Multi-cathode-compartment denitrifying phosphorus removal electrogenesis device by activated sludge process

A technology of denitrification phosphorus removal and activated sludge method, which is applied in the field of denitrification phosphorus removal power generation device in multiple cathode chambers of activated sludge method, can solve the problems of waste of organic energy, reduce operating costs, reduce equipment capacity, reduce The effect of occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

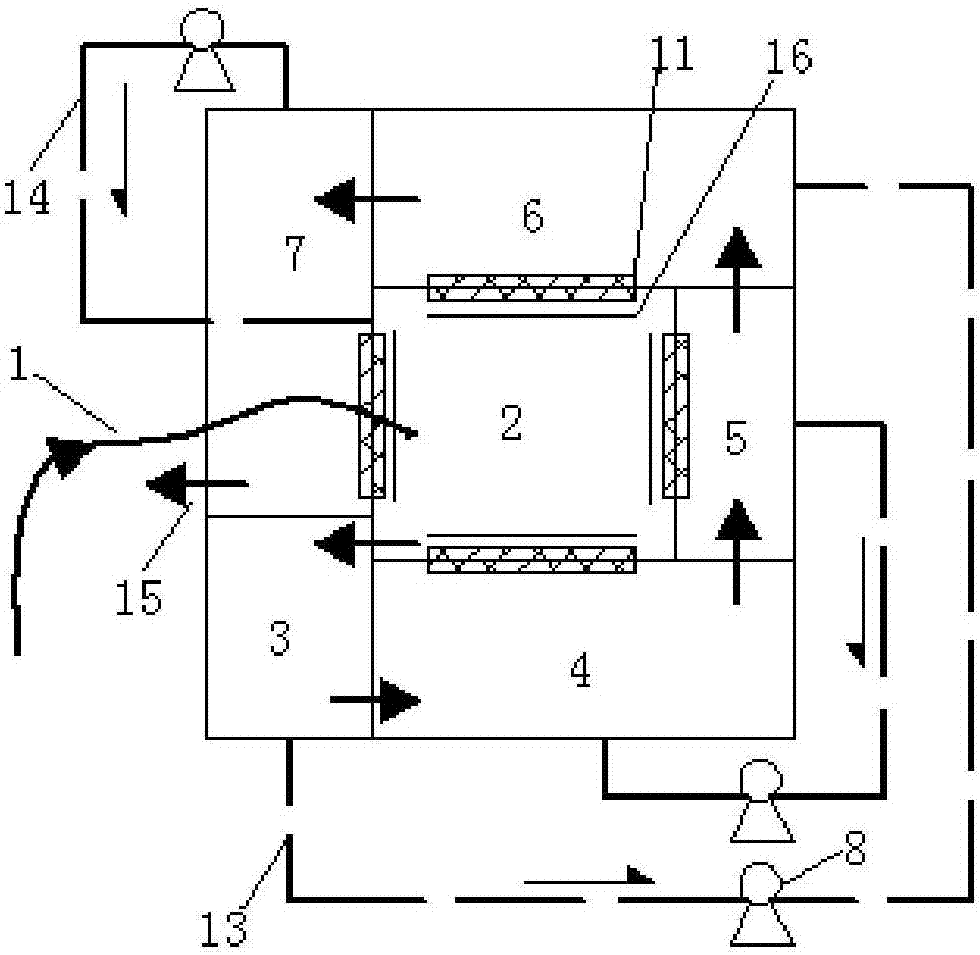

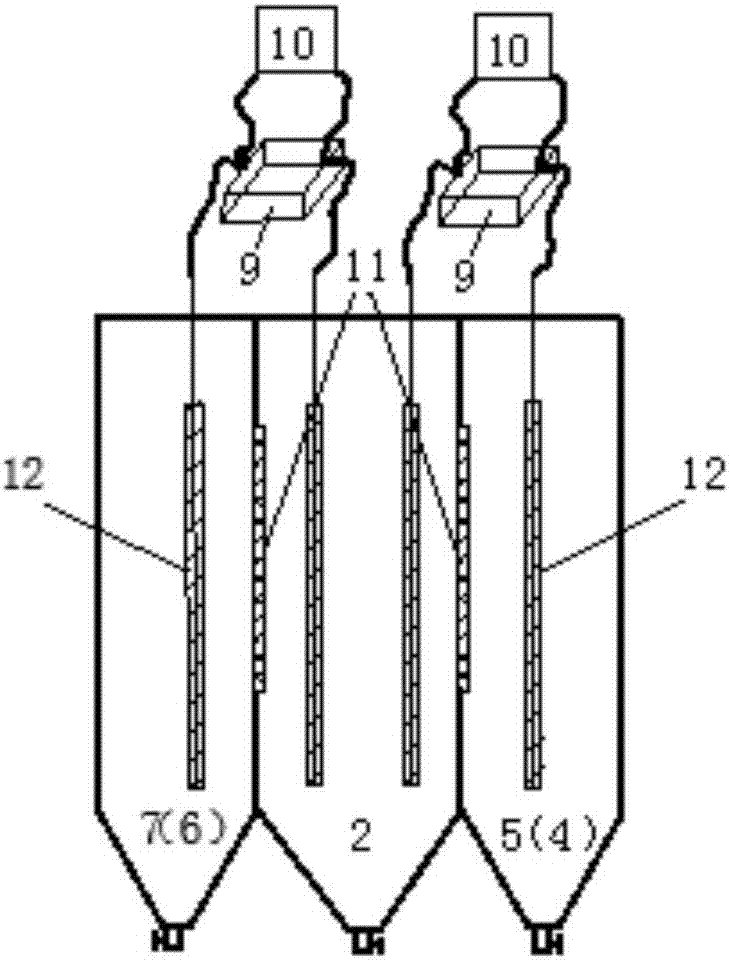

[0021] Example: such as figure 1 As shown, the present invention includes an anaerobic tank 2, a primary sedimentation tank 3, an aerobic tank 4, a secondary sedimentation tank 5, an anoxic tank and a final sedimentation tank 7, which are connected in sequence, wherein the anaerobic tank 2 serves as the anode chamber of the microbial fuel cell The aerobic tank 4, the secondary sedimentation tank 5, the anoxic tank 6 and the final sedimentation tank 7 are used as the cathode chambers of the microbial fuel cell and are arranged around the anaerobic tank. The anode chamber and the cathode chamber are respectively connected with a resistor 9, and the anaerobic tank 2 Proton exchange membrane 11 is installed between the aerobic tank 4, the secondary sedimentation tank 5 and the anoxic tank 6. The primary sedimentation tank 3 and the anoxic tank 6 are connected by a sludge exceeding pipeline 13, and the aerobic tank 4 and the secondary sedimentation tank The tank 5, the final sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com