Preparation method of zinc ferrite nano-material

A nanomaterial, zinc ferrite technology, applied in the field of preparation of zinc ferrite nanomaterials, can solve the problems of poor selectivity of gas-sensing materials, high working temperature, easy phase transition, etc., and achieves good sensitivity, easy availability of raw materials, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of Fe III -MOF-5 nanomaterials

[0021] Zinc nitrate hexahydrate (19.2 mg), iron acetylacetonate (29 mg), terephthalic acid (4.8 mg), polyvinylpyrrolidone (96 mg) were dissolved in a mixed solution of N,N-dimethylacetamide and ethanol (12.8 mL, V / V=5:3). The above mixture was stirred at room temperature for 10 minutes, then the obtained suspension was transferred into a 20mL reaction kettle and heated at 100°C for 24h, the obtained product was centrifuged with DMF and ethanol successively, and then dried in a vacuum oven at 60°C for 6h. Get the precursor Fe Ⅲ -MOF-5 nanomaterials.

Embodiment 2

[0023] Preparation of Fe III -MOF-5 nanomaterials

[0024] Dissolve zinc nitrate hexahydrate (23.2mg), iron acetylacetonate (30mg), terephthalic acid (5mg), polyvinylpyrrolidone (100mg) in a mixed solution of N,N-dimethylformamide and ethanol (12.8mL , V / V=5:3). The above mixture was stirred at room temperature for 10 minutes, then the obtained suspension was transferred into a 20mL reaction kettle and heated at 140°C for 12h, and the obtained product was centrifuged with DMF and ethanol successively and dried in a vacuum oven at 80°C for 10h. Get the precursor Fe III -MOF-5 nanomaterials.

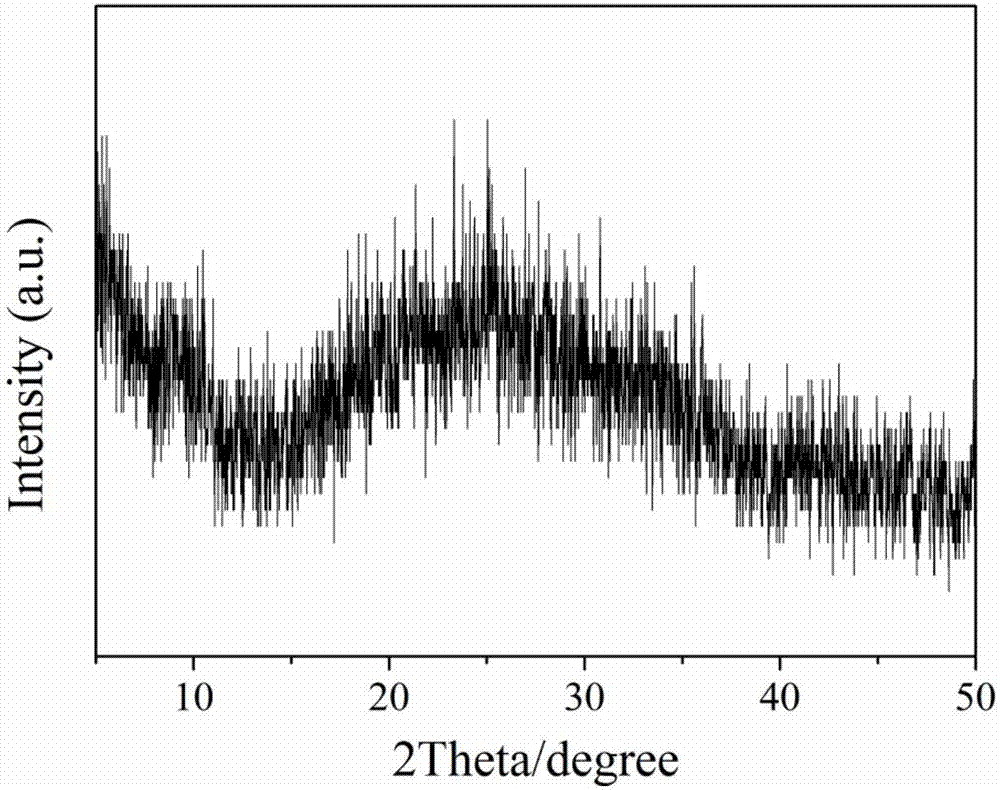

[0025] The structure was confirmed by X-ray powder diffractometer analysis, such as figure 1 The resulting precursor Fe III -MOF-5 nanomaterials have no obvious diffraction peaks, indicating that they are amorphous.

