Preparation method for health product resveratrol

A technology for resveratrol and health care products, applied in the field of health care products, can solve the problems of being inconsistent with environmental protection, prone to side reactions, difficult to control the reaction, etc., and achieves good cycle repeatability, simple post-processing and purification, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

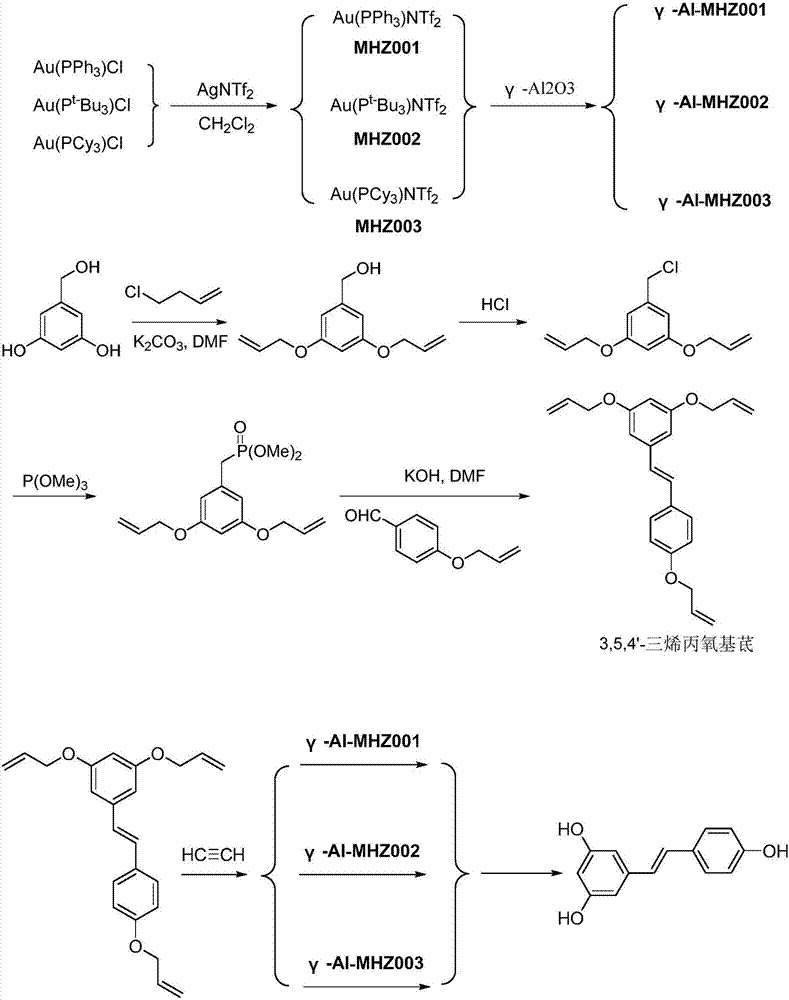

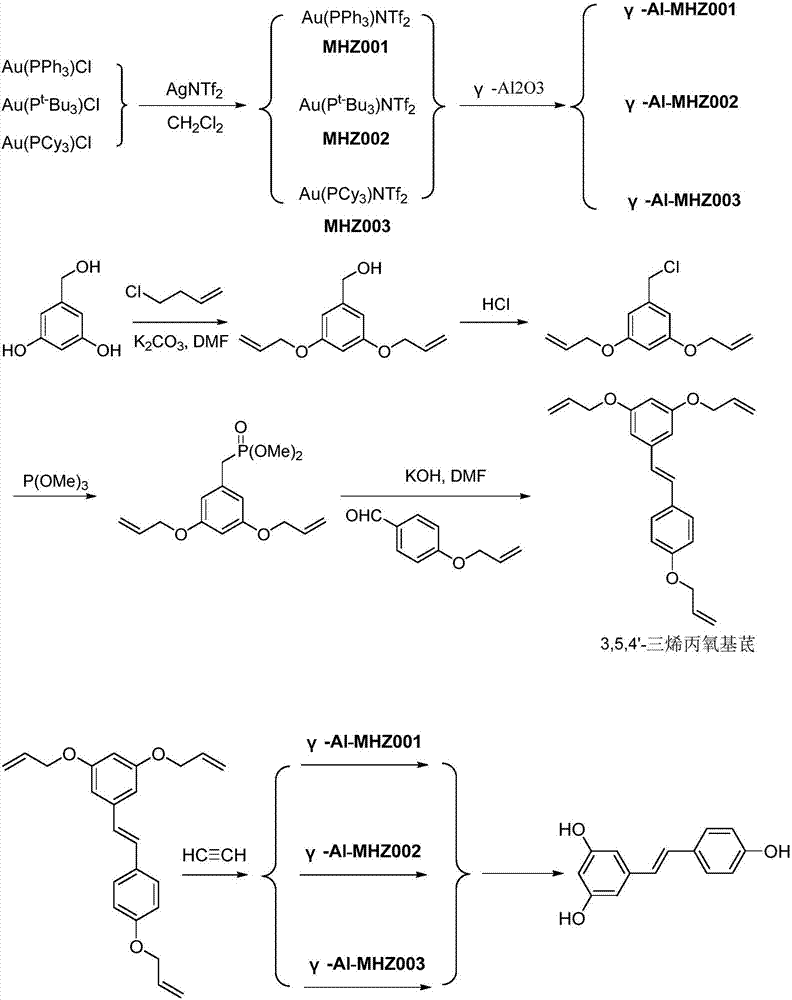

Method used

Image

Examples

Embodiment 1

[0024] Get 4.94g triphenylphosphine gold chloride and 3.87g and two (trifluoromethanesulfonate group) silver ammonium in the reaction flask of 50ml band magnetic stirrer, after replacing reaction flask with argon gas 5 times, add 8.4g di Chloromethane, stirred at room temperature for 1 h. After completion of the reaction, suction filter the mother liquor into a new 100ml reaction flask, wash the filter cake with 8.4g of dichloromethane, and dry the by-product silver chloride; combine the filtrates to obtain a dichloromethane solution of MHZ001. Add 20g of γ-alumina to the dichloromethane solution of the obtained MHZ001, adjust the data of the rotary evaporator to 40°C, 0.01MPa, and evaporate the impregnation solution to dryness to obtain the γ-Al-MHZ001 catalyst, which can be used by recovering the dichloromethane.

[0025] Take 34.8g of the prepared 3,5,4'-triallyloxystilbene and place it in a 250ml reaction flask with a magnetic stirrer, add 84g of dichloromethane and stir t...

Embodiment 2

