MoS2-xOx/carbon negative electrode material and preparation method thereof

A carbon negative electrode material, mos2-xox technology, applied in battery electrodes, electrical components, electrochemical generators, etc., to achieve the effects of improving energy and cycle performance, increasing specific capacity, and improving volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

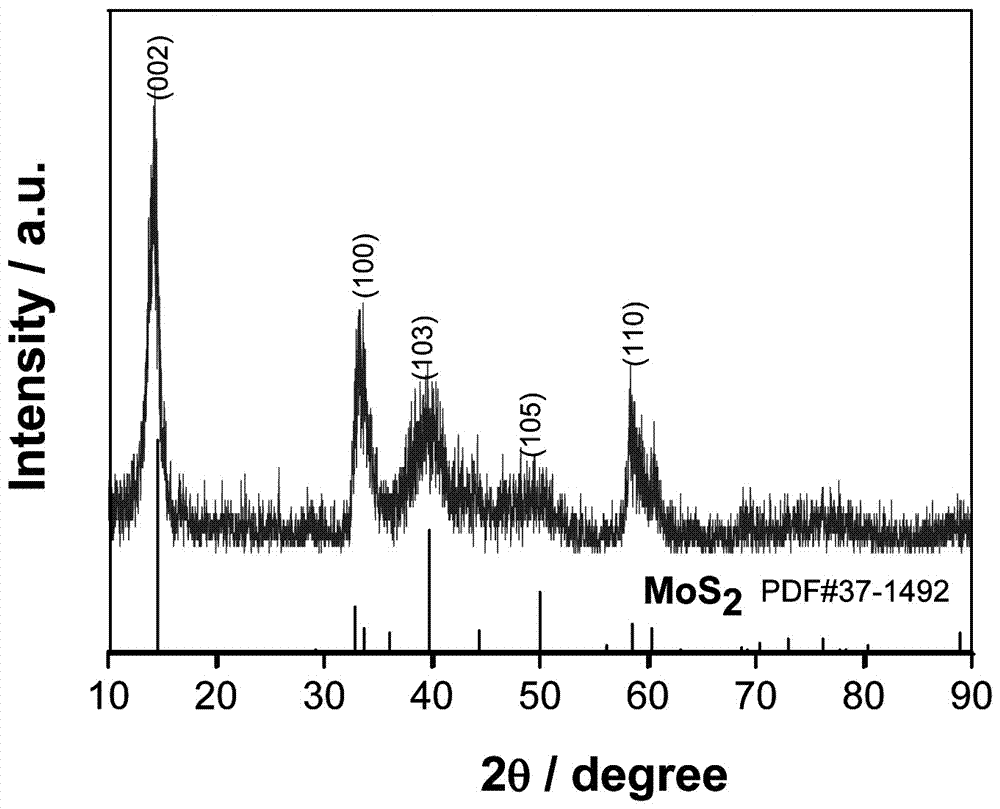

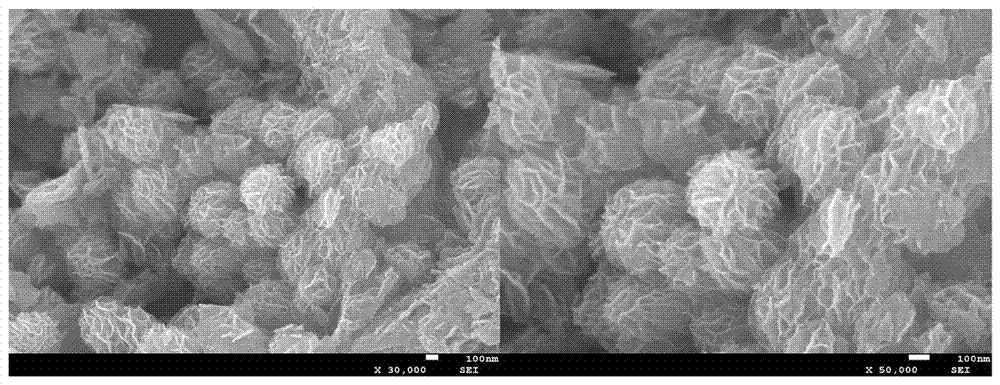

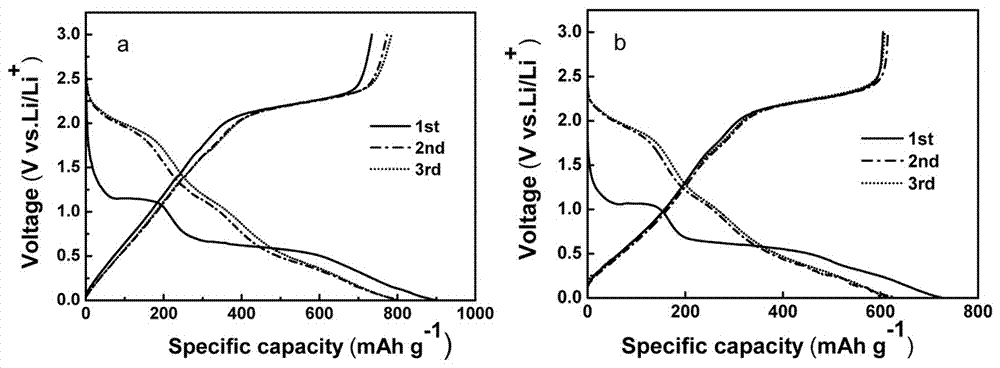

[0018] Embodiment 1: A kind of MoS 1.9 o 0.1 / Carbon negative electrode material and preparation method thereof

[0019] Wet paper towel in 1 mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then placed in a drying oven at 60° C. for 12 hours to obtain a treated wet tissue. Take concentration 12 mg mL -1 10mL of graphene oxide was evenly coated on the surface of 0.1g wet paper towel, dried, and then placed in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea for 24 hours at 200°C. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 , graphene oxide reduction. The material was calcined in a tube furnace at 800° C. for 4 hours, and the crystallinity and carbonization degree of the material ...

Embodiment 2

[0020] Example 2 is a kind of MoS 1.8 o 0.2 / Carbon negative electrode material and its preparation method Ⅱ

[0021] Wet paper towel in 1 mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then placed in a drying oven at 60° C. for 12 hours to obtain a treated wet tissue. Take concentration 12 mg mL -1 10 mL of graphene oxide was uniformly coated on the surface of 0.1g wet paper towel, dried, and then put it in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea for 24 hours at 200°C. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 , graphene oxide reduction. The material was calcined in a tube furnace at 800°C for 4h. While calcining, the crystallinity and carbonization degree of the m...

Embodiment 3

[0022] Example 3 A kind of MoS 1.7 o 0.3 / Carbon negative electrode material and its preparation method Ⅲ

[0023] Wet paper towel in 1 mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then placed in a drying oven at 60° C. for 12 hours to obtain a treated wet tissue. Take concentration 12 mg ml -1 10ml of graphene oxide was uniformly coated on the surface of 0.1g wet paper towel, dried, and then placed in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea for 24 hours at 200°C. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 , graphene oxide reduction. The material was calcined in a tube furnace at 800°C for 4h. While calcining, the crystallinity and carbonization degree of the material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com