Texturizing method for monocrystalline silicon wafer and texturizing additive used in texturizing method

A technology of silicon silicon wafers and additives, which is applied in the field of monocrystalline silicon wafer texturing methods and its texturing additives, can solve the problems of slow alkali etching silicon wafers, reduce production costs, and low production efficiency, and achieve silicon etching The effect of increasing sheet speed, reducing production cost, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The monocrystalline silicon wafer texturing method of the present invention is prepared according to the following steps:

[0032] 1) Put the damage layer of P-type mortar wire-cut single crystal silicon wafer with a size of 156mm×156mm and a thickness of 200±20μm into a HF solution with a mass fraction of 3% to remove SiO 2 layer, the cleaning time is 60 seconds, and the cleaning temperature is 20 °C; then use deionized water to clean for 3 times; dry the silicon wafer for use;

[0033] 2) Put the above-treated silicon wafer into a temperature of 0.0005mol / LAgNO 3 , 0.2mol / L H2O2, 2 mol / L HF solution for 120s corrosion, the reaction temperature is 20℃;

[0034] 3) Wash the silicon wafer after the above treatment in deionized water for 60s, and the cleaning temperature is 20℃;

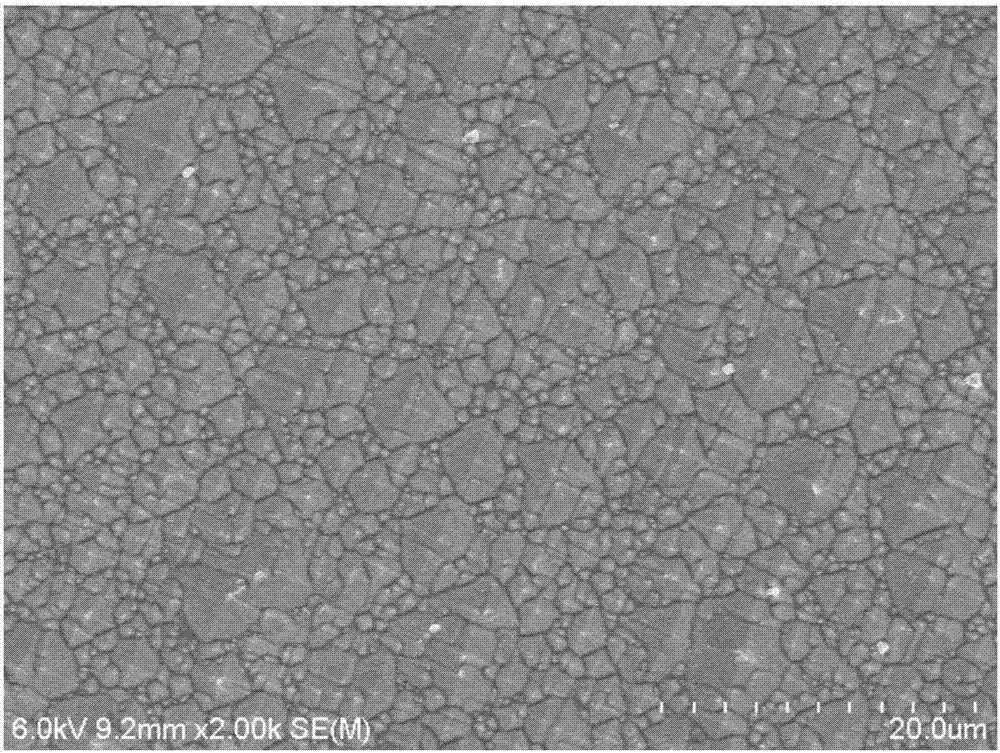

