Ternary blending organic polymer solar cell device

A technology for solar cells and polymers, applied in the fields of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of open-circuit voltage and absorption spectrum limitations, complex production process of tandem cells, etc., achieve optimal photoelectric conversion efficiency, improve photoelectricity Conversion efficiency, the effect of broadening the spectral absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

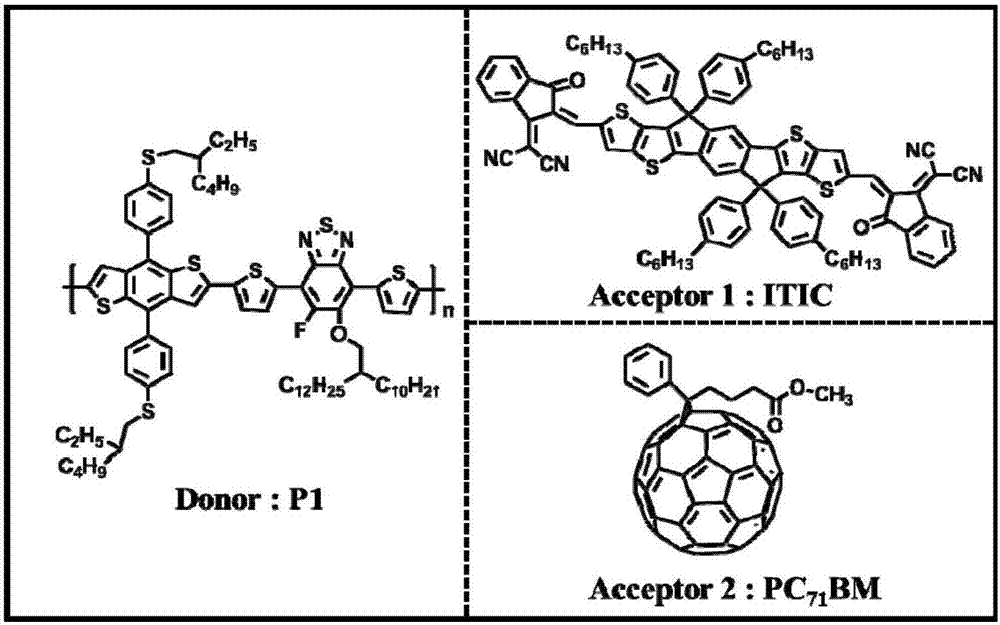

[0020] Embodiment 1: with figure 1 The three materials shown in are used as active layer materials for ternary blend organic polymer solar cell devices. Among them, the bandgap (Eg) of the wide bandgap polymer donor material P3 is 1.8eV; the molecular weight of the non-fullerene small molecule acceptor material ITIC is 1430, and the bandgap (Eg) is 1.7eV.

