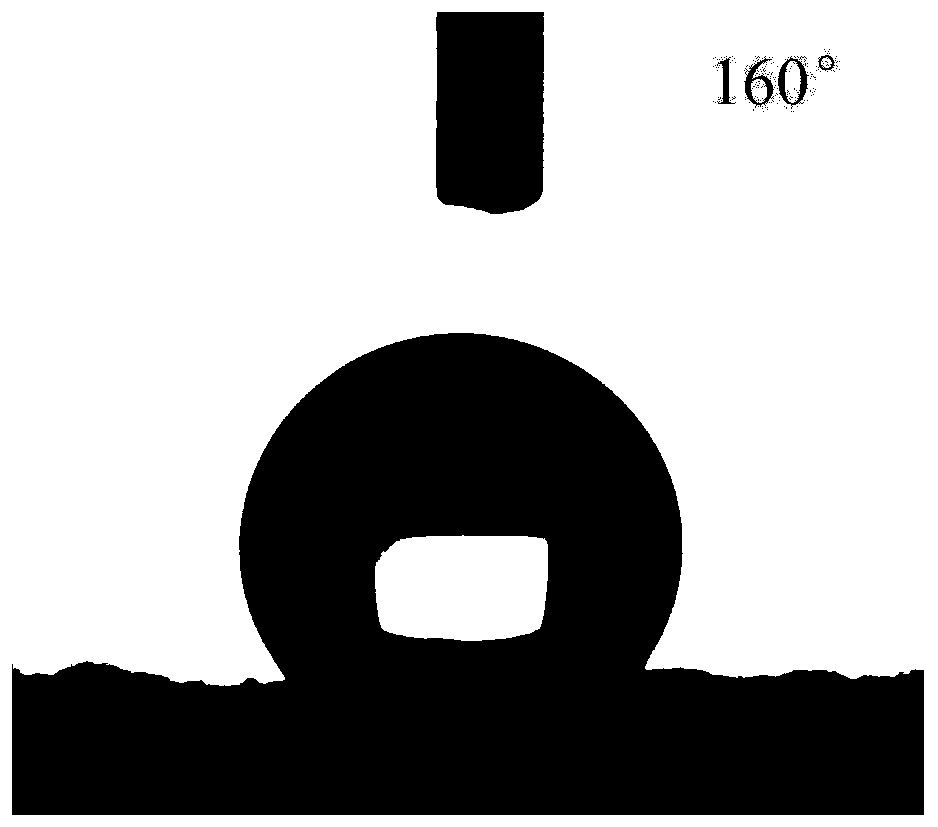

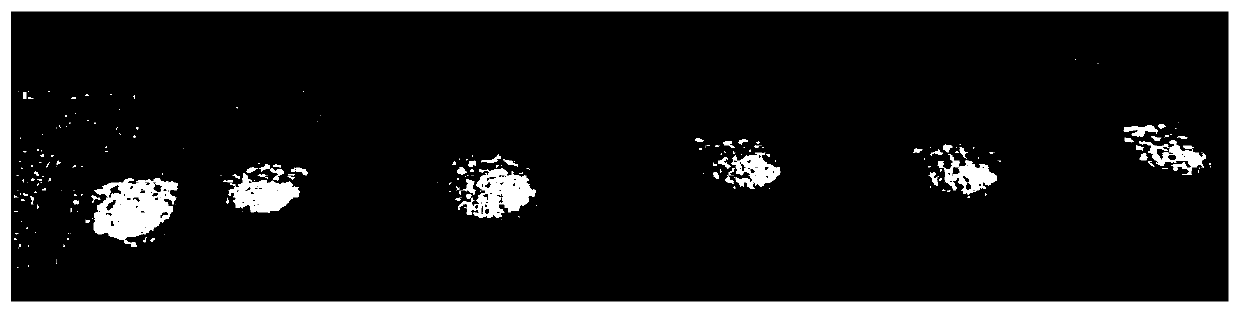

Multifunctional superhydrophobic textile finishing agent, its preparation method and application

A textile finishing and super-hydrophobic technology, which is applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of difficult process control, loss of super-hydrophobic properties, complicated and multi-step methods, etc., to achieve high-efficiency anti-ultraviolet and convenient The effect of large-scale production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] An aspect of the embodiments of the present invention provides a method for preparing a multifunctional superhydrophobic textile finishing agent, which includes:

[0026] (1) Disperse the precursor of the oxide sol and the graphite oxide aqueous dispersion in deionized water, add an anionic surfactant, and stir at room temperature for 20 to 30 minutes. After uniform dispersion, add a catalyst for hydrolysis and condensation reactions to form a mixed reaction system;

[0027] (2) Heating the mixed reaction system obtained in step (1) to 30-50° C., stirring and reacting at a speed of 200-1000 rpm for 3-12 hours, and then ultrasonically treating for 10-20 minutes to form a hydrosol;

[0028] (3) Add a functional agent to the hydrosol obtained in step (2), and perform ultrasonic treatment for 10-100 min to obtain the multifunctional superhydrophobic textile finishing agent.

[0029] In some embodiments, the precursor includes any one or a combination of two or more of tetr...

Embodiment 1

[0052] (1) Disperse 10 mL of tetrabutyl titanate and 4 mL of graphite oxide aqueous dispersion (concentration: 10 mg / mL) in 200 mL of deionized water, add 0.1 g of sodium dodecylbenzenesulfonate, and stir vigorously at room temperature for 20 min, After uniform dispersion, 5 mL of hydrochloric acid with a concentration of 0.1 mol / L was added dropwise to carry out hydrolysis and condensation reactions.

[0053] (2) The temperature of the mixed reaction system obtained in step (1) was raised to 30° C., and the magnetic stirring reaction was continued at a speed of 300 rpm for 3 h, followed by ultrasonic treatment for 10 min to obtain a clear and transparent hydrosol.

[0054] (3) Add 5mL of octyltriethoxysilane, 1gTiO 2 and carbon black, 0.2g polyphosphoric acid, 0.2g nano-silver and 0.4g silk protein, and then ultrasonically treated for 50 minutes to obtain a uniform and stable dispersion, which is the multifunctional superhydrophobic textile finishing agent.

[0055] (4) Take...

Embodiment 2

[0060] (1) Disperse 10mL tetraoctyl titanate and 2mL graphite oxide aqueous dispersion (concentration: 5mg / mL) in 100mL deionized water, add 0.05g sodium dodecylsulfonate, stir vigorously at room temperature for 30min, and After dispersion, 3 mL of ammonia water with a concentration of 0.05 mol / L was added dropwise to carry out hydrolysis and condensation reactions.

[0061] (2) The temperature of the mixed reaction system obtained in step (1) was raised to 35° C., and the magnetic stirring reaction was continued at a speed of 500 rpm for 5 h, followed by ultrasonic treatment for 15 min to obtain a clear and transparent hydrosol.

[0062] (3) Add 3mL dodecyltriethoxysilane, 2g ZnO and kaolin, 0.1g melamine, 0.1g nano-titanium oxide and 0.2g collagen to the hydrosol obtained in step (2), and then ultrasonically After 20 minutes, a uniform and stable dispersion is obtained, which is the multifunctional superhydrophobic textile finishing agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com