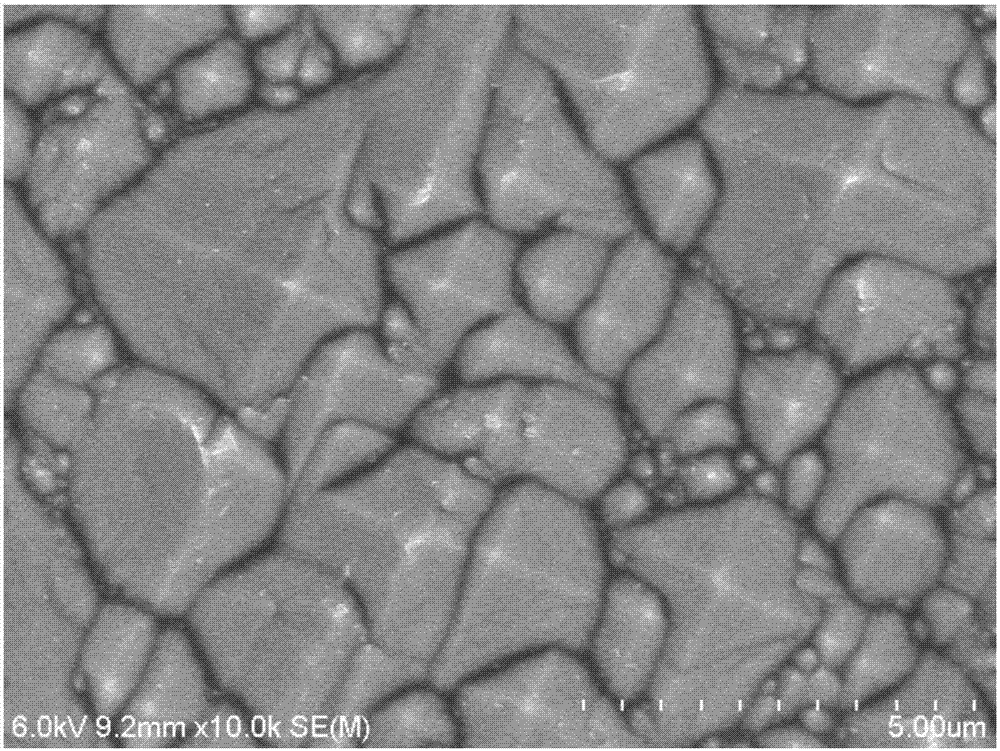

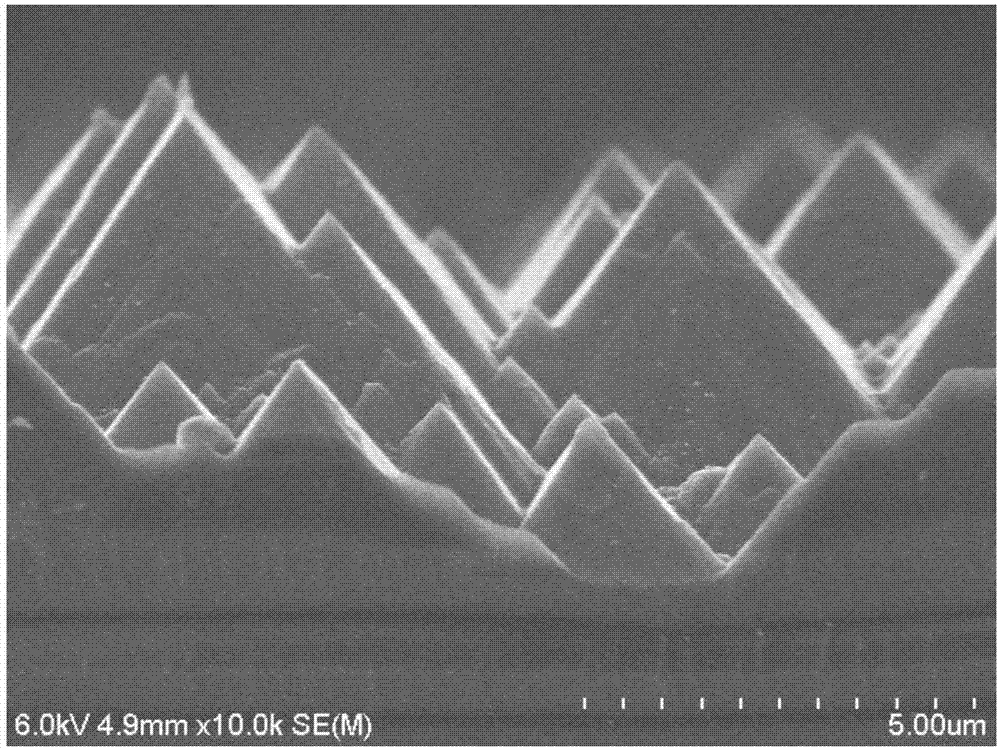

[0035] 4) The above silicon wafer was reacted in 2%wt NaOH, 0.001%wt surfactant, and 0.02%wt soluble starch for 300s, and the reaction temperature was 60°C;

[0036] 5) Washing the above sili...

Embodiment 2

[0039] 1) Put the damaged layer of P-type diamond wire-cut single crystal silicon wafer with a size of 156mm×156mm and a thickness of 180±10μm into a HF solution with a mass fraction of 3% to remove SiO 2 layer, the cleaning time is 60 seconds, and the cleaning temperature is 20 °C; then use deionized water to clean for 3 times; dry the silicon wafer for use;

[0040] 2) Put the above-treated silicon wafer into a temperature of 0.0001mol / LAgNO 3 , 0.5mol / L H 2 O 2 , 5 mol / L HF solution for 180s corrosion, the reaction temperature is 20℃;

[0041] 3) Wash the silicon wafer after the above treatment in deionized water for 60s, and the cleaning temperature is 20℃;

[0042] 4) The above silicon wafer was reacted in a solution containing 2%wtKOH, 0.001%wt glucose, and 0.02%wt sodium acetate for 360s, and the reaction temperature was 60°C;

[0043] 5) Washing the above silicon wafer in deionized water and drying, the pyramid suede surface with excellent light trapping performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com