[0027] Get 4.94g triphenylphosphine gold chloride and 3.87g and two (trifluoromethanesulfonic acid group) silver ammonium in the reaction flask of 100ml band magnetic stirrer, after replacing reaction flask with argon gas 5 times, add 42g dichloro methane, stirred at room temperature for 1 h. After completion of the reaction, suction filter the mother liquor into a new 100ml reaction flask, wash the filter cake with 8.4g of dichloromethane, and dry the by-product silver chloride; combine the filtrates to obtain a dichloromethane solution of MHZ001. Add 20g of γ-alumina to the dichloromethane solution of the obtained MHZ001, adjust the data of the rotary evaporator to 40°C, 0.01MPa, and evaporate the impregnation solution to dryness to obtain the γ-Al-MHZ001 catalyst, which can be used by recovering the dichloromethane.

[0028] Take 34.8g of the prepared 3,5,4'-triallyloxystilbene and place it in a 250ml reaction flask with a magnetic stirrer, add 168g of dichloromethane and s...

Embodiment 3

[0030] Get 4.34g tri-tert-butylphosphine gold chloride and 3.87g and two (trifluoromethanesulfonic acid group) silver ammonium in the reaction bottle of 50ml band magnetic stirrer, after replacing reaction bottle with argon gas 5 times, add 8.4g Dichloromethane was stirred at room temperature for 1 h. After the reaction is complete, suction filter the mother liquor into a new 100ml reaction flask, wash the filter cake with 8.4g of dichloromethane, and dry the by-product silver chloride; combine the filtrates to obtain a dichloromethane solution of MHZ002. Add 20g of γ-alumina to the dichloromethane solution of the obtained MHZ001, adjust the data of the rotary evaporator to 40°C, 0.01MPa, and evaporate the impregnation solution to dryness to obtain the γ-Al-MHZ002 catalyst, which can be used by recovering the dichloromethane.

[0031] Take 34.8g of the prepared 3,5,4'-triallyloxystilbene and place it in a 250ml reaction flask with a magnetic stirrer, add 84g of dichloromethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com