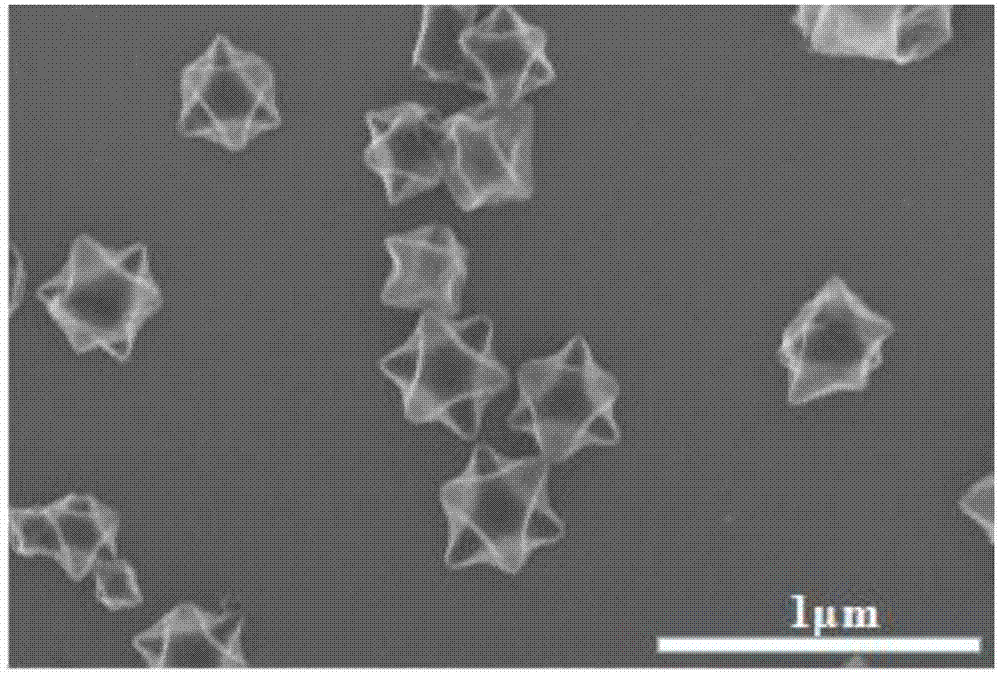

[0026] The obtained Fe was characterized by scanning electron microscopy III - Morphology of MOF-5 nanomaterials. Such as figure 2 As shown, the resulting Fe III -...

Embodiment 3

[0028] Preparation of ZnFe 2 o 4 nanomaterials

[0029] Fe in embodiment 1 or embodiment 2 III - MOF-5 nanomaterials (20 mg) were weighed into a crucible, placed in a muffle furnace, and calcined at a high temperature in an air atmosphere. The calcination temperature is 450°C, the heating rate is 1°C / min, and the calcination time is 2h.

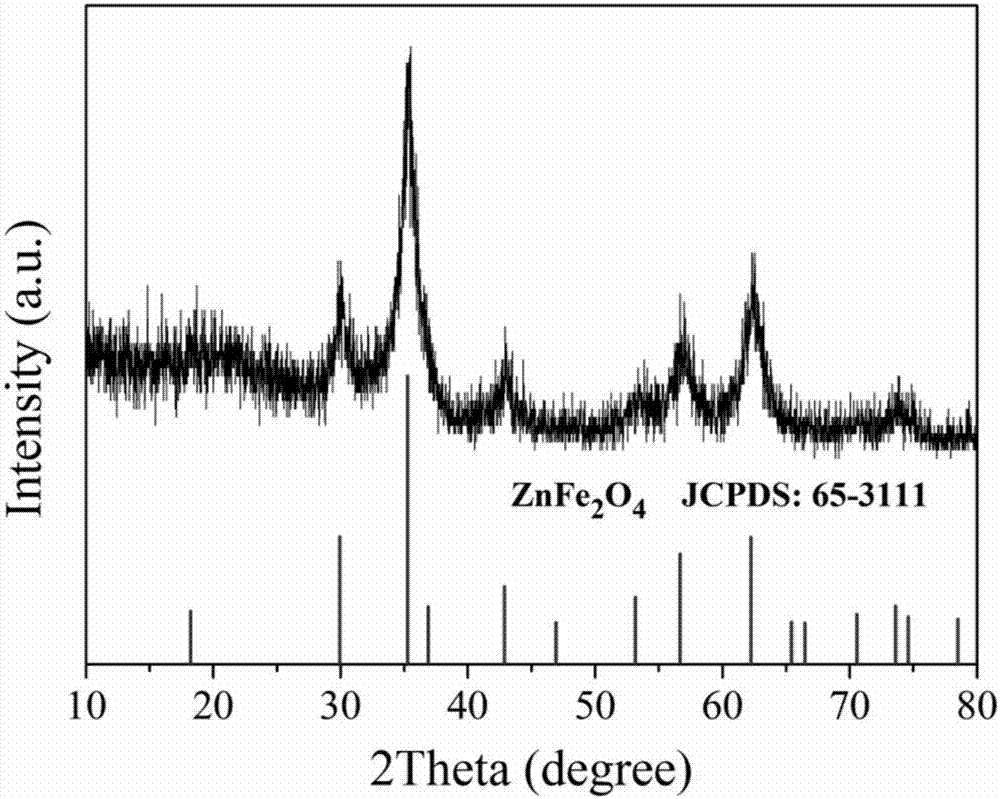

[0030] The structure was confirmed by X-ray powder diffractometer analysis, such as image 3 The nanomaterial shown is a spinel-structured ZnFe 2 o 4 nanomaterials.

[0031] The obtained ZnFe was characterized by scanning electron microscope 2 o 4 Morphology of nanomaterials. Such as Figure 4 As shown, the resulting ZnFe 2 o 4 Nanomaterials have an octahedral structure and a rough surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com