Mixed component material and preparation method thereof

A technology of mixing components and outer layer materials, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as short board in high temperature aging resistance, and achieve good synergy, excellent performance and good function. The effect of material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

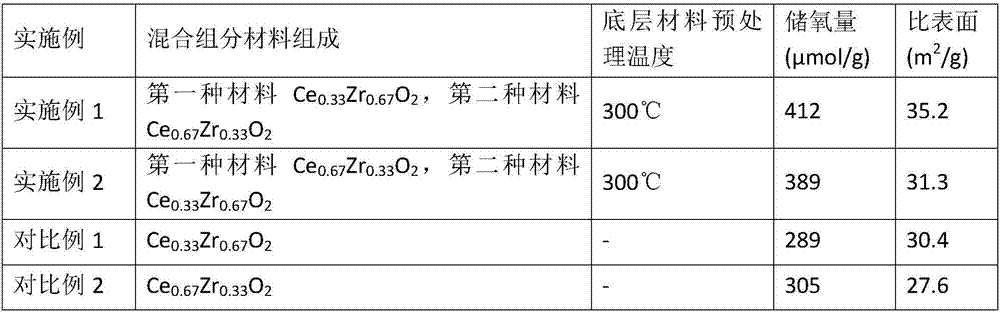

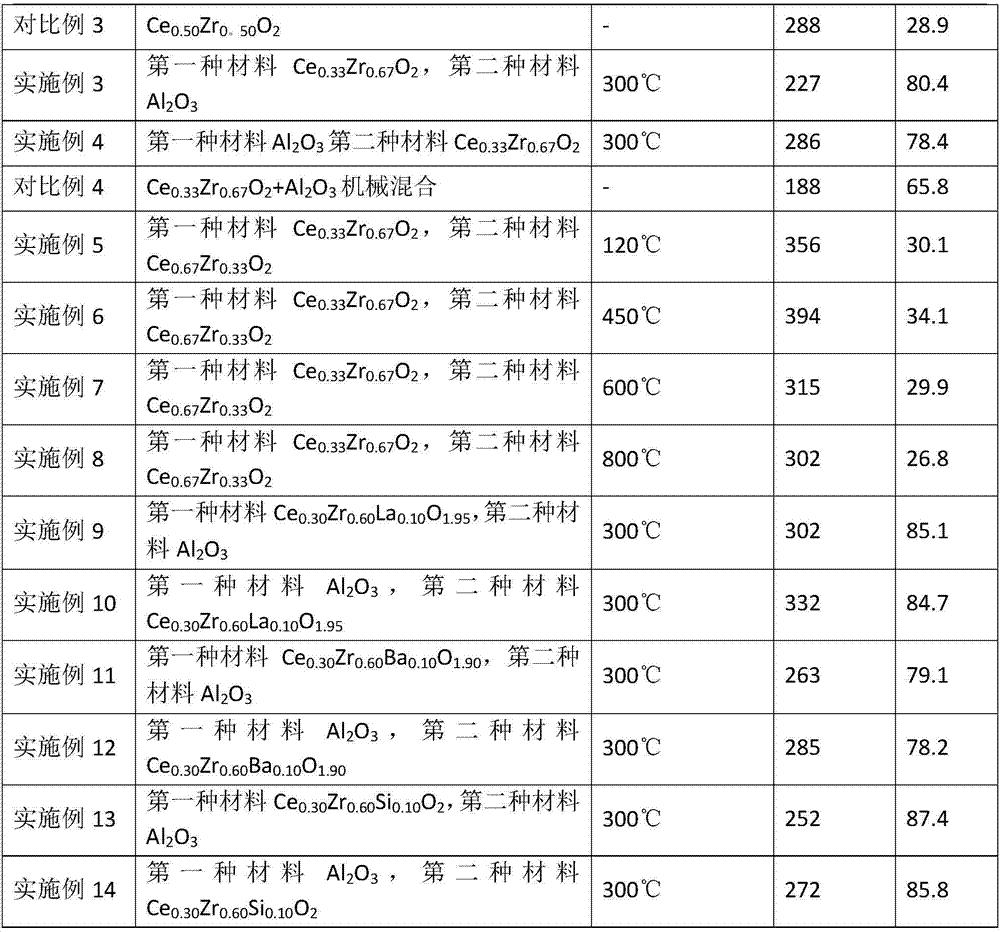

Examples

preparation example Construction

[0046] In a specific implementation case of the preparation scheme of the present invention, the method for preparing a mixed component material is used to prepare a composite material containing two or more components, including the following preparation steps:

[0047] In the first step, the saline solution of the bottom material, citric acid and deionized water are mixed, and the stirring is continued for 1-60 minutes. Ammonia solution (25 wt%) was added thereto to make pH = 4-10. Continue to stir for 0.5-10h and leave for 1-5 days. Suction filtration, washing with deionized water 1-4 times. Dry at 60-150°C for 1-12h, and treat at 200-600°C for 1-300min to obtain the pretreated material.

[0048] In the second step, the obtained pretreated material is placed in a container and stirred. Separately take the salt solution of the outer layer material, add it into the pretreatment material under stirring, and continue stirring for 1-60min. Ammonia solution (25 wt%) was added...

Embodiment 1

[0056] Prepare the bottom layer as Ce 0.33 Zr 0.67 o 2 , the outer layer is Ce 0.67 Zr 0.33 o 2 mixed component materials.

[0057] Get 69.0g zirconium carbonate and prepare zirconium nitrate solution with concentrated nitric acid (nitric acid content is 65wt%) dissolving, add cerium nitrate 51.5g in this solution under stirring, hydrogen peroxide (30% concentration) 15.4g, citric acid 10.0g and deionized water 450.0 g, and continued stirring for 10 min to obtain solution S1, in which Ce / Zr=1 / 2 (molar ratio). 150.0 g of ammonia solution (25 wt %) was added to S1 to make pH=9. Stirring was continued for 1h and left for 2 days. Suction filtration, washing with deionized water 3 times. Dry at 90°C for 5 hours, and pretreat at 300°C for 3 hours to obtain material S11. Material S11 is powder material. The resulting S11 was placed in a container and stirred.

[0058] In addition 30.4g zirconium carbonate is prepared zirconium nitrate solution with concentrated nitric acid...

Embodiment 2

[0062] Prepare the bottom layer as Ce 0.67 Zr 0.33 o 2 , the outer layer is Ce 0.33 Zr 0.67 o 2mixed component materials. Get 30.4g zirconium carbonate and prepare zirconium nitrate solution with concentrated nitric acid (nitric acid content is 65wt%) dissolving, add cerium nitrate 93.3g in this solution under stirring, hydrogen peroxide (30% concentration) 28g, citric acid 10.0g and deionized water 450.0g g, continue to stir for 10 min to prepare a solution S2, in which Ce / Zr=2 / 1 (molar ratio). 150.0 g of ammonia solution (25 wt %) was added to S2 to make pH=9. Stirring was continued for 1h and left for 2 days. Suction filtration, washing with deionized water 3 times. Dry at 90°C for 5 hours, and pretreat at 300°C for 3 hours to obtain material S21. The obtained S21 was placed in a container and stirred for 10 min. Another 69.0g zirconium carbonate is prepared zirconium nitrate solution with concentrated nitric acid (the nitric acid content is 65wt%) dissolving, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com