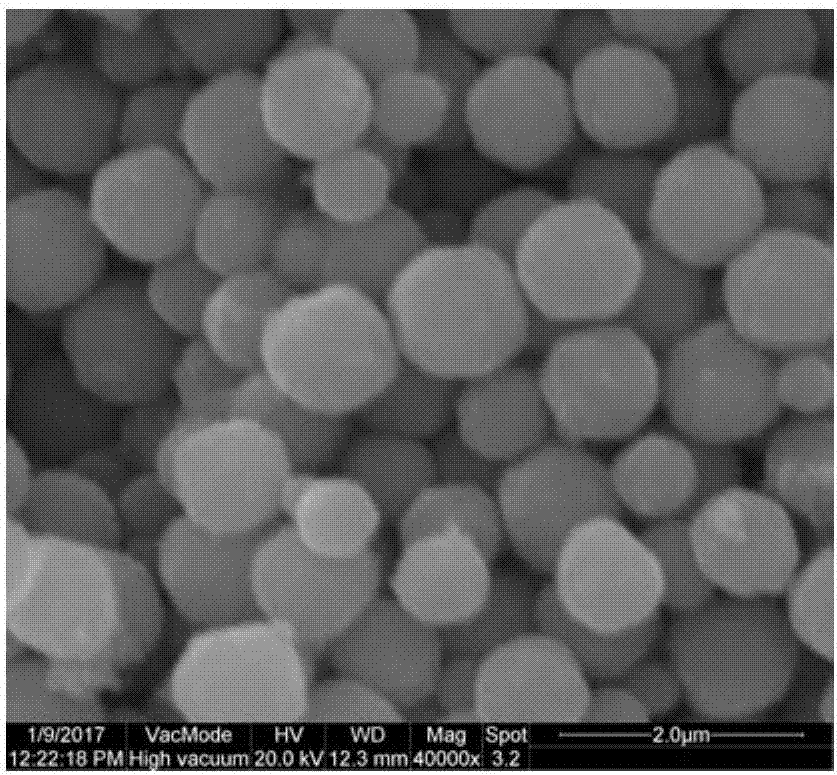

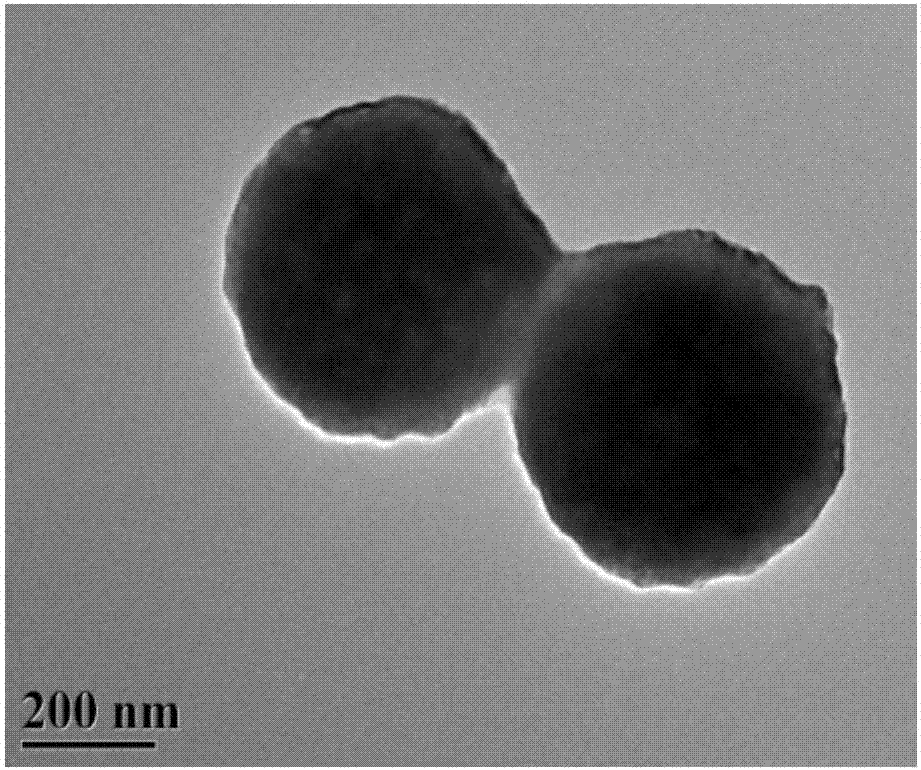

Embodiment 1

[0025] 1. 2.7941g (10.83mmol) Ba(CH) with a purity of 99% 3 COO) 2 , 0.3416g (1.9mmol) Ca(CH) with a purity of 98% 3 COO) 2 ·H 2 O was completely dissolved in 100 mL of distilled water to obtain A-site precursor solution; 0.4316 g (1 mmol) of Zr (NO 3 ) 4 ·5H 2 O, 1.7420g (9mmol) TiCl 4 Completely dissolve in 100mL of distilled water to obtain the B-position precursor solution; add the B-position precursor solution dropwise to 100mL of 8mol / L NaOH aqueous solution, stir well at room temperature, then add the A-position precursor solution dropwise, and stir at room temperature after the dropwise addition Evenly, the temperature was raised to 90 °C, and the reaction was stirred at a constant temperature for 4 hours. After the reaction was completed, it was aged at room temperature for 24 hours. Centrifugal washing with deionized water until the supernatant was neutral, suction filtration, and the filter cake was dried at 60 °C. Grind and pass through a 160-mesh sieve to o...

Embodiment 2

[0029] In step 1 of this example, 2.6471 g (10.2 mmol) of Ba(CH 3 COO) 2 , 0.3236g (1.8mmol) Ca(CH) with a purity of 98% 3 COO) 2 ·H 2 O was completely dissolved in 100 mL of distilled water to obtain A-site precursor solution; 0.4316 g (1 mmol) of Zr (NO 3 ) 4 ·5H 2 O, 1.7420g (9mmol) TiCl 4 It was completely dissolved in 100 mL of distilled water to obtain a precursor liquid at position B; other steps were the same as those in Example 1 to obtain a lead-free piezoelectric ceramic material of barium calcium zirconate titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com