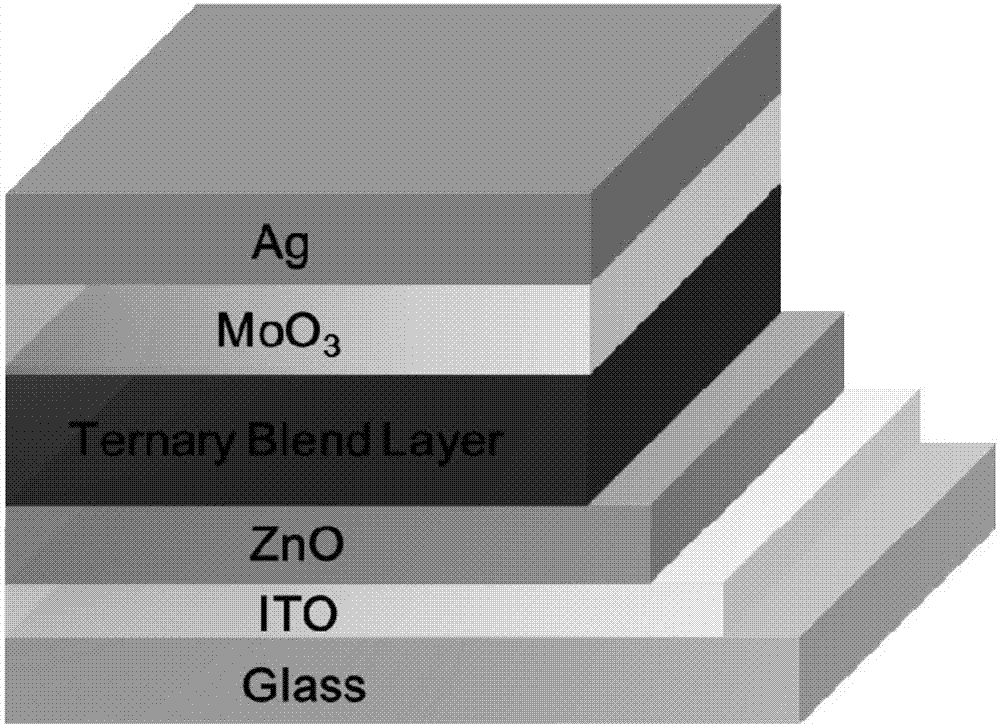

[0021] ITO / ZnO(30nm) / P3: ITIC: PC 71 BM(120nm) / MoO 3 (8.5nm) / Ag(100nm) device structure such as figure 2 shown. The content (mass percentage) of the non-fullerene small molecule acceptor material ITIC in the active layer of the device is 10%-60%. The fabrication process of the device is as follows:

[0022] 1. The ITO (transparent electrode) glass substrate is first cleaned with a detergent, and then rinsed with tap water, deionized water, and ethanol in order to remove surface grease and dust. Afterwards, deionized water, acetone, and isopropanol were used to sonicate for 15 minutes each, and placed in a vacuum dryi...

Embodiment 2

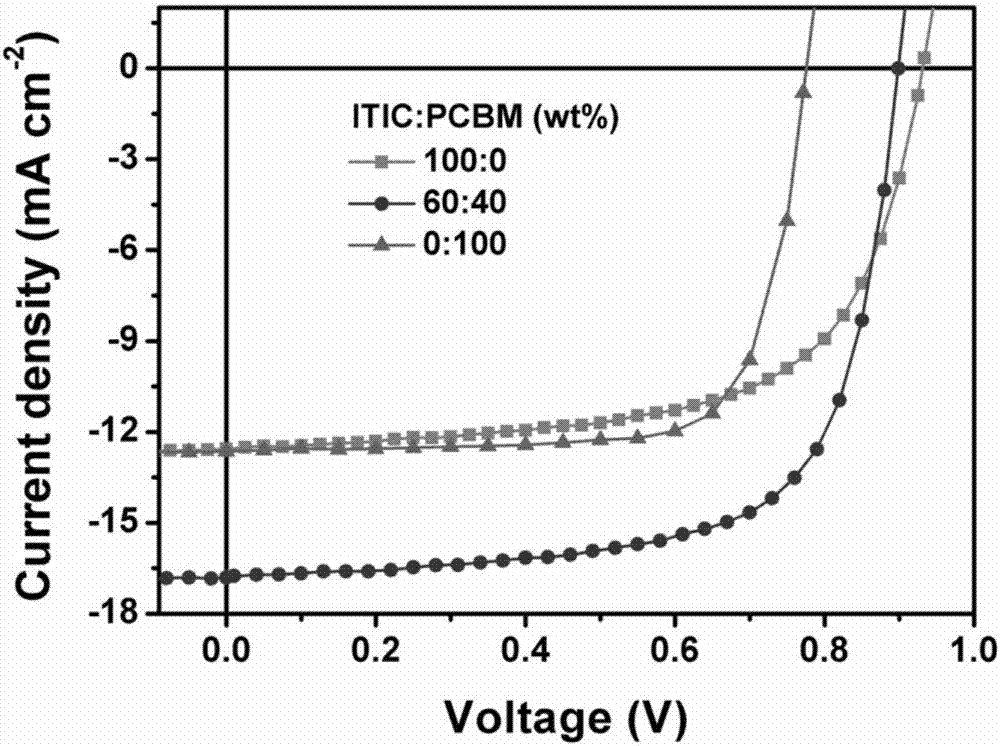

[0027] Example 2: A reference device was prepared according to the method of Example 1, except that the active layer of the device was a binary blend system, respectively P3:PCBM and P3:ITIC. The optimal performance of the obtained organic polymer solar cell device is as follows:

[0028] P3: PCBM system: open circuit voltage is 0.77V, short circuit current density is 12.64mA / cm -2 , the fill factor is 0.75, and the photoelectric conversion efficiency is 7.29%.

[0029] P3: ITIC system: open circuit voltage is 0.93V, short circuit current density is 12.56mA / cm -2 , the fill factor is 0.64, and the photoelectric conversion efficiency is 7.47%. The performance of device in embodiment 2 is obviously worse than the device performance in embodiment 1, as image 3 shown.

Embodiment 3

[0030] Example 3: In order to verify that the ternary blend system can enhance spectral complementarity and battery efficiency, we have tested the external quantum efficiency (IPCE) of the device of Example 1 and Example 2.

[0031] Tested in an atmospheric environment with a spot size of 1mm 2 under a tungsten light source simulator. From Figure 4 We can find that the spectral absorption of the device of the embodiment 1 is greatly broadened compared with the device of the embodiment 2, and the external quantum efficiency reaches 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com