Hollow MnO2 composite nanomaterial, preparation method and application thereof

A composite nanomaterial and hollow technology, which is applied in the field of biomedicine, can solve the problems of complex synthesis steps, uncontrollable morphology of MnO2 materials, and difficulty in mass synthesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

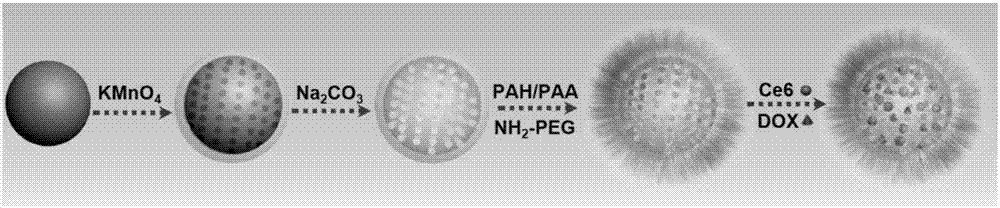

[0035] The invention provides a hollow MnO 2A method for preparing a composite nanomaterial, comprising the steps of:

[0036] a) dissolving ethyl orthosilicate in a mixed solution of ethanol and alkaline aqueous solution, and hydrolyzing to obtain solid silica nanoparticles;

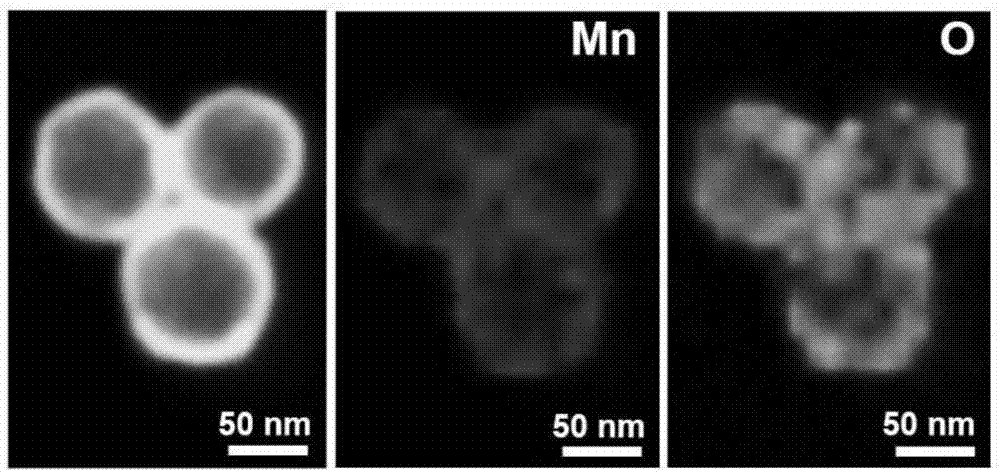

[0037] b) Mix the aqueous solution of the solid silica nanoparticles with the potassium permanganate solution, perform a reduction reaction and then etch to obtain a hollow MnO 2 nanoparticles;

[0038] c) the hollow MnO 2 The surface of nanoparticles was sequentially modified with polyacrylamine hydrochloride layer, polyacrylic acid layer and aminated polyethylene glycol layer to obtain hollow MnO 2 composite nanomaterials.

[0039] The preparation method provided by the present invention is simple, using solid silica spheres as a template, a large amount of materials with controllable hollow structures can be obtained in one experiment, and has simple synthesis steps, good repeatability and high y...

Embodiment 1

[0065] Embodiment 1: prepare hollow MnO 2 Material (H-MnO 2 -PEG):

[0066] (1) Mix and stir 14 mL of ethanol, 2 mL of water and 500 μL of ammonia water (30%), slowly add 100 μL of tetraethyl orthosilicate dropwise in a water bath at 45°C for 2 hours, and then wash with water three times to obtain solid silica nanoparticles (sSiO 2 ).

[0067] (2) 40mg of sSiO 2 Dispersed in 10 mL of water, an aqueous solution of potassium permanganate (300 mg) was added dropwise to the solution under ultrasonic conditions, after stirring for 12 h, the precipitate was obtained by centrifugation at 14800 rpm, washed three times with water and redispersed in water.

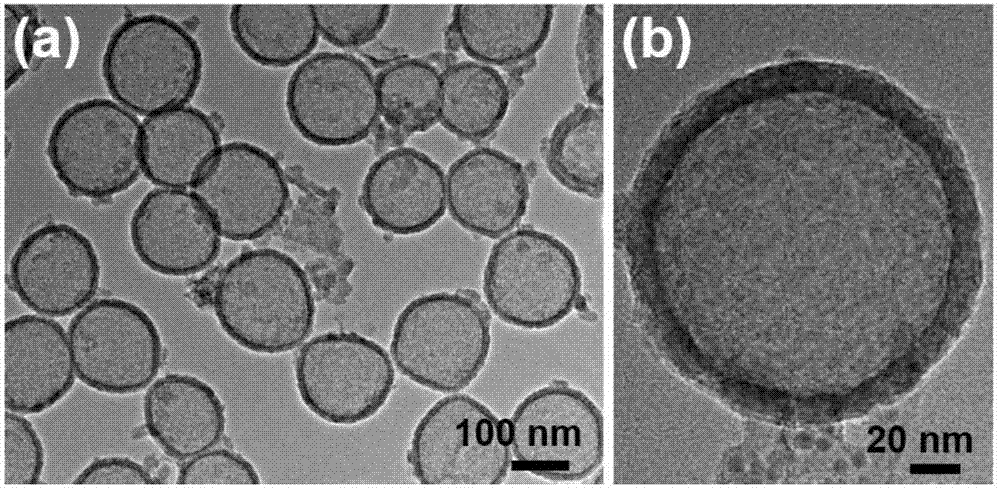

[0068] (3) Dissolve the material obtained in (2) in 2mol / L Na 2 CO 3 In aqueous solution, react at 60°C for 12h to obtain hollow mesoporous silica particles (H-MnO 2 ) and washed three times with water.

[0069] (4) Disperse 10 mL of polyallylamine hydrochloride (PAH, MW=15000) polymer solution (5 mg / mL) in a serum bottle, and...

Embodiment 2

[0077] Example 2: H-MnO 2 - Large-scale synthesis experiment of PEG nanoparticles

[0078] In order to further study the synthesis yield and repeatability of the material, the following experiments were designed:

[0079] According to the synthesis step (1) in the embodiment case 1, obtain 2g sSiO 2 And it was dispersed in 300 mL of water, and an aqueous solution of potassium permanganate (15 g) was added dropwise to the water under ultrasonic conditions. After stirring for 12 h, the precipitate was obtained by centrifugation at 14800 rpm, washed with water three times and dissolved in 2mol / L Na 2 CO 3 In aqueous solution, react at 60°C for 12h to obtain hollow mesoporous MnO 2 Particles (H-MnO 2 ) and washed three times with water.

[0080] Figure 6 It is the H-MnO synthesized on a large scale in Example 2 of the present invention 2 -TEM image of PEG material; in Figure 6 According to the experimental results, it can be found that 6g of material can